Understanding the Importance of Inboard Strut Bearings in Vehicle Performance and Safety

Understanding Inboard Strut Bearings Function and Importance

In the world of mechanical engineering and automotive design, components such as inboard strut bearings play a crucial role in ensuring vehicle stability, handling, and overall performance. While often overlooked, these small yet vital parts contribute significantly to the functionality of many modern vehicles, particularly those with independent suspension systems.

What is an Inboard Strut Bearing?

An inboard strut bearing is a type of bearing that is positioned at the top of a vehicle's strut assembly, connecting the strut to the vehicle's chassis. This component serves as a pivot point, allowing for rotational movement as the suspension system compresses and extends while the vehicle is in motion. Inboard strut bearings are typically made from durable materials, including metal and high-quality plastics, designed to withstand the rigors of daily use and the varying conditions of road environments.

The Function of Inboard Strut Bearings

The primary function of inboard strut bearings is to facilitate smooth rotation of the strut during suspension travel. When the vehicle encounters bumps, turns, or uneven surfaces, the strut must move in a way that absorbs shocks and maintains tire contact with the road. The inboard strut bearing allows for this movement while minimizing friction, which can lead to wear over time.

Moreover, these bearings help to align the strut assembly with the other components of the suspension system, ensuring proper steering and stability. They effectively reduce the transmission of vibrations and noise from the road to the vehicle's cabin, contributing to a smoother ride.

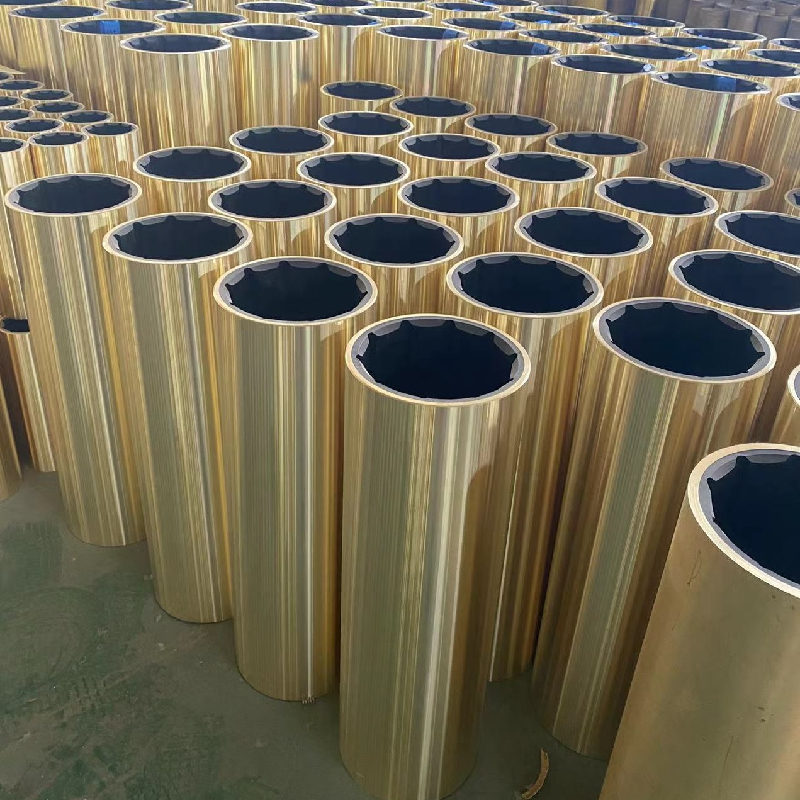

inboard strut bearing

Common Issues and Maintenance

Like any mechanical component, inboard strut bearings can experience wear and tear over time. Common symptoms of a failing bearing include a clunking noise when going over bumps, excessive vibration, and a noticeable decrease in steering responsiveness. If left unaddressed, a damaged inboard strut bearing can lead to uneven tire wear and pose safety risks during driving.

Regular maintenance and inspections are crucial to ensuring the longevity of inboard strut bearings. Mechanics usually recommend checking these components during routine vehicle inspections, especially when replacing struts or suspension components. Indicators of wear, such as play or grinding noises when turning, should prompt immediate attention to prevent further damage.

The Importance of Quality Bearings

When it comes to inboard strut bearings, quality matters. Substandard bearings can fail prematurely or not perform optimally, leading to a range of issues for the vehicle. High-quality inboard strut bearings are engineered to meet the specific demands of the vehicle and often come with warranties to assure customers of their durability. Investing in quality replacement parts can lead to better vehicle performance, greater safety, and reduced long-term maintenance costs.

Conclusion

Inboard strut bearings are integral to the performance and safety of modern vehicles. Understanding their function and the signs of wear can empower vehicle owners to take proactive measures to maintain their suspension systems. By prioritizing high-quality components and regular maintenance, drivers can ensure a smooth, comfortable, and safe driving experience. As the automotive industry continues to evolve, recognizing and valuing the significance of these often-overlooked components will remain essential for both manufacturers and consumers alike.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories