Trailer Wheel Bearing Seals

Understanding Trailer Wheel Bearing Seals

When it comes to maintaining your trailer, one crucial component that often goes overlooked is the wheel bearing seals. These small yet essential seals play a significant role in ensuring the longevity and smooth operation of your trailer's wheels. In this article, we will delve into the importance of trailer wheel bearing seals, their functions, and tips for maintenance.

What Are Wheel Bearing Seals?

Wheel bearing seals are designed to protect the wheel bearings from dirt, water, and other contaminants that could cause damage. They serve as a barrier, preventing grease from leaking out and ensuring that the bearings remain lubricated. Properly functioning wheel bearing seals help reduce friction and heat, which can lead to premature wear and failure of the bearings.

Importance of Keeping Wheel Bearing Seals in Good Condition

Regularly inspecting and maintaining wheel bearing seals is critical for several reasons. First, damaged or worn seals can lead to contamination of the bearings. Once dirt or water infiltrates the bearing assembly, it can cause significant damage, ultimately leading to costly repairs or even complete replacement of the wheel bearings. This can be particularly problematic for trailers that frequently travel on rough or wet roads.

Second, the failure of a wheel bearing seal can result in grease leakage, which can compromise lubrication and heat dissipation. Without adequate lubrication, the bearings can overheat, leading to severe damage or failure. Regular checks for signs of leakage can help you catch potential issues early, saving you time and money in the long run.

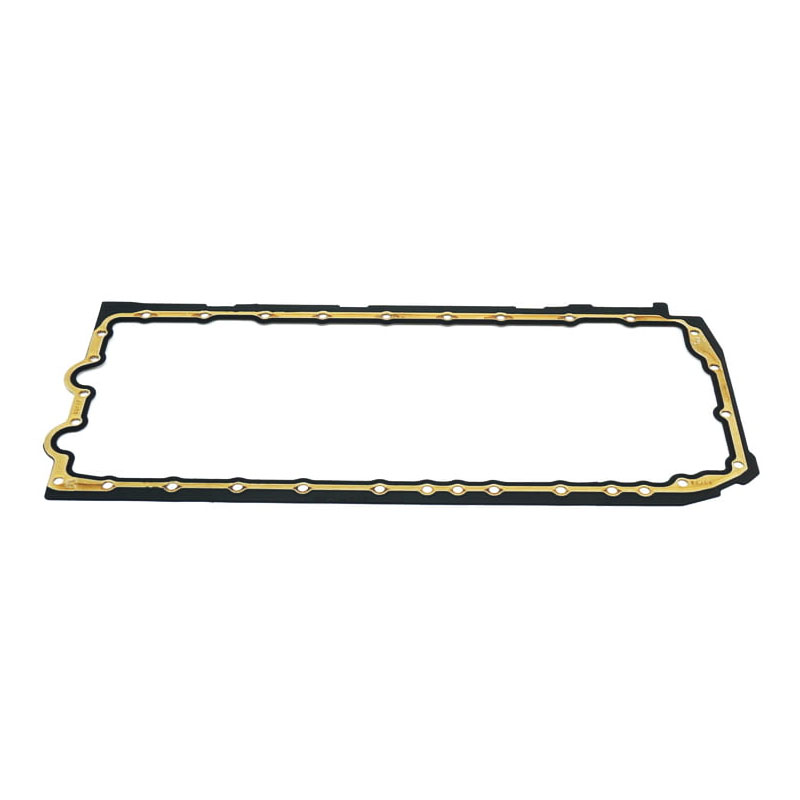

trailer wheel bearing seals

Tips for Maintaining Wheel Bearing Seals

1. Routine Inspections Regularly check the condition of your wheel bearing seals as part of your trailer maintenance routine. Look for signs of wear, cracks, or any signs of grease leakage.

2. Re-greasing Ensure that the bearings are properly greased at intervals recommended by the manufacturer. This ensures that the seals can do their job effectively.

3. Replace When Necessary If you notice any signs of damage during your inspections, don’t hesitate to replace the seals immediately. It's a relatively small investment that can prevent larger, more expensive problems down the line.

4. Proper Installation When replacing wheel bearing seals, make sure they are installed correctly. Improper installation can lead to leaks and increased wear.

Conclusion

Trailer wheel bearing seals are essential components that protect your trailer’s wheel bearings from damage and contamination. By keeping these seals in good condition through regular inspections and maintenance, you can ensure the safety and longevity of your trailer. Taking these simple steps can save you from costly repairs and keep your trailer performing at its best on every journey.

-

Understanding Different Types of Oil Drain Plugs: A Comprehensive Guide

News Jun.27,2025

-

The Role of Nylon Washers in Oil Drain Maintenance: A Practical Guide

News Jun.27,2025

-

The Essential Guide to Drain Plug Washers: Types, Uses, and Best Practices

News Jun.27,2025

-

Everything You Need to Know About Washer and Plug Sealing: Polaris-Specific and General Tips

News Jun.27,2025

-

A Comprehensive Guide to Different Types of Oil Drain Plugs for Efficient Maintenance

News Jun.27,2025

-

A Complete Guide to Oil Drain Plug Washers: Tridon and Euro Car Parts Solutions

News Jun.27,2025

-

Understanding Oil Drain Plugs: Types, Issues, and Replacements

News Jun.26,2025

Products categories