Understanding the Importance and Applications of Flat Rubber Seals in Various Industries

Understanding Flat Rubber Seals An Essential Component in Various Industries

Flat rubber seals are ubiquitous in a multitude of applications across different industries, playing a critical role in ensuring the efficiency and reliability of machinery and equipment. These seals are primarily designed to prevent the passage of fluids, dust, and gas between surfaces, contributing significantly to the overall performance and longevity of products.

Composition and Design

Flat rubber seals are typically made from various types of rubber, such as nitrile, EPDM (ethylene propylene diene monomer), and silicone. Each type of rubber offers different properties, making them suitable for specific environments and applications. For instance, nitrile rubber is known for its excellent resistance to oils and fuels, making it an ideal choice for automotive and industrial usages. On the other hand, EPDM rubber is highly resistant to heat, ozone, and weathering, which is crucial for outdoor applications or environments exposed to harsh weather conditions.

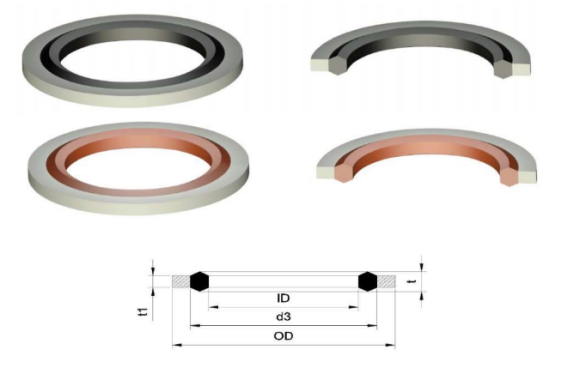

The design of flat rubber seals is often tailored to meet specific dimensional and functional requirements. These seals can come in various shapes, sizes, and thicknesses, allowing for effective sealing in diverse assembly configurations. The flat profile often provides a larger surface area for better contact with the mating surfaces, which enhances their sealing capabilities and minimizes the risk of leaks.

Applications

Flat rubber seals are used in a wide range of applications, spanning across different sectors. In the automotive industry, they are commonly found in engine components, fuel systems, and transmission units. Their ability to withstand extreme temperatures and chemical exposure makes them vital for maintaining the integrity of vehicle systems.

flat rubber seal

In the plumbing and construction sectors, flat rubber seals are essential for water-tight fittings in pipes, faucets, and fixtures. They help prevent leaks, which can lead to water damage and costly repairs. These seals are also used in HVAC systems, where their durability and efficiency contribute to the system’s performance and energy conservation.

In the food and beverage industry, flat rubber seals play a crucial role in ensuring hygiene and safety standards

. Seals used in processing equipment, containers, and packaging must conform to strict regulations to prevent contamination and ensure that products remain safe for consumption.Advantages of Flat Rubber Seals

One of the primary advantages of flat rubber seals is their versatility. They can be manufactured to meet a variety of specifications, making them suitable for use in countless applications. Additionally, rubber seals offer excellent compressibility, allowing them to create a tight seal even on uneven surfaces.

Moreover, flat rubber seals have a relatively low production cost, especially when produced in large quantities. They are lightweight, which helps in reducing shipping costs, and are easy to install and replace, contributing to lower maintenance efforts and costs.

Conclusion

Flat rubber seals are a vital component in many industries, providing effective sealing solutions that enhance the performance and reliability of various products. Their diverse materials, tailored designs, and wide application reach underscore their importance in everyday technology and manufacturing processes. As industries evolve and the demand for more efficient and reliable sealing solutions increases, flat rubber seals are likely to remain a popular choice for engineers and manufacturers worldwide. Their role in providing safety, efficiency, and durability cannot be overstated, making them integral to modern innovations.

-

Understanding Different Types of Oil Drain Plugs: A Comprehensive Guide

News Jun.27,2025

-

The Role of Nylon Washers in Oil Drain Maintenance: A Practical Guide

News Jun.27,2025

-

The Essential Guide to Drain Plug Washers: Types, Uses, and Best Practices

News Jun.27,2025

-

Everything You Need to Know About Washer and Plug Sealing: Polaris-Specific and General Tips

News Jun.27,2025

-

A Comprehensive Guide to Different Types of Oil Drain Plugs for Efficient Maintenance

News Jun.27,2025

-

A Complete Guide to Oil Drain Plug Washers: Tridon and Euro Car Parts Solutions

News Jun.27,2025

-

Understanding Oil Drain Plugs: Types, Issues, and Replacements

News Jun.26,2025

Products categories