types of oil seals

Types of Oil Seals A Comprehensive Guide

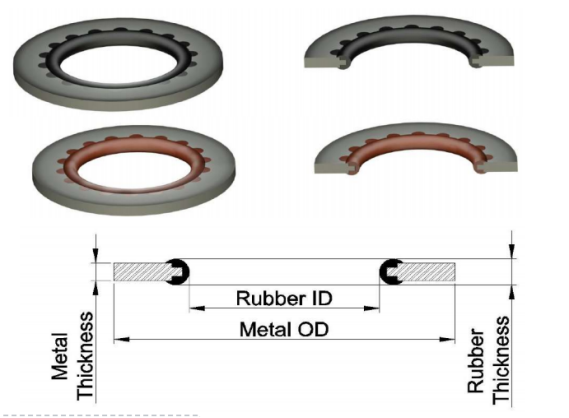

Oil seals play a crucial role in various mechanical systems, serving the vital function of preventing the leakage of fluids while protecting internal components from contaminants. These seals are widely used in automotive, aerospace, industrial machinery, and equipment applications. Understanding the different types of oil seals available can help in selecting the right one for specific applications, ensuring optimal performance and longevity.

1. Lip Seals

Lip seals, also known as radial seals, are among the most common types of oil seals. They consist of a flexible lip that contacts the shaft, forming a tight seal. The lip is usually made of elastomeric materials, providing excellent resistance to wear and the elements. Lip seals can accommodate some shaft misalignment, making them suitable for various applications such as engine components, pumps, and transmissions.

2. U-Cup Seals

U-cup seals, shaped like the letter U, provide a reliable sealing method for both static and dynamic applications. They are commonly made from rubber or polyurethane and are known for their ability to withstand high pressures. U-cup seals are often found in hydraulic systems, rod applications, and cylindrical shafts, where they provide a robust and efficient sealing solution.

3. O-Rings

O-rings are circular seals that are one of the simplest yet most effective sealing solutions. Made from various materials such as rubber, silicone, or fluoropolymer, O-rings can seal both static and dynamic applications. They are versatile and can be used in low to high-pressure conditions. Due to their simple design, O-rings are low-cost and easy to install, making them a popular choice in a range of industries.

4

. Mechanical SealsIn applications involving rotating equipment, mechanical seals are often preferred over traditional oil seals. Mechanical seals consist of two primary mating surfaces that create a seal under pressure. They are widely used in pumps, mixers, and compressors, where they provide superior sealing capability, particularly in high-speed operations. Mechanical seals offer excellent resistance against leakage and can accommodate thermal expansion, making them ideal for dynamic applications.

types of oil seals

5. Flange Seals

Flange seals, also known as gasket seals, are used to create a fluid-tight seal between two flanges. These seals are crucial in preventing fluid leakage in piping systems and are typically made from rubber, metal, or composite materials. Flange seals come in various shapes and sizes to fit different flange configurations, ensuring a secure and leak-proof joint.

6. V-Seals

V-seals are unique types of seals designed to provide excellent dirt exclusion. Shaped like a “V,” these seals are mounted on a shaft and designed to deflect contaminants away from the sealing surface. V-seals are ideal for applications where exposure to dirt and debris is a concern, such as in agricultural equipment and construction machinery.

7. Bellows Seals

Bellows seals are flexible seals that can accommodate significant axial movement and angular misalignment. These seals are often found in applications where flexibility is required, such as in certain types of pumps and valves. Made from elastomers or metal, bellows seals provide excellent resistance to various fluids and gases while maintaining flexibility.

8. Gland Seals

Gland seals are used primarily in applications involving reciprocating motion. They are designed to seal the space between a rod or piston and the housing to prevent fluid leakage. Gland seals can be made from rubber or advanced polymer materials and are especially effective in hydraulic and pneumatic systems, where they help maintain pressure and prevent loss of fluid.

Conclusion

Selecting the right type of oil seal is essential for the performance and longevity of any mechanical system. Each type of oil seal has its unique advantages and applications, making it crucial to understand their characteristics before making a choice. Proper installation and regular maintenance of oil seals can significantly reduce the risk of leaks and equipment failure, enhancing operational efficiency. For engineers and technicians, familiarity with the various types of oil seals ensures better designs, increased reliability, and improved service life of machinery and equipment. Whether for automotive applications, industrial machinery, or home appliances, the right oil seal is vital for maintaining high performance and operational integrity.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories