Types of oil seals are crucial.

. Garter spring seals are particularly useful in heavy-duty equipment where vibration and temperature fluctuations are prevalent.

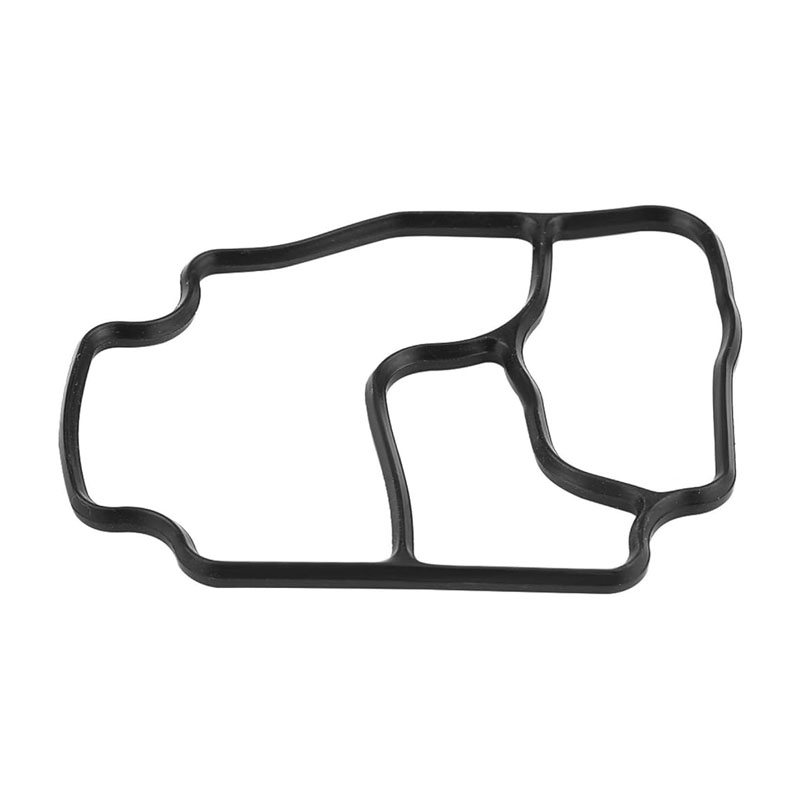

Oring seals, while not exclusively for oil, are worth mentioning due to their versatility. They are simple in design, consisting of a circular cross-section ring made from elastomeric materials. O-rings can be used in both static and dynamic applications and are often found in hydraulic and pneumatic systems.

Lastly, there are unitized seals, which combine multiple sealing elements into one assembly. These complex seals offer enhanced protection against leakage and are commonly used in automotive transmissions and industrial machinery where space is limited, and reliability is paramount.

In conclusion, the type of oil seal employed depends on the specific requirements of the machinery in question. From radial and axial lip seals to garter spring and unitized seals, each has its advantages and is tailored to handle different operational challenges. Proper selection and installation of these seals are crucial for maintaining the integrity of lubrication systems and ensuring the smooth operation and long lifespan of mechanical devices.

. Garter spring seals are particularly useful in heavy-duty equipment where vibration and temperature fluctuations are prevalent.

Oring seals, while not exclusively for oil, are worth mentioning due to their versatility. They are simple in design, consisting of a circular cross-section ring made from elastomeric materials. O-rings can be used in both static and dynamic applications and are often found in hydraulic and pneumatic systems.

Lastly, there are unitized seals, which combine multiple sealing elements into one assembly. These complex seals offer enhanced protection against leakage and are commonly used in automotive transmissions and industrial machinery where space is limited, and reliability is paramount.

In conclusion, the type of oil seal employed depends on the specific requirements of the machinery in question. From radial and axial lip seals to garter spring and unitized seals, each has its advantages and is tailored to handle different operational challenges. Proper selection and installation of these seals are crucial for maintaining the integrity of lubrication systems and ensuring the smooth operation and long lifespan of mechanical devices. -

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories