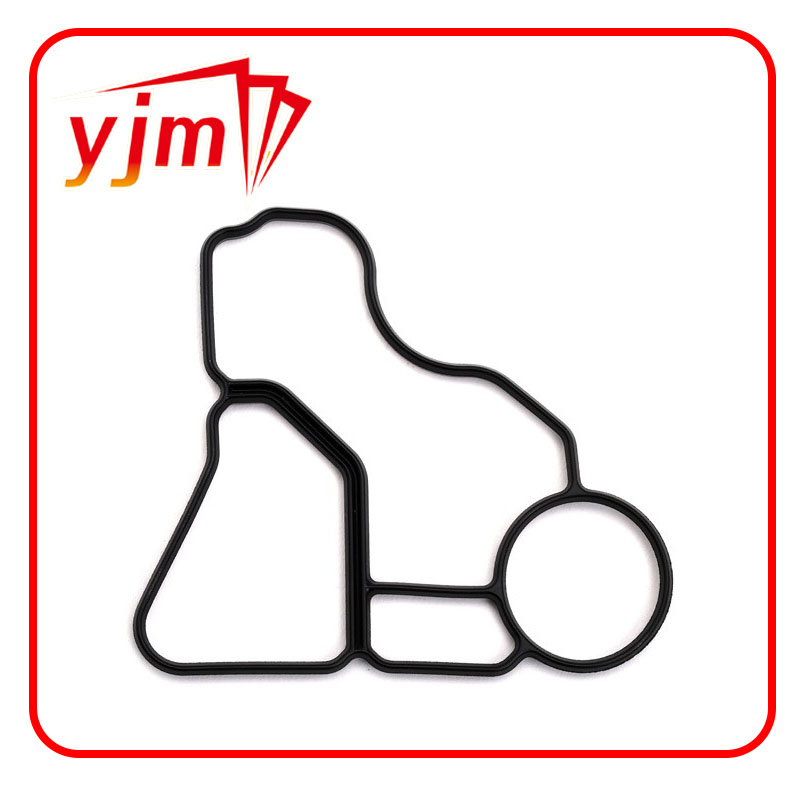

YJM Oil sump gasket 11 13 7 511 224

Real-world experience highlights the importance of proper installation and maintenance in prolonging the life of a stern tube seal. Case studies from reputable maritime companies reveal that even the highest quality seals can fail prematurely if not correctly installed or routinely checked for wear and tear. Periodic inspection, accompanied by proactive maintenance, mitigates the risk of catastrophic failure, thus safeguarding operational integrity. To exemplify the critical role of stern tube seals and substantiate their impact with real-world relevance, consider the scenario of a tanker navigating the high seas. A neglected or improperly chosen seal could lead to adverse consequences, including water ingress, lubricant loss, and eventual damage to the propulsion system. Rectifying such issues entails considerable downtime and cost, disrupting operational schedules and impacting profitability. A deep dive into customer feedback on platforms and forums reveals a consensus on the value of investing in superior quality seals. Shipowners and operators consistently highlight the long-term cost efficiency and peace of mind afforded by choosing seals from trusted manufacturers renowned for durability and robust performance metrics. In conclusion, the selection of a stern tube seal is not merely a transactional choice but a strategic decision with far-reaching implications for a vessel's operational success. Leveraging expertise, authoritativeness, and the collective experience in the field ensures not just compliance with industry standards but also the enhancement of a vessel’s reliability and efficiency. As with any critical decision in marine engineering, thorough due diligence—grounded in the principles of E-E-A-T—should guide the selection process, ensuring not only optimal functionality but also profitability and environmental stewardship.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories