Choosing Trailer Wheel Seals Based on Size for Optimal Performance

Understanding Trailer Wheel Seals by Size

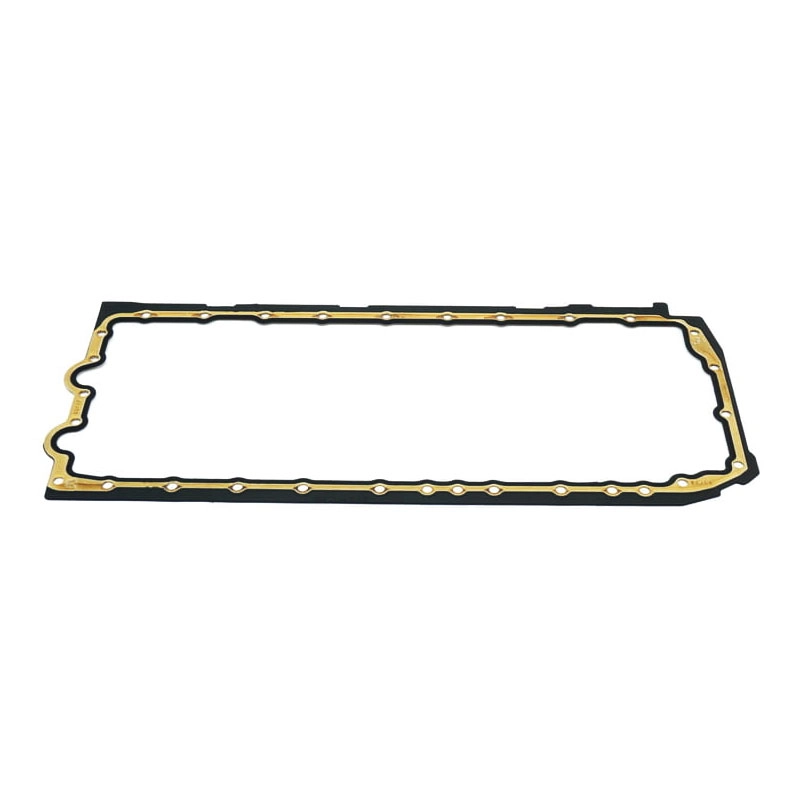

When it comes to maintaining the integrity and performance of your trailer, one of the often-overlooked components is the wheel seal. Trailer wheel seals play a crucial role in keeping the wheel bearings lubricated while preventing contaminants such as dirt, water, and debris from entering the hub assembly. A proper seal ensures that your trailer runs smoothly and enhances its longevity. In this article, we will delve into the significance of trailer wheel seals, particularly focusing on their sizes and the implications of choosing the right size for your specific application.

The Importance of Wheel Seals

Wheel seals are designed to protect the bearings and other components of the wheel hub from environmental conditions and wear. When water or dirt infiltrates the bearings, it can lead to corrosion and eventual failure, resulting in costly repairs and downtime. By sealing the bearings effectively, wheel seals ensure that the grease remains where it belongs and that the trailer operates efficiently under varying conditions.

Different Sizes of Trailer Wheel Seals

Trailer wheel seals come in various sizes, each tailored to fit specific axle types and configurations. Understanding these sizes is crucial for selecting the right seal for your trailer. The size of the seal generally corresponds to the diameter and thickness required for a particular axle model. Common seal sizes include but are not limited to the following

- 1.5-inch Seal Often employed in smaller trailers and light-duty applications, this size is a popular choice for utility trailers and lightweight cargo trailers. - 2.0-inch Seal Suitable for a wider range of applications, 2.0-inch seals are commonly found in standard utility and boat trailers, providing a robust option for moderate loads. - 2.25-inch Seal This size is often utilized in heavier trailers, including larger boat and horse trailers. It’s designed to withstand the demands of more substantial loads. - 2.625-inch Seal Typically used in commercial-grade trailers, this size is ideal for heavy-duty applications where the strain on axles and bearings is more significant.

trailer wheel seals by size

Choosing the Right Size

Choosing the correct size of trailer wheel seal is paramount. An undersized seal may not provide adequate coverage, allowing harmful elements to enter the hub, while an oversized seal might lead to difficulties in installation and could fail to create an effective barrier. To determine the appropriate size, you should check the specifications provided by the trailer manufacturer or measure the existing seal, if available.

Maintenance Tips

Maintaining your trailer wheel seals is equally important as selecting the right size. Periodically inspect the seals for any signs of wear or damage. Look for cracks, splits, or any deformation that may indicate a failing seal. If any such issues are identified, replacing the seal promptly can prevent more severe damage to the wheel bearings and other components.

Additionally, during routine maintenance of your trailer, it is advisable to replace the wheel seals whenever you re-pack or replace the wheel bearings, as the seals can degrade over time due to heat and friction.

Conclusion

In conclusion, trailer wheel seals play a critical role in the upkeep of your trailer, and understanding the various sizes available is essential for optimal performance. By selecting the right size and ensuring regular maintenance, you can prolong the life of your trailer's wheel bearings and enjoy safe and reliable travels. Always consult your trailer’s manual or seek advice from a professional if you are uncertain about the correct size for your trailer’s application. Taking these steps will ensure your trailer remains in excellent condition for years to come.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories