Understanding Trailer Wheel Bearing Grease Seals for Optimal Performance and Maintenance

Understanding Trailer Wheel Bearing Grease Seals Importance and Maintenance

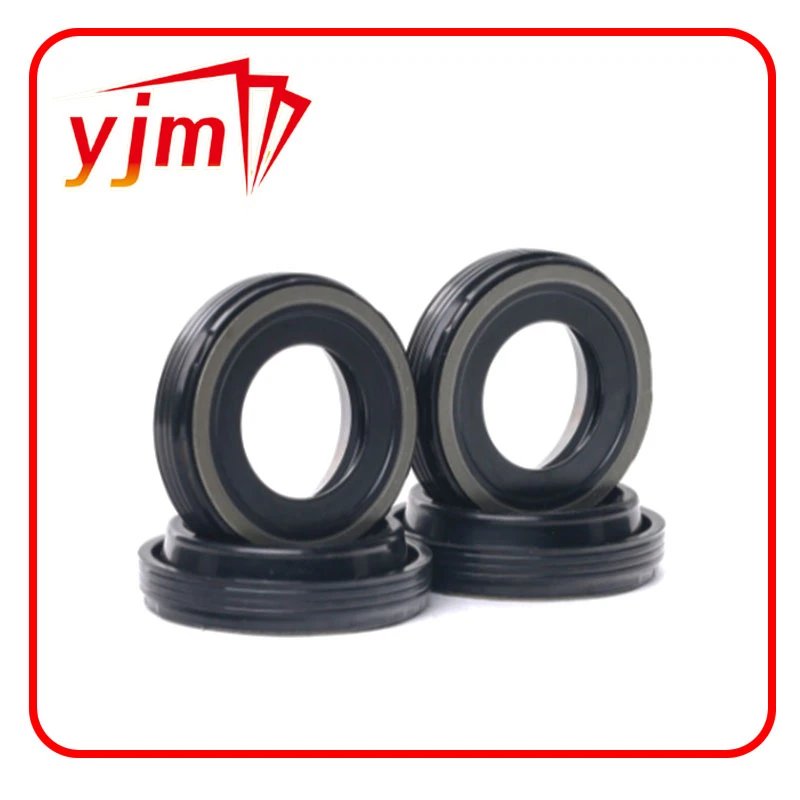

When it comes to maintaining the performance and safety of your trailer, one often overlooked component is the wheel bearing grease seals. These seals play a crucial role in ensuring that your trailer operates smoothly and efficiently by protecting the wheel bearings from dirt, water, and other contaminants. Understanding the importance of these seals and how to properly maintain them can save you from costly repairs and enhance your overall towing experience.

What Are Wheel Bearing Grease Seals?

Wheel bearing grease seals are designed to keep the lubricant in and the contaminants out of the wheel bearing assembly. Positioned at the wheel hub, these rubber or silicone seals act as a barrier against moisture, debris, and other elements that could compromise the integrity of the bearings. They also help prevent grease from leaking out, ensuring that the bearings remain properly lubricated during operation.

Why Are They Important?

The function of wheel bearing grease seals is vital for several reasons

1. Protection Against Contaminants Trailers often travel through muddy, dirty, or wet conditions, which can lead to the entry of harmful debris into the wheel bearing assembly. Grease seals create a protective barrier that keeps these contaminants out, thus prolonging the life of the bearings.

2. Grease Retention Proper lubrication is essential for the smooth operation of wheel bearings. If grease leaks out due to a damaged or worn seal, the bearings can run dry, leading to increased friction, overheating, and eventual failure.

3. Enhanced Safety Compromised wheel bearings can result in serious safety hazards while towing. A wheel bearing failure can lead to a loss of control of the trailer, posing risks not only to the vehicle but also to other road users.

trailer wheel bearing grease seals

Maintenance Tips for Wheel Bearing Grease Seals

To ensure that your trailer's wheel bearing grease seals remain effective, regular maintenance is critical. Here are some tips to keep them in good condition

1. Regular Inspections Periodically check the seals for signs of wear, cracks, or damage. If you notice any abnormalities, consider replacing the seals before they lead to more serious issues.

2. Proper Grease Application Use high-quality grease that is specifically designed for trailer wheel bearings. Ensure that the bearings are adequately packed with grease during maintenance to minimize the risk of leaks.

3. Monitor Performance Pay attention to how your trailer operates while towing. Unusual noises, heat, or vibrations can indicate that your wheel bearings or grease seals might be failing.

4. Replace When Necessary If you notice a significant loss of grease or if the seals become damaged, replace them as soon as possible. It's a relatively simple and cost-effective maintenance task that can prevent more extensive damage.

Conclusion

In summary, wheel bearing grease seals are a critical component of your trailer's wheel assembly. They protect against contaminants, help retain lubrication, and contribute to the safety and efficiency of towing. Regular inspections and maintenance are essential to ensure these seals are functioning properly. By investing a little time and attention into this aspect of your trailer’s upkeep, you can enhance its performance and longevity, making your towing experience safer and more enjoyable.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories