Understanding Mechanical Shaft Seals and Their Importance in Industrial Applications and Equipment Efficiency

Mechanical Shaft Seals Functionality and Importance in Engineering

Mechanical shaft seals play a crucial role in various industrial applications where rotating shafts are prevalent. They are essential components designed to prevent the leakage of fluids, whether gaseous or liquid, along the shaft and ensure the integrity of machinery. In this article, we will explore the functionality, types, advantages, and importance of mechanical shaft seals in engineering.

What Are Mechanical Shaft Seals?

Mechanical shaft seals are devices used to maintain the sealing integrity of rotating shafts in machinery. They typically consist of two main components the rotating part, which is mounted on the shaft, and the stationary part, which is secured to the housing. The contact between these two surfaces creates a sealing effect that minimizes or prevents leakage of fluids. This sealing mechanism can be employed in various applications, including pumps, motors, turbines, and compressors.

Types of Mechanical Shaft Seals

There are various types of mechanical shaft seals, each tailored for specific applications and environmental conditions. Some of the most common types include

1. Lip Seals These seals feature a flexible lip that adheres to the shaft surface. They are highly effective in sealing against low-pressure fluids and are widely used in automotive applications.

2. Rotary Seals Designed to handle higher pressures and speeds, rotary seals are often used in hydraulic applications. They provide reliable sealing and can handle a range of fluids, including oil and water.

3. Mechanical Face Seals These are often found in pump applications and consist of flat surfaces that slide against each other, creating a seal. They are suitable for high-pressure environments and can seal volatile fluids.

4. O-Ring Seals These seals are made of elastic materials, and their circular shape allows for a tight fit around the shaft. O-rings are versatile and used in numerous applications when conventional seals are insufficient.

Advantages of Mechanical Shaft Seals

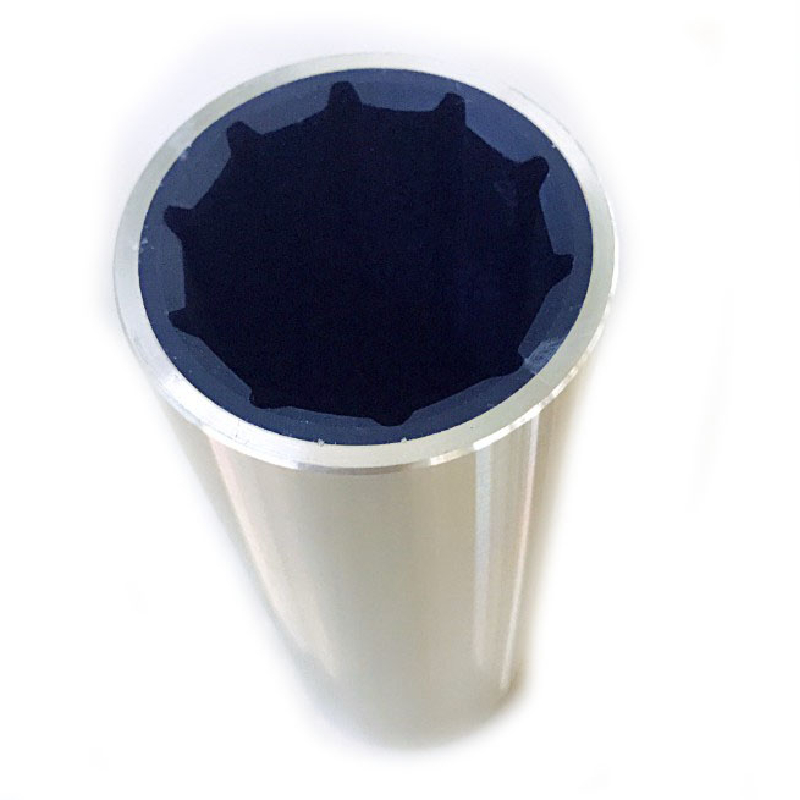

mechanical shaft seal

Using mechanical shaft seals offers numerous benefits

- Leak Prevention The primary function of these seals is to prevent fluid leaks, which can lead to costly downtimes, environmental hazards, and reduced efficiency.

- Reduced Friction High-quality mechanical seals are designed to minimize friction, which results in less wear on the shaft and prolongs the life of the machinery.

- Versatility Mechanical shaft seals can be designed for a wide variety of applications, accommodating different sizes, pressures, and temperatures. They can handle both low-viscosity fluids and abrasive materials.

- Maintenance Friendly Many mechanical shaft seals are designed for easy installation and maintenance, reducing the time and costs involved in service operations.

Importance of Mechanical Shaft Seals in Engineering

The significance of mechanical shaft seals in engineering cannot be overstated. They are integral to the performance and reliability of machinery across various industries, including manufacturing, automotive, oil and gas, and aerospace. By preventing leaks, these seals help maintain the proper operation of machinery, ensure safety, and protect the environment from contamination.

In sectors where equipment reliability is paramount, investing in high-quality mechanical shaft seals can lead to notable improvements in performance and operational efficiency. Furthermore, as industries continue to innovate and place increased emphasis on sustainability, the role of mechanical shaft seals in reducing waste and preventing pollution becomes even more vital.

Conclusion

Mechanical shaft seals are indispensable in modern engineering, providing essential functions that ensure the reliability and efficiency of machinery. Understanding the different types and applications of these seals helps engineers make informed decisions when designing and maintaining equipment. As industries evolve, the importance of mechanical shaft seals will only grow, highlighting the need for ongoing innovation in seal technology to meet the challenges of future engineering demands.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories