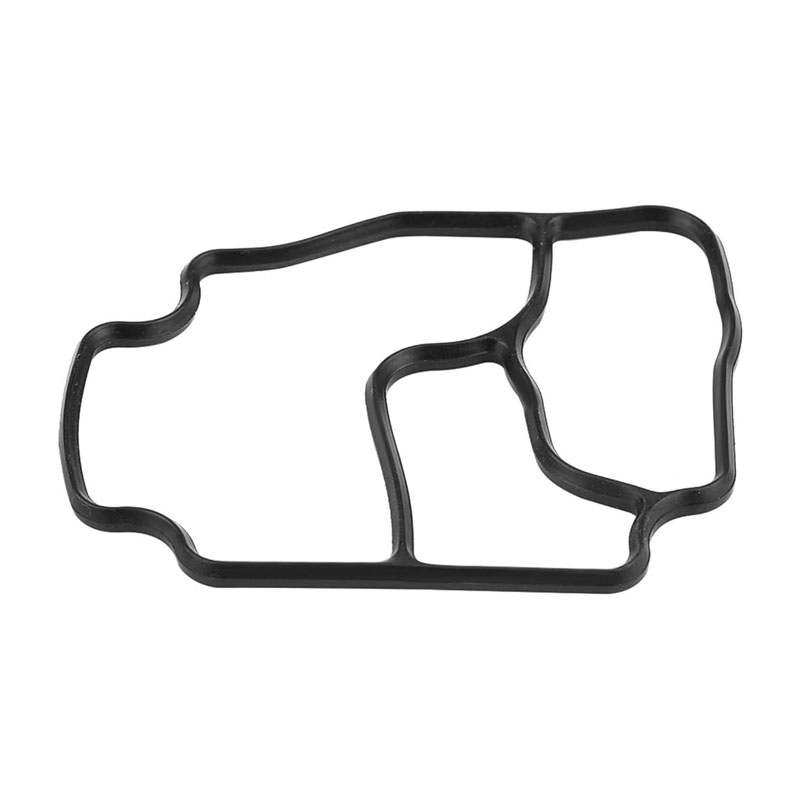

wheel hub grease seal

Understanding Wheel Hub Grease Seals

In the realm of automotive maintenance and repair, the wheel hub grease seal is often overlooked, yet it plays a critical role in ensuring the smooth and efficient functioning of vehicle wheels. This article delves into the importance of grease seals, their types, installation, maintenance, and signs of failure.

What is a Wheel Hub Grease Seal?

A wheel hub grease seal is a mechanical component designed to prevent the leakage of lubricants from the wheel hub assembly while also blocking contaminants from infiltrating the hub. It serves as a barrier between the wheel bearings—components essential for allowing the wheels to rotate with minimal friction—and the external environment. By keeping the grease in and dirt out, the seal helps to extend the life of the bearings and the overall wheel assembly.

Types of Wheel Hub Grease Seals

There are several types of grease seals used in wheel hubs, each with distinct features catering to various vehicle requirements

1. Lip Seals These are the most common types of grease seals. They have a flexible lip that makes contact with the rotating shaft, creating a tight seal. Lip seals are effective at retaining lubricants and preventing contamination.

2. Spring-loaded Seals These seals consist of an internal spring that helps maintain the contact pressure between the seal lip and the surface of the shaft. This design is particularly useful in applications with dynamic movements, as it compensates for wear and maintains sealing integrity.

3. Metallic Seals Although less common, metallic seals offer extreme resistance to high temperatures and pressures. They are typically used in specialized applications where conventional seals may fail.

4. Flanged Seals These seals have a flange that fits into a housing, providing additional stability and ease of installation. They are often used in automotive applications where space constraints exist.

Installation of Wheel Hub Grease Seals

Installing wheel hub grease seals requires precision. A proper installation process ensures effective sealing and longevity. Here are the general steps for installation

wheel hub grease seal

1. Preparation Clean the mating surfaces thoroughly to remove any debris or old seal material that could compromise the seal.

2. Alignment Properly align the seal to avoid misinstallation, which could lead to premature failure.

3. Installation Aid Use a seal driving tool or a suitable object to gently tap the seal into place. It’s crucial not to damage the seal lip during this process.

4. Lubrication Apply a small amount of grease to the seal lip before installation. This helps reduce friction and increases the lifespan of the seal.

5. Final Inspection Once installed, inspect the seal to ensure it sits evenly with no gaps or distortions.

Maintenance and Signs of Failure

Regular maintenance of wheel hub grease seals can prevent costly repairs and ensure vehicle safety. Here are some maintenance tips

- Regular Inspections Check for signs of grease leakage or contaminants around the wheels. - Grease Replacement Ensure that the wheel bearings are adequately lubricated with quality grease. Replacing grease periodically helps maintain the seal's integrity. - Monitor Performance Pay attention to any changes in wheel performance, such as noise or vibration, which could indicate a failing seal.

Signs of failure in a wheel hub grease seal include visible grease leaks, unusual noise from the wheel area, or increased temperature in the wheel hub. Prompt attention to these signs can prevent further deterioration of the wheel bearings and other components.

Conclusion

The wheel hub grease seal may be a small component, but its importance in vehicle maintenance cannot be overstated. By understanding its purpose, types, installation, and maintenance, vehicle owners can ensure a longer lifespan for their wheel bearings and enhance overall vehicle performance. Regular checks and timely replacements will lead to smoother rides and safer driving experiences. Investing in quality grease seals and proper maintenance is a step towards extending the life of any vehicle's critical components.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories