Understanding the Importance of Trailer Bearings and Seals for Optimal Performance and Safety

Understanding Trailer Bearings and Seals Key Components for Safe Towing

When it comes to towing trailers, whether for recreational purposes, transport, or work, the importance of reliable trailer components cannot be overstated. Among these, trailer bearings and seals play a crucial role in ensuring smooth operation and safety. This article explores what trailer bearings and seals are, their functions, maintenance tips, and why they are essential for any trailer owner.

What Are Trailer Bearings?

Trailer bearings are small, round components that facilitate the smooth rotation of the trailer wheels around the axle. They consist of a series of metal balls or rollers housed within a raceway. As the wheel rotates, the bearings reduce friction between the wheel and axle, allowing for efficient and smooth movement. Properly functioning bearings help to improve the performance of the trailer, enhance fuel efficiency, and prolong the life of the tires and the axle.

There are generally two types of bearings used in trailers standard bearing and disc bearing. Standard bearings are typically found in older trailer designs, while disc bearings are more common in modern trailers due to their superior load-bearing capabilities. Regardless of the type, all trailer bearings require proper lubrication to function optimally.

The Role of Seals

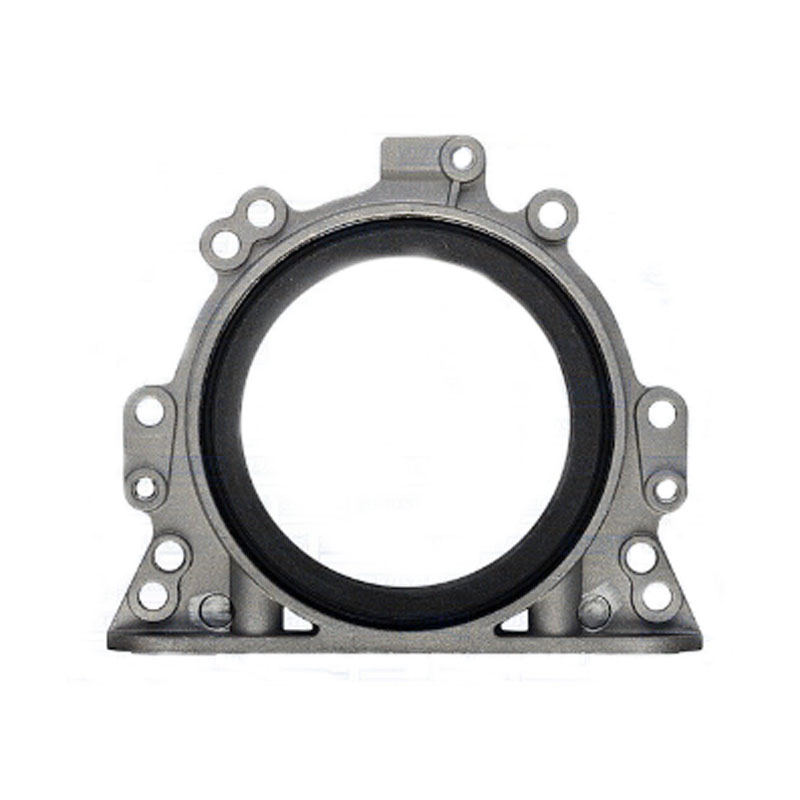

Seals are crucial components that work hand-in-hand with trailer bearings. Their primary role is to keep lubricant in and contaminants like dirt, water, and debris out of the bearing assembly. Seal failures can lead to contamination of the bearings, which can cause them to wear prematurely and potentially result in failure.

There are various types of seals, including lip seals and double-lip seals. Lip seals provide an effective barrier against contaminants but may require more frequent inspection. Double-lip seals offer better protection and are often preferred for heavier-duty applications.

trailer bearings and seals

Importance of Maintenance

Maintaining trailer bearings and seals is essential for safety and performance. Regular maintenance involves checking bearing condition, repacking bearings with grease, and inspecting seals for wear or damage. Here are some vital maintenance tips

1. Regular Inspection Inspect bearings and seals every 1,000 miles or at least once a year, whichever comes first. Look for signs of wear, discoloration, or rust.

2. Greasing Use high-quality marine-grade grease to repack bearings. This not only ensures smooth operation but also provides added protection against water intrusion.

3. Seal Checks Inspect seals for tears, cracks, or signs of wear. A damaged seal can lead to bearing failure, resulting in costly repairs or even accidents.

4. Environmental Considerations If the trailer is often exposed to harsh environments, such as saltwater or extreme weather conditions, consider upgrading to premium seals that offer better protection.

Conclusion

Understanding the importance of trailer bearings and seals is essential for any trailer owner. Proper maintenance practices can significantly extend the lifespan of these components, enhance the safety of towing, and improve overall performance. By investing time in regular inspection and maintenance, you can save yourself from unexpected breakdowns and ensure that your trailer is ready for the road. Whether you are towing a boat, camper, or heavy equipment, reliable trailer bearings and seals are fundamental for a successful and safe towing experience. Remember, a well-maintained trailer not only protects your investment but also guarantees your peace of mind on the road.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories