Shaft Seal Selection Guide Based on Size for Optimal Performance and Efficiency

Understanding Shaft Seals by Size A Comprehensive Guide

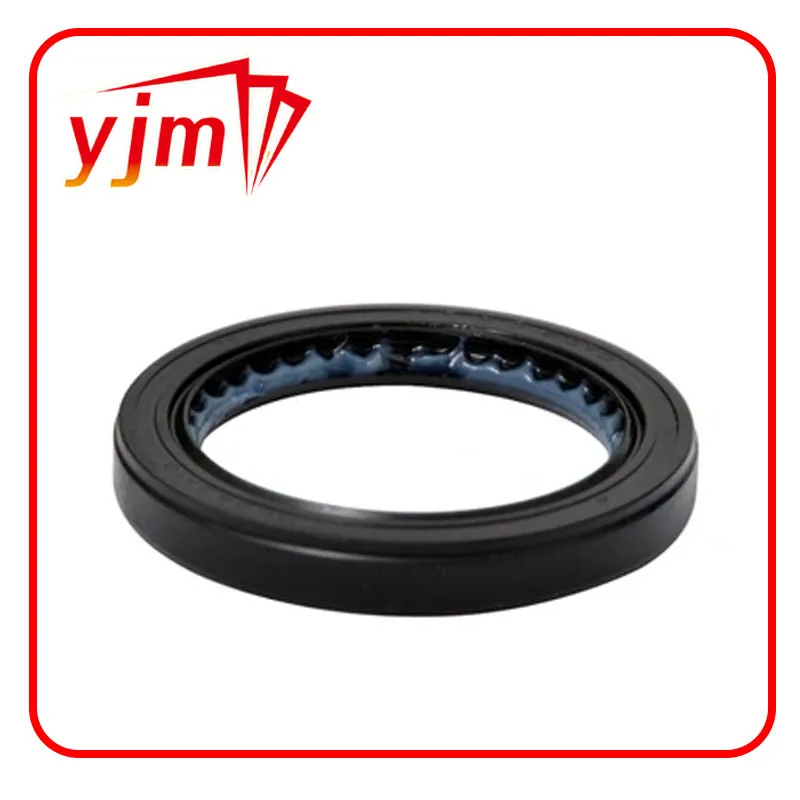

Shaft seals are essential components in many mechanical systems, playing a crucial role in maintaining the integrity and efficiency of rotating equipment. They are designed to prevent fluids from leaking out of the machinery while keeping contaminants from entering. This article delves into the different sizes of shaft seals, their significance, applications, and how to select the right size for your specific needs.

What are Shaft Seals?

Shaft seals are specialized seals that fit around a rotating shaft. They are widely used in various applications, including automotive engines, HVAC systems, hydraulic pumps, and industrial machinery. The primary purpose of a shaft seal is to create a barrier that minimizes leakage of lubricants and prevents the ingress of dirt and moisture, which can lead to equipment failure.

Importance of Size in Shaft Seals

The effectiveness of a shaft seal is closely linked to its size. Choosing the right size is essential for proper sealing and optimal performance. If the seal is too large, it may not fit snugly around the shaft, leading to leaks. Conversely, a seal that is too small will not fit correctly and may also fail. Additionally, the size can impact the seal’s ability to withstand pressure, temperature, and rotational speeds.

Categories of Shaft Seal Sizes

Shaft seals come in various sizes, classified into standard and custom dimensions. Standard sizes are readily available and are suitable for most applications. These seals can be found in various dimensions, including outer diameter (OD), inner diameter (ID), and width. On the other hand, custom seals are designed to meet specific dimensional requirements when standard sizes do not suffice.

1. Standard Sizes These are commonly used in numerous applications and are manufactured to fit popular shaft dimensions. They facilitate quicker and less expensive maintenance since they can be replaced easily without special manufacturing processes. 2. Custom Sizes For specialized machinery or unique systems, custom shaft seals are required. Manufacturers can design seals tailored to specific dimensions and specifications, ensuring an exact fit for the application.

Selecting the Right Shaft Seal Size

When selecting a shaft seal size, there are several factors to consider

shaft seals by size

- Shaft Diameter Measure the shaft’s outside diameter accurately. This measurement is critical as it determines the inner diameter of the seal. - Operating Conditions Consider the operational environment, including temperature, pressure, and the nature of the fluid being sealed. Different seal materials and designs can be chosen based on these conditions. - Installation Space Ensure there is adequate space for installation and maintenance. The outer diameter of the seal must fit within the housing or equipment without obstruction.

- Material Compatibility Choose a seal material that is compatible with the fluids involved in the application. Common materials include rubber, polyurethane, and various plastics, each offering different chemical resistance and temperature stability.

Applications of Shaft Seals

Shaft seals find application across diverse industries

- Automotive They are used in engines to prevent oil leaks and keep contaminants out, ensuring the engine runs smoothly.

- Hydraulics In hydraulic systems, seals prevent fluid leakage and maintain pressure, which is vital for effective machine operation.

- Industrial Equipment Shaft seals in pumps and conveyors protect the internal mechanisms and extend the lifespan of the equipment.

Conclusion

Choosing the right shaft seal size is critical for maintaining the efficiency and longevity of machinery. By understanding the importance of size, knowing the categories of shaft seals available, and considering the specific requirements of your application, you can select the correct seal to ensure optimal performance. Whether opting for standard or custom sizes, it's essential to work closely with manufacturers and suppliers who can provide the necessary specifications and expertise to meet your needs.

In summary, shaft seals are indispensable components in any application involving rotating machinery. Their proper sizing is crucial for effective sealing, making it essential for engineers and technicians to choose carefully. By paying attention to the dimensions, materials, and operating conditions, you can ensure the reliability and efficiency of your machinery.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories