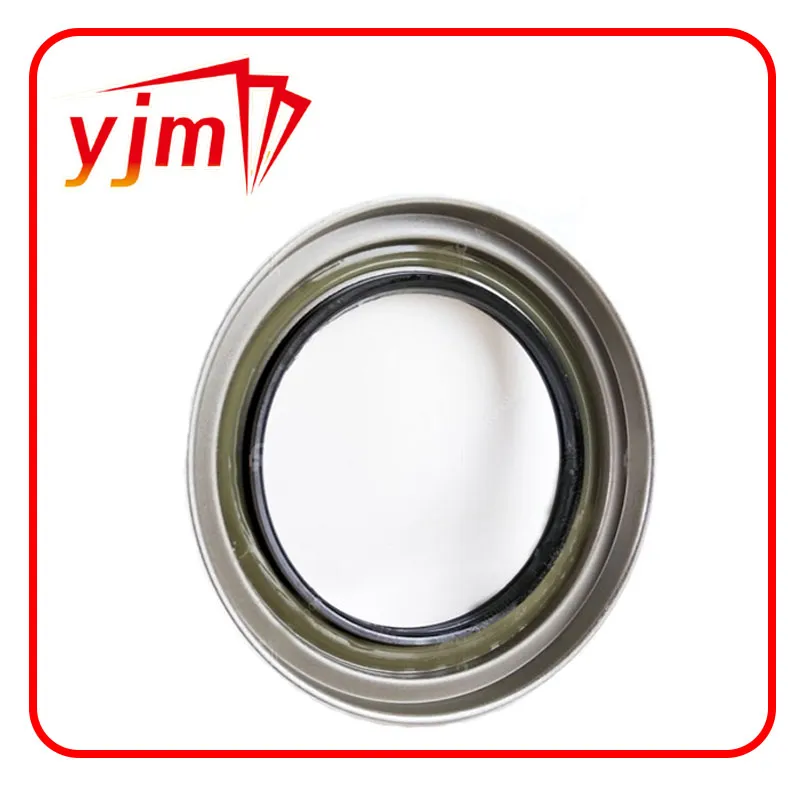

tto oil seal

Understanding TTO Oil Seals A Comprehensive Overview

TTO oil seals, also referred to as TTO (Tungsten, Titanium, and Oxygen) oil seals, are essential components widely used in various mechanical systems to prevent the leakage of fluids and contaminants. These seals play a critical role in maintaining the efficiency and integrity of machinery, whether in automotive applications, industrial equipment, or consumer appliances. This article aims to provide an in-depth understanding of TTO oil seals, their composition, applications, advantages, and maintenance.

Composition and Structure

TTO oil seals are crafted from a combination of advanced materials that closely interact to create a durable and effective sealing solution. The inclusion of tungsten and titanium in the seal's composition contributes to its robustness and resilience against harsh conditions. Tungsten provides exceptional hardness and wear resistance, while titanium enhances corrosion resistance and strength.

Typically, a TTO oil seal features several layers an elastomeric body for flexibility and sealing capability, a metal case for structural support, and sometimes a spring for improved sealing under varying pressure conditions. This multi-layer design ensures that the seal can effectively withstand extreme temperatures, pressure changes, and aggressive chemicals that often characterize certain applications.

Applications of TTO Oil Seals

TTO oil seals find application across a wide range of industries, reflecting their versatility and reliability. Here are some key areas where TTO oil seals are commonly used

1. Automotive Industry In vehicles, TTO oil seals are crucial for preventing oil leaks from engines and transmissions. These seals ensure that lubricants remain within the designated compartments, which is vital for the smooth operation of moving parts.

2. Industrial Machinery In manufacturing plants, TTO seals contribute to the performance of hydraulic systems, pumps, and motors, where the containment of hydraulic fluids is essential for operational efficiency.

3. Household Appliances Many common household devices—such as refrigerators and washing machines—rely on TTO oil seals to prevent leaks that could lead to damage and decreased performance.

tto oil seal

Advantages of TTO Oil Seals

The adoption of TTO oil seals presents numerous advantages

- Enhanced Durability The robust materials used in TTO oil seals make them resistant to wear, tear, and environmental factors, leading to longer service life compared to traditional seals.

- Temperature and Chemical Resistance TTO oil seals maintain their integrity over a wide temperature range and are resistant to many common chemicals, making them suitable for diverse applications.

- Reduced Maintenance Costs By preventing fluid leaks, TTO oil seals help in reducing maintenance costs associated with fluid loss and equipment damage. This efficiency translates to less downtime and enhanced productivity.

- Improved Performance The effective sealing provided by TTO oil seals ensures that machinery operates smoothly, leading to improved performance and energy efficiency.

Maintenance and Replacement

While TTO oil seals are designed to be durable, regular maintenance is crucial for extending their lifespan. Users should periodically inspect seals for signs of wear, oil leakage, or deformation. Prompt replacement is also essential when seals begin to show signs of decline, as ignoring these issues could lead to more significant mechanical failures.

Cleaning surrounding components and ensuring proper installation can help maintain the integrity of TTO oil seals. It’s important to follow manufacturer recommendations for installation procedures and specifications to achieve optimal performance.

Conclusion

TTO oil seals represent a significant advancement in sealing technology, combining the strength and durability of tungsten and titanium to offer superior performance in a wide array of applications. Their reliability in preventing leaks and maintaining efficiency makes them an indispensable component in various industries. By understanding their composition, applications, benefits, and maintenance needs, users can ensure the optimal performance of their machinery and equipment, ultimately leading to greater operational success. Continuous advancements in material science and sealing technology hint at even more robust solutions for the future, further solidifying the role of TTO oil seals in modern engineering.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories