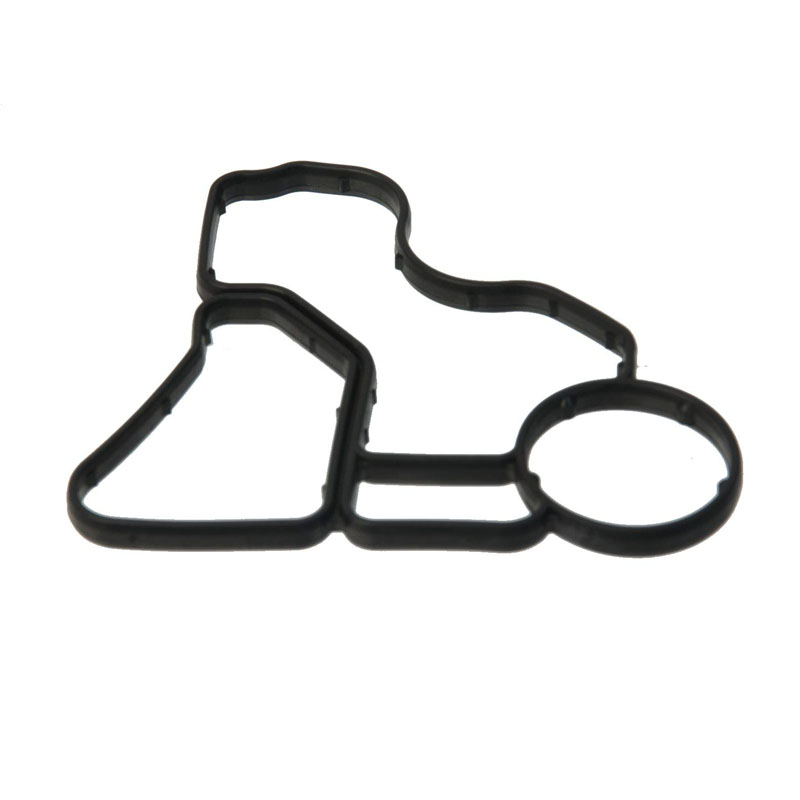

types of oil seal

Types of Oil Seals Understanding Their Importance and Applications

Oil seals, often referred to as mechanical seals or shaft seals, are crucial components in various machinery and automotive applications. Their primary function is to prevent the leakage of oil and other lubricants while keeping contaminants out of the machinery. This article explores the different types of oil seals, their designs, materials, and applications.

1. Basic Types of Oil Seals

Oil seals can be classified into a few basic types based on their design and functionality

- Single Lip Oil Seals These are the most common type, featuring a single lip that provides a sealing surface against the shaft. The lip is often spring-loaded to maintain contact with the shaft, ensuring a tight seal. Single lip oil seals are typically used in applications where only low to moderate pressure is present.

- Double Lip Oil Seals These seals have two lips for enhanced sealing performance. They are designed to retain oils and prevent external contaminants more effectively than single lip seals. Double lip oil seals are frequently used in environments where dust, dirt, and moisture may be present.

- Tandem Oil Seals Tandem arrangements consist of two oil seals placed in series. This design is particularly effective for high-pressure applications and provides an extra layer of protection against leaks.

2

. Materials UsedThe material of an oil seal plays a significant role in its effectiveness and durability. Common materials include

- Nitrile Rubber (NBR) Known for its excellent resistance to oil and other lubricants, NBR is widely used in automotive applications. It can withstand a wide temperature range and offers good wear resistance.

- Fluoroelastomer (FKM) This material is ideal for high-temperature applications and is resistant to aggressive fluids. FKM seals are typically used in more demanding environments, such as aerospace and chemical processing.

types of oil seal

- Polyurethane Offering superior abrasion resistance, polyurethane is commonly used in heavy machinery and off-road vehicles. It combines elasticity with strength, making it suitable for a variety of applications.

3. Applications of Oil Seals

Oil seals are used in an extensive range of machinery and equipment across various industries

- Automotive Industry In vehicles, oil seals are found in engine compartments, axles, and transmissions. They help maintain oil levels and protect engine components from dirt and grime.

- Industrial Machinery Oil seals are integral to pumps, compressors, and gearboxes, ensuring efficient operation by preventing lubricant loss and contamination.

- Aerospace In aerospace applications, oil seals are critical for ensuring the integrity of hydraulic systems and preventing fluid leaks at high altitudes and speeds.

4. Maintenance and Replacement

Regular maintenance and timely replacement of oil seals can prevent catastrophic failures in machinery. Signs of wear include oil leaks, unusual noises, and decreased efficiency. It is crucial to choose the right oil seal type and material for specific applications to enhance durability and performance.

Conclusion

Understanding the various types of oil seals and their applications is essential for anyone involved in machinery operation or maintenance. By selecting the appropriate seal type and maintaining it properly, one can significantly prolong the life of machinery and equipment while ensuring optimal performance. Whether it’s in an automobile, an industrial machine, or an aerospace application, the role of oil seals cannot be underestimated in achieving efficient and reliable operation.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories