Understanding the Importance of Transmission Shaft Seals for Vehicle Performance and Maintenance

Understanding Transmission Shaft Seals Importance, Functionality, and Maintenance

Transmission shaft seals play a critical role in the operation and longevity of various machinery, particularly in vehicles and industrial equipment. As essential components, these seals are designed to prevent fluid leaks and keep contaminants out of the gearbox or transmission system. This article will delve into the importance, functionality, and maintenance of transmission shaft seals, highlighting their significance in ensuring efficient operations.

The Importance of Transmission Shaft Seals

Transmission systems rely on the smooth operation of numerous components, including gears, clutches, and bearings. Transmission shaft seals serve as the first line of defense against the ingress of dirt, dust, and other external contaminants that could compromise the integrity of the internal systems. Additionally, they prevent the loss of vital lubricating fluids that reduce friction and wear within the transmission. The failure of these seals can lead to severe damage, resulting in costly repairs and increased maintenance downtime. Therefore, investing in high-quality seals is critical for the health of any transmission system.

Functionality of Transmission Shaft Seals

Transmission shaft seals are typically made from durable materials such as rubber, polyurethane, or specialized elastomers. These materials are designed to withstand extreme temperatures, pressures, and chemical exposure, ensuring that the seals remain effective over time. The primary function of a transmission shaft seal is to provide a tight barrier around the rotating shaft, which helps to contain the lubricating fluid within the transmission housing while preventing outside contaminants from entering.

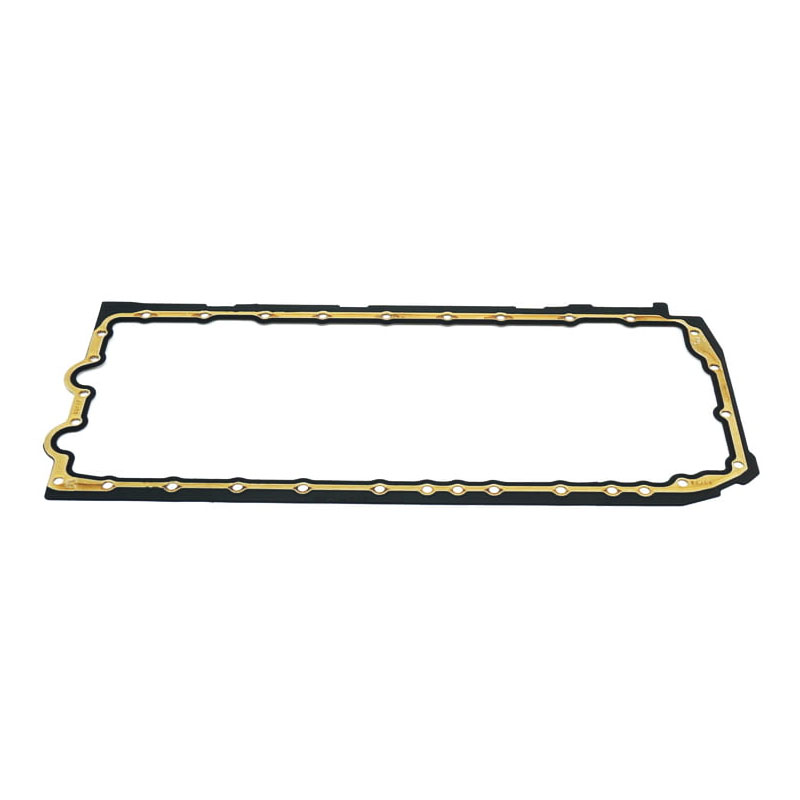

transmission shaft seal

There are different types of seals based on the specific application and design requirements. For example, lip seals feature a flexible lip that contacts the shaft, creating a hydrodynamic seal that provides excellent leak-tightness. Another type, known as O-rings, are circular seals that can be used in static or dynamic applications, offering versatility in various transmission designs. Understanding the specific requirements of your transmission system is vital in choosing the appropriate seal type.

Signs of Seal Failure

Recognizing the signs of transmission shaft seal failure early can save time and money in repairs. Common symptoms include fluid leaks around the transmission area, unusual noises from the transmission while in operation, or deteriorated performance in gear shifting. Additionally, if you notice an accumulation of dirt and grime around the seal areas, it may indicate that the seals are no longer functioning effectively. Regular inspections of the seals can help detect these issues early, allowing for timely replacements to avoid extensive damage.

Maintenance and Replacement

Proper maintenance of transmission shaft seals is crucial for their longevity and performance. Regularly checking for signs of wear, performing fluid level checks, and replacing fluids according to manufacturer recommendations can extend the life of these seals. When replacing seals, it’s important to ensure that the correct seal type and size are chosen. Professional assistance is often recommended for this process, as improper installation can lead to further complications.

In conclusion, transmission shaft seals are vital components in ensuring the smooth and efficient operation of transmission systems. Their role in preventing leaks and safeguarding against contaminants cannot be overstated. Being proactive in understanding their functionality, recognizing the signs of failure, and maintaining these seals will contribute significantly to the longevity and performance of your machinery. Whether in automotive applications or industrial equipment, prioritizing the care of transmission shaft seals is a sound investment for any operation.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories