Exploring the Benefits and Applications of Pan Gaskets in Industrial Settings

The Importance of Pan Gaskets in Mechanical Applications

In the world of mechanical engineering and design, one of the often-overlooked yet critical components is the gasket. Gaskets play an essential role in sealing joints between two or more surfaces, preventing leaks and ensuring efficient operation. Among the various types of gaskets, the pan gasket stands out, particularly in automotive and industrial applications.

What is a Pan Gasket?

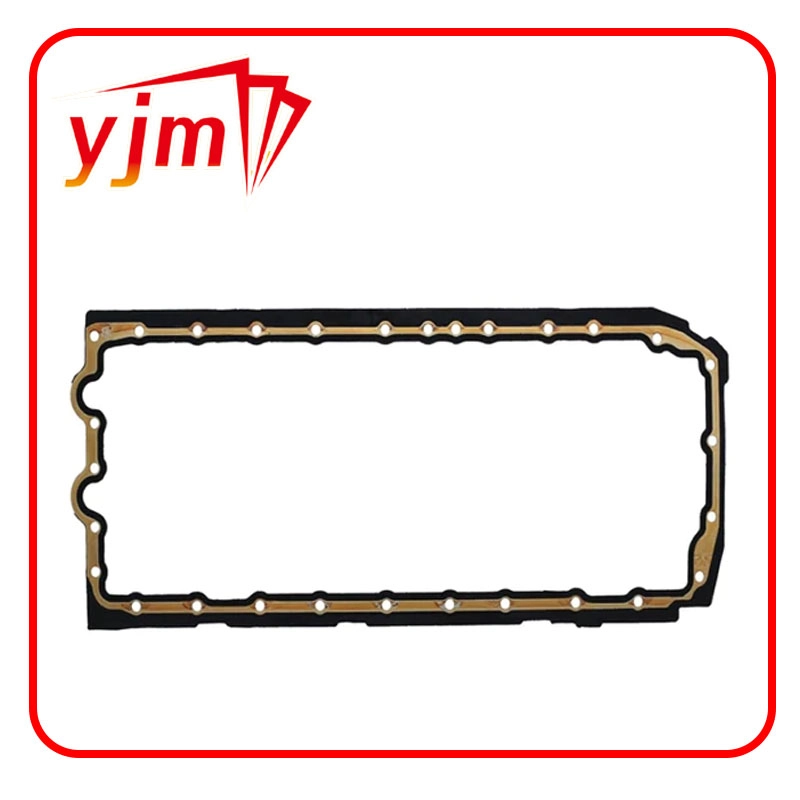

A pan gasket is a specific type of gasket used primarily at the joint where the oil pan connects to the engine block in vehicles. The oil pan, housing the engine’s oil supply, must be sealed tightly to prevent any oil leaks that could lead to severe engine damage. This is where the pan gasket comes into play.

Typically made of materials like rubber, cork, or composite materials, pan gaskets are designed to withstand vibrations, temperature changes, and exposure to harsh chemicals. The choice of material is crucial, as it needs to provide a reliable seal while also being resilient enough to handle the operating conditions of the engine or machinery.

The Function of Pan Gaskets

Pan gaskets serve several functions within an engine. First and foremost, they provide a leak-proof seal between the oil pan and the engine block. This prevents the engine oil from leaking out, which is essential for maintaining adequate lubrication within the engine. Insufficient lubrication can lead to increased friction and, eventually, engine wear or failure.

Additionally, pan gaskets help to maintain the necessary pressure within the oil pan. Proper pressure ensures that oil is circulated efficiently throughout the engine, allowing all components to operate smoothly. A malfunctioning gasket can lead to pressure loss, resulting in oil not being adequately circulated.

Choosing the Right Pan Gasket

pan gasket

Selecting the appropriate pan gasket for a specific application is crucial for optimal performance. Factors such as temperature, chemical exposure, and mechanical stress need to be considered. For instance, high-performance engines may require high-temperature resistant gaskets to withstand extreme conditions.

Also, the surface finish of the mating parts is important. A rough or damaged surface can compromise the seal, leading to leaks. Therefore, proper preparation of the surfaces and careful installation of the gasket is essential for ensuring a successful seal.

Installation and Maintenance

Installing a pan gasket requires careful attention to detail. Before installation, both mating surfaces should be thoroughly cleaned to remove any old gasket material, grime, or oil. This ensures a proper bond between the surfaces and the gasket.

During installation, it is crucial to apply the correct amount of torque to the bolts that secure the oil pan. Over-tightening can damage the gasket and lead to leaks, while under-tightening may not provide a sufficient seal. Following the manufacturer's specifications for torque is essential for achieving the best results.

Once installed, routine maintenance can help extend the life of the pan gasket. Regularly checking the oil levels and monitoring for any signs of leaks can alert an operator to potential issues before they escalate into significant problems.

Conclusion

Pan gaskets, although often overlooked, are vital components in the machinery and automotive industries. Their role in preventing oil leaks and maintaining proper lubrication is indispensable for the health and longevity of engines and mechanical systems. Careful selection, installation, and maintenance of pan gaskets not only ensure the smooth operation of engines but also contribute to overall vehicle performance and reliability.

In an era where efficiency and sustainability are more critical than ever, paying attention to components such as pan gaskets can lead to substantial benefits. As engineers and mechanics continue to innovate and improve mechanical designs, understanding the importance of each part, including the humble pan gasket, ensures that we keep our machinery running smoothly and efficiently.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories