Exploring Various Types of Lip Seals for Enhanced Performance and Reliability in Mechanical Applications

Understanding Lip Seal Types A Comprehensive Overview

Lip seals, commonly referred to as oil seals or rotary shaft seals, play a pivotal role in various machinery and automotive applications. Their primary function is to prevent the leakage of fluids, such as oil or grease, while simultaneously keeping contaminants, like dust and dirt, from entering the system. Given the variety of environments in which these seals are used, different types of lip seals are designed to meet specific requirements. In this article, we will explore the various lip seal types and their unique characteristics.

1. Nitrile Rubber Lip Seals (NBR)

Nitrile rubber is a synthetic rubber that is widely used in lip seals due to its excellent resistance to oil and various fuels. NBR lip seals are commonly utilized in automotive applications, where they are required to withstand exposure to engine oils and hydrocarbons. They perform well in a range of temperatures, typically from -30°C to +100°C. However, they may degrade when exposed to ozone or certain chemicals, which limits their usage in specific applications.

2. Fluoroelastomer Lip Seals (FKM)

Fluoroelastomers, commonly known by their trade name, Viton, are another popular choice for lip seals. They exhibit superior resistance to high temperatures, aggressive chemicals, and ozone. FKM lip seals can operate effectively in temperatures ranging from -20°C to +200°C, making them suitable for automotive and aerospace applications where extreme conditions are prevalent. Their durability under harsh environmental factors often justifies their higher cost compared to nitrile seals.

3

. Polyurethane Lip SealsPolyurethane is recognized for its outstanding abrasion resistance and mechanical strength. Polyurethane lip seals are ideal for applications where there is high wear and tear, such as in hydraulic systems. They perform well in a temperature range of -30°C to +90°C. Unfortunately, polyurethane seals can be less effective in resisting oil, which makes them less popular in automotive applications when compared to NBR and FKM.

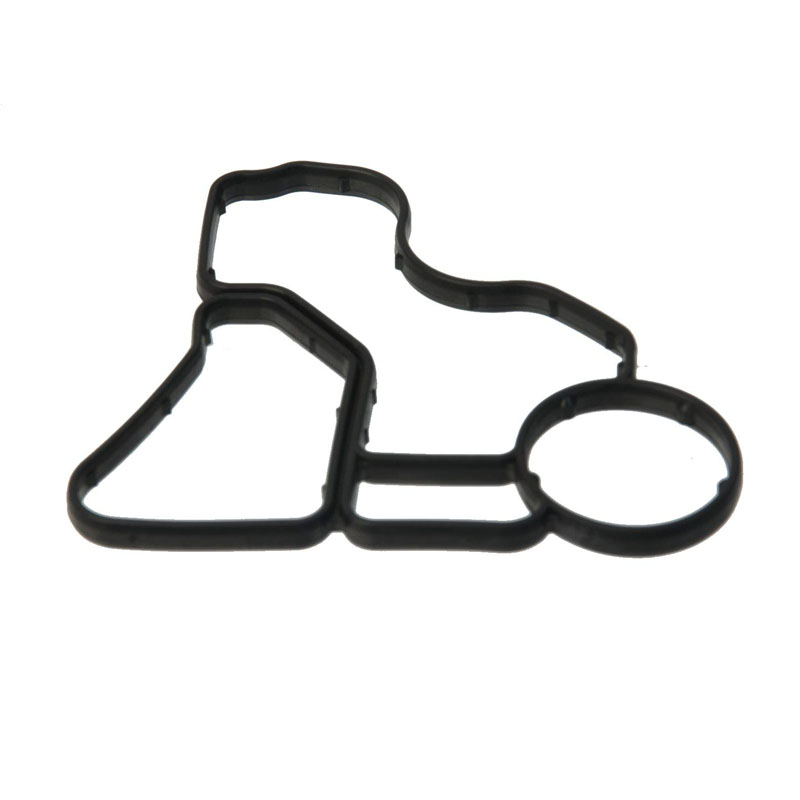

lip seal types

4. Silicone Lip Seals

Silicone lip seals are distinguished by their exceptional temperature resilience and flexibility. They can withstand extreme temperatures ranging from -50°C to +200°C. This makes them an excellent choice for sealing applications involving food processing, pharmaceuticals, and other industries requiring cleanliness and high thermal resistance. However, they are less effective in contact with oils and fuels, which limits their use in automotive applications.

5. Metal Shell Lip Seals

Metal shell lip seals involve a combination of rubber or elastomeric lip and a metal casing, providing additional stability and strength. These seals are designed for heavy-duty applications and can withstand higher pressures compared to typical rubber lip seals. They are often employed in agricultural machinery, construction equipment, and other industrial applications that require robust sealing solutions.

6. Dual Lip Seals

Dual lip seals, often referred to as double-lip seals, consist of two sealing lips which provide an additional barrier against leakage and contamination. They are particularly beneficial in applications where reliability is critical, such as in rotating machinery and gearbox applications. The dual configuration helps in managing dynamic pressure fluctuations and enhancing sealing performance.

Conclusion

Choosing the right type of lip seal is crucial for the longevity and efficiency of machinery and systems. Each type of lip seal has its unique advantages and considerations, and understanding these can help engineers and technicians make informed decisions. Factors such as temperature, chemical resistance, and application-specific requirements must be taken into account to ensure optimal performance. As technology advances, new materials and designs will likely emerge, further expanding the possibilities and efficacy of lip seal solutions.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories