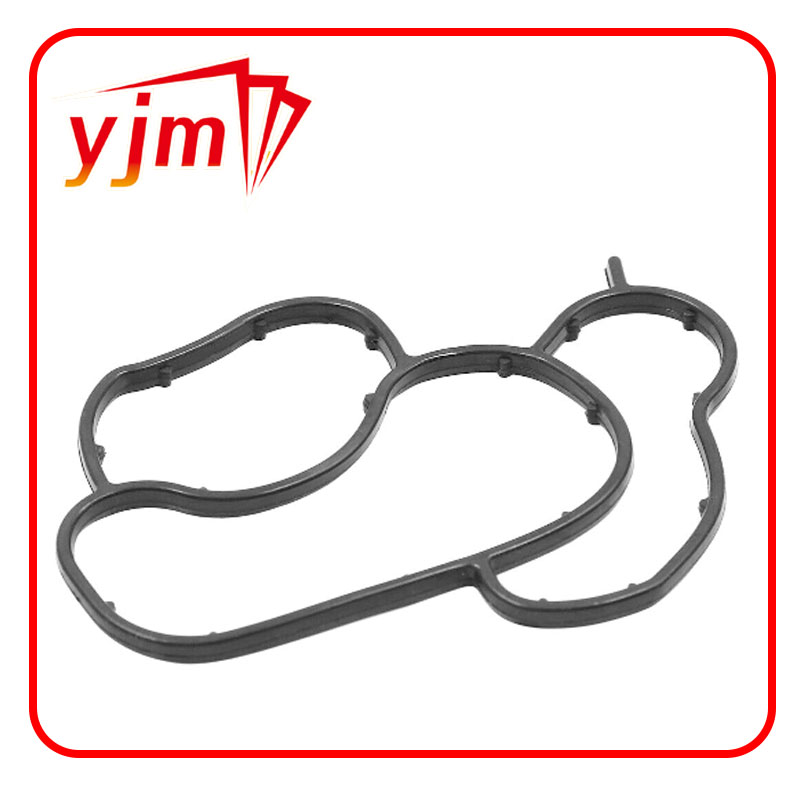

flat o ring seal

Understanding Flat O-Ring Seals Applications and Benefits

Flat O-ring seals are essential components widely used in various industries to create leak-proof seals in mechanical assemblies. Unlike traditional O-rings, which have a round cross-section, flat O-rings feature a rectangular or square profile. This design adaptation allows them to provide superior sealing capabilities in specific applications, making them an integral part of modern engineering solutions.

The primary function of a flat O-ring seal is to prevent the escape of fluids and gases between two surfaces. This is particularly important in applications where pressure differs on either side of the seal. For instance, flat O-rings are commonly used in hydraulic and pneumatic systems, where they play a crucial role in maintaining system integrity and preventing leaks that could lead to catastrophic failures or operational inefficiencies.

Understanding Flat O-Ring Seals Applications and Benefits

Flat O-ring seals are also known for their ease of installation. Their flat shape allows them to fit snugly in grooves, providing a reliable seal without the need for complex components or tools. This ease of use translates into reduced assembly times and lower labor costs, contributing to enhanced operational efficiency for manufacturers.

flat o ring seal

In addition to their practical benefits, flat O-rings offer superior resistance to wear and deformation. Unlike traditional O-rings, which may experience compression set over time, flat O-rings maintain their shape and sealing properties under prolonged exposure to pressure and environmental factors. This durability ensures a longer service life, leading to fewer replacements and maintenance interventions, thus optimizing overall equipment reliability.

Furthermore, the design of flat O-ring seals enables them to distribute stress evenly across the surface, reducing the risk of localized failure. This characteristic is particularly important in high-pressure applications, where uneven stress distribution can lead to premature seal failure and costly downtime.

Despite their many advantages, selecting the right flat O-ring seal for a given application requires careful consideration of various factors, including the types of fluids or gases being sealed, the operating temperature and pressure, and the compatibility of the sealing material with the application environment. Proper material selection and design are crucial to ensuring optimal sealing performance and extending the lifespan of the seal.

In conclusion, flat O-ring seals represent a critical innovation in sealing technology. Their unique design, versatility in material selection, ease of installation, and durability make them indispensable in various industries. As technology continues to evolve, the importance of reliable sealing solutions, such as flat O-ring seals, will only increase, driving further advancements in seal design and application to meet the demands of modern engineering challenges.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories