Comprehensive Guide to Selecting and Installing Your Ideal Bonded Seal Kit for Optimal Performance

Understanding Bonded Seal Kits An Essential Guide

In various industrial applications, ensuring a secure and reliable seal is critical for the integrity of systems that handle fluids and gases. One of the solutions that engineers and technicians often turn to is the bonded seal kit. This article delves into what bonded seal kits are, their components, applications, and the benefits they provide.

What is a Bonded Seal Kit?

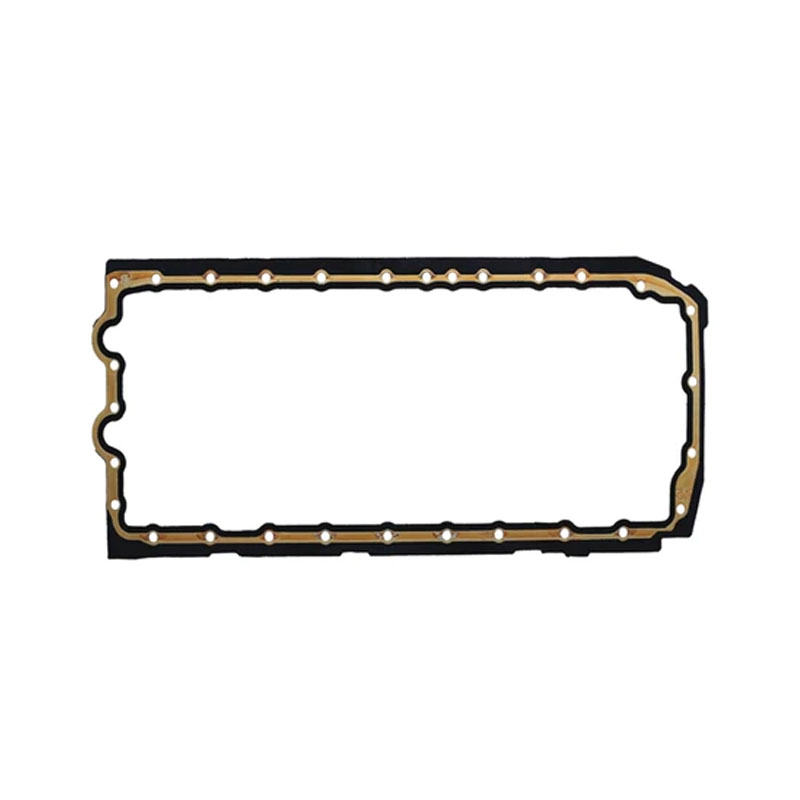

A bonded seal kit consists of a rubber sealing element and a metal washer, designed to provide a more effective sealing solution than traditional methods. The rubber is typically made from materials like nitrile or silicone, which are known for their excellent resistance to a wide range of chemicals and temperature fluctuations. The metal washer is often made from steel or another durable metal, providing structural integrity while enhancing the sealing performance.

The design of the bonded seal allows it to cope with various pressure levels, making it suitable for both low and high-pressure applications. The rubber portion compresses when tightened, creating a tight seal against the mating surfaces, while the metal washer helps to distribute the load and resist extrusion or deformation.

Components of a Bonded Seal Kit

Typically, a bonded seal kit will include

1. Rubber Sealing Element This is the part responsible for creating a seal to prevent leakage. The type of rubber used can be selected based on the application requirements, such as temperature resistance and chemical compatibility.

2. Metal Washer This component provides additional strength and support to the rubber seal, ensuring it stays securely in place and maintains an effective seal under pressure.

3. Installation Tools Depending on the kit, it may also include specific tools to facilitate the installation process, ensuring that the seals are fitted correctly for optimal performance.

Applications of Bonded Seal Kits

Bonded seal kits are widely used in various industries, including automotive, aerospace, construction, and oil and gas

. Here are some specific applicationsbonded seal kit

- Automotive They are commonly employed in engine applications, particularly for sealing oil and coolant passages where high temperatures and pressures are prevalent.

- Aerospace In aerospace applications, these seals must withstand extreme conditions, and bonded seal kits are used to ensure engine integrity and safety.

- Hydraulic Systems In hydraulic applications, bonded seals are essential for preventing leaks in hydraulic cylinders and fittings, maintaining system efficiency, and ensuring safe operation.

- Pneumatic Systems Similar to hydraulic systems, bonded seals are used in pneumatic applications to prevent air leaks, ensuring that systems operate efficiently and safely.

Benefits of Using Bonded Seal Kits

The use of bonded seal kits offers several advantages

1. Enhanced Sealing Performance The combination of rubber and metal provides superior sealing capabilities, reducing the risk of leaks significantly.

2. Ease of Installation These kits are often easier to install compared to traditional sealing methods, saving time and labor costs.

3. Versatility They can be used in a variety of applications, accommodating different pressures and temperatures, which makes them a flexible solution for many industries.

4. Durability The materials used in bonded seal kits are chosen for their durability, ensuring a long service life and reliable performance in harsh environments.

Conclusion

Bonded seal kits are a vital component in a wide range of applications across various industries. Their unique design, which combines a rubber sealing element with a metal washer, results in enhanced sealing capabilities that minimize leaks and improve system reliability. With their ease of installation and versatility, bonded seal kits are a go-to solution for engineers and technicians looking to maintain the integrity of their systems. Whether in automotive, aerospace, or hydraulic applications, the importance of a reliable seal cannot be overstated, making bonded seal kits an essential part of modern engineering solutions.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories