Understanding the Importance of Lip Seal Rings in Mechanical Applications and Their Functionality

Understanding Lip Seal Rings An Essential Component in Mechanical Systems

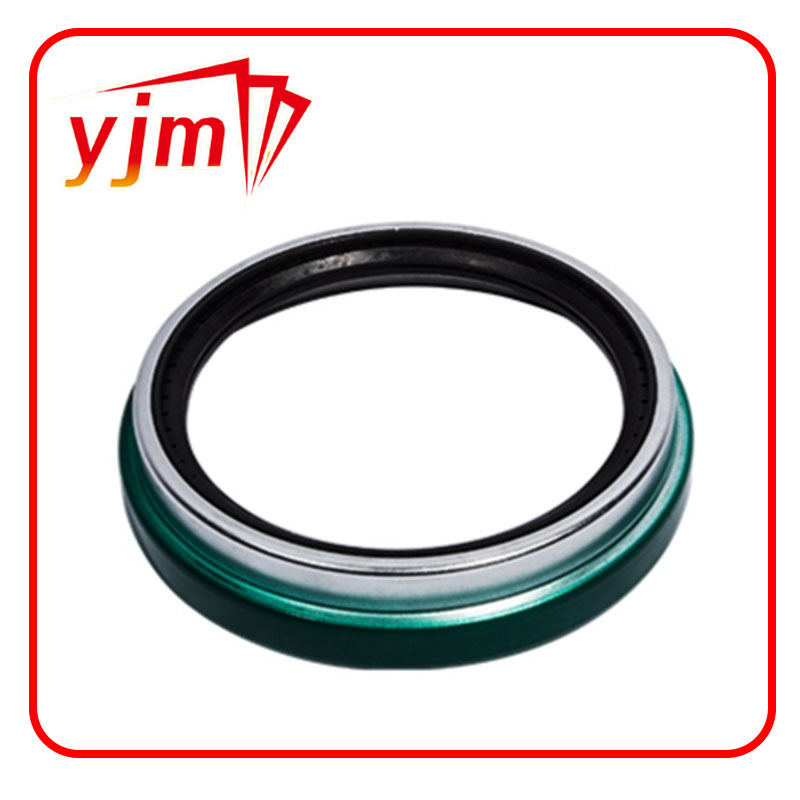

Lip seal rings are critical components used in various mechanical systems, playing a vital role in preventing fluid leakage and protecting internal parts from contaminants. These seals are often found in an array of applications, from automotive engines to industrial machinery, due to their effectiveness and versatility.

What is a Lip Seal Ring?

A lip seal ring, often referred to simply as a lip seal or oil seal, consists of a flexible lip that fits snugly against a rotating shaft or a stationary surface. Typically made from elastomers such as nitrile rubber or fluorocarbon, these materials provide excellent resilience and durability under various operating conditions. The design of the lip creates a hydrodynamic seal that minimizes friction and wear while maintaining a tight barrier against oil, grease, or other fluids.

How Lip Seal Rings Work

The operation of a lip seal ring is based on its unique geometry. When the shaft rotates, the lip makes contact with the surface, creating a narrow gap that prevents the escape of fluids. The elastic properties of the seal material allow it to conform to the shaft's surface, compensating for any irregularities and ensuring a tight fit.

Lip seals can be designed for both static and dynamic applications. In static applications, such as holding lubricants in place, the seal remains stationary while ensuring that no fluid escapes. In dynamic applications, like those found in rotating machinery, the seal must accommodate the constant movement while still performing its sealing function effectively.

Applications of Lip Seal Rings

lip seal ring

Lip seal rings find applications across various industries due to their robust sealing capabilities. In the automotive industry, they are commonly used in engines, transmissions, and differentials to prevent oil leaks and protect against dirt and moisture intrusion. In industrial contexts, lip seals are often found in pumps, gearboxes, and hydraulic systems, where their ability to withstand high pressures and temperatures is essential.

Additionally, lip seals are utilized in consumer products, such as household appliances and electronic devices, where they help to extend the lifespan of components by preventing fluid ingress.

Benefits of Lip Seal Rings

The benefits of using lip seal rings are numerous. Firstly, they significantly reduce the potential for leaks, thereby improving the efficiency and reliability of the machinery they protect. This is particularly important in applications where fluid loss could lead to catastrophic failures or environmental hazards.

Moreover, lip seal rings can operate effectively under a wide range of temperatures and pressures, making them suitable for diverse applications. Their design allows for easy installation and replacement, which is particularly valuable in maintenance scenarios.

In terms of cost-effectiveness, lip seals generally represent a lower initial investment compared to other sealing solutions, while providing exceptional longevity and reliability.

Conclusion

In conclusion, lip seal rings are indispensable components in modern mechanical systems. Their ability to prevent fluid leakage and protect critical machinery from contaminants makes them an essential part of various industries. As technology continues to evolve, the materials and designs of lip seals will also advance, further enhancing their performance and application range. Understanding lip seal rings' function and importance can help engineers and professionals make informed decisions for their projects, ensuring optimal operation and longevity of equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories