Understanding the Functionality and Benefits of V Ring Seals in Mechanical Applications

Understanding V Ring Seals A Comprehensive Overview

V ring seals, also known simply as V seals, are essential sealing components widely used in various industrial applications. These seals are known for their unique design and functionality, which helps prevent the ingress of contaminants while retaining lubricants within machinery. In this article, we will explore the structure, working principle, benefits, and applications of V ring seals, shedding light on why they are favored in many engineering contexts.

Structure and Design

The V ring seal is characterized by its distinctive V-shaped cross-section, which is predominantly made of elastomeric materials such as rubber or synthetic polymers. This design allows the seal to fit snugly around a rotating shaft, creating a tight seal that can withstand dynamic movements. The flexibility of the V shape helps maintain contact with the shaft even during fluctuations in speed or direction, making it an ideal choice for applications involving rotation.

The outer side of the seal is typically flat, which provides a tight fit against the housing and aids in preventing leaks. The inner side's angle allows for effective sealing against the rotating shaft, ensuring a minimal gap that can be further enhanced with proper installation techniques.

Working Principle

The working principle of a V ring seal is relatively straightforward. When installed on a shaft, the seal exerts a spring-like force against the rotating surface due to its design and material properties. As the shaft rotates, the seal adapts to any lateral or axial movements, maintaining contact and creating a barrier that keeps lubricants in and contaminants out.

V ring seals are particularly effective in applications where there is a combination of rotary and axial movements. The dynamic contact with the shaft helps eliminate areas where dirt or other particles might infiltrate, ensuring that machinery operates smoothly and effectively.

Benefits

One of the main advantages of V ring seals is their versatility. They can be used in a broad range of applications across different industries, including automotive, aerospace, and manufacturing. Some key benefits include

1. Effective Sealing V ring seals provide excellent sealing capabilities, preventing not only the leakage of lubricants but also the entry of dust, dirt, and other contaminants.

2. Low Friction The design minimizes friction between the seal and the shaft, allowing for smoother operation and less wear on both components.

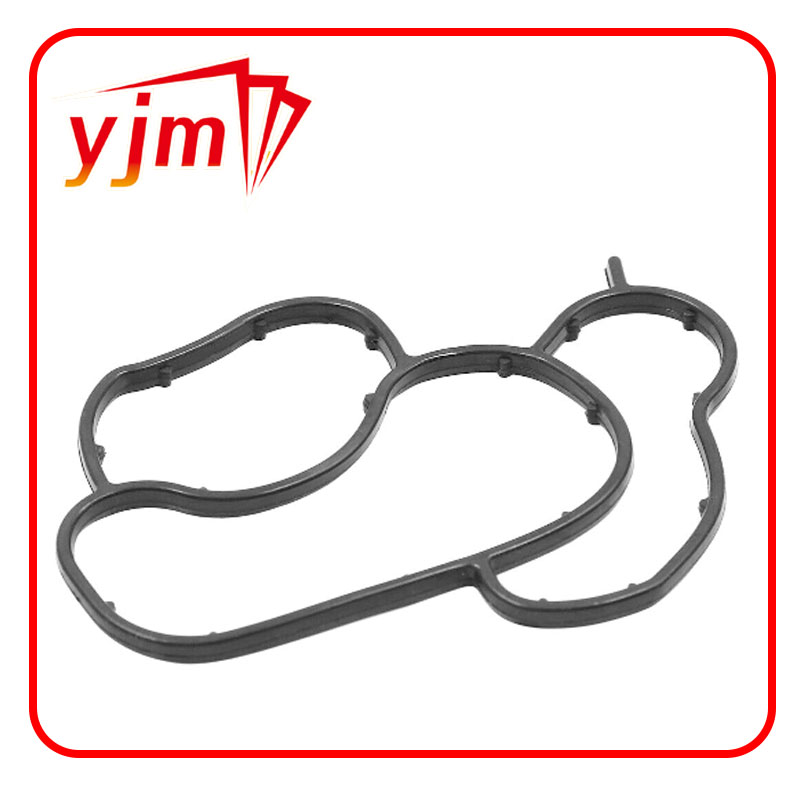

v ring seal

3. Simple Installation V ring seals are easy to install, requiring minimal tools and time. This can lead to reduced downtime during maintenance or assembly operations.

4. Cost-Effective Due to their durability and effectiveness, V rings can significantly reduce maintenance costs associated with leaks and failures.

5. Wide Compatibility They can be used with various shaft diameters and in numerous environmental conditions, making them suitable for diverse applications.

Applications

V ring seals are employed in numerous sectors due to their reliability and performance. Common applications include

- Automotive Industry Used in wheel bearings, engine components, and transmission assemblies to keep lubrication intact and prevent contamination.

- Manufacturing Equipment Essential in gearboxes, pumps, and compressors where axial and radial movements are frequent.

- Aerospace Used within various systems to ensure the reliability of critical components by providing airtight seals.

- Heavy Machinery In excavators, drills, and other equipment to protect against dirt ingress and maintain lubrication of moving parts.

Conclusion

V ring seals play a crucial role in modern engineering, providing effective sealing solutions across various industries. Their unique design, combined with the ability to maintain contact with rotating shafts, makes them an indispensable component for ensuring efficiency and longevity in machinery. As industries continue to evolve, the demand for reliable sealing solutions will only increase, underscoring the importance of V ring seals in contemporary applications.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories