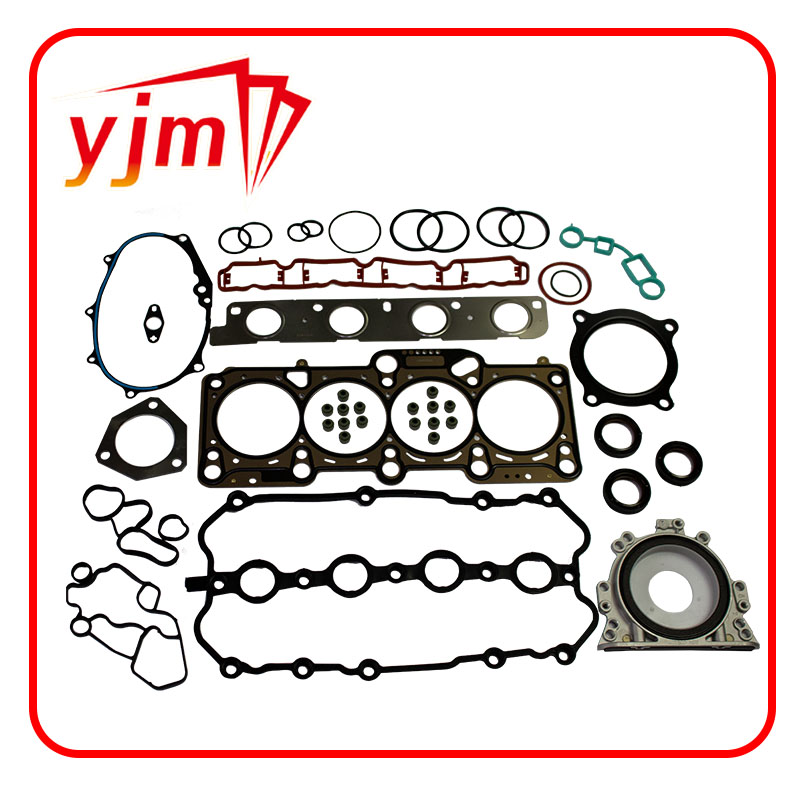

trailer bearing seal

Understanding Trailer Bearing Seals Importance and Maintenance

When it comes to maintaining your trailer, one of the often-overlooked components is the trailer bearing seal. This vital part ensures that the bearings within the wheel hubs operate efficiently, which is crucial for the overall performance and longevity of your trailer. In this article, we will delve into the purpose of trailer bearing seals, their types, common issues, and maintenance tips to keep them in optimal condition.

What is a Trailer Bearing Seal?

A trailer bearing seal is a protective component that prevents the ingress of dirt, water, and debris into the wheel hub where the bearings reside. It also retains the necessary lubrication within the hub, ensuring that the bearings function smoothly and efficiently. During operation, bearings experience significant friction and heat, which can lead to wear and tear. A good seal ensures that the necessary grease or oil is maintained and that external contaminants are kept at bay.

Types of Trailer Bearing Seals

There are several types of trailer bearing seals, each designed for specific applications

1. Single Lip Seals These are the most common type and provide adequate protection for standard applications. They consist of a single lip that presses against the bearing surface to keep lubrication in and contaminants out.

2. Double Lip Seals Offering enhanced protection, double lip seals feature two contact surfaces. This design is particularly useful for trailers that operate in harsh environments where exposure to water and debris is a concern.

3. Internal Seals Used primarily in specialized trailers, internal seals are housed within the bearing units. They are especially beneficial for high-speed applications.

Signs of Seal Wear or Damage

trailer bearing seal

Regular inspection of your trailer bearing seals is crucial. Some signs that a seal may be failing include

- Excessive Noise If the trailer makes unusual noises while in motion, it may indicate bearing failure caused by seal damage. - Grease Leakage A noticeable loss of grease from the wheel hub is a clear sign that the seal has worn out and is no longer effective.

- Rust or Corrosion Inspect for signs of rust on bearings or metal surfaces, which can indicate that water has entered due to a compromised seal.

Maintenance Tips

Maintaining your trailer bearing seals can extend their lifespan and enhance the performance of your trailer. Here are some essential maintenance tips

- Routine Inspections Regularly inspect the seals for wear and tear. Make this part of your routine maintenance checks, especially before long trips.

- Re-greasing Ensure that the bearings are properly greased. Follow manufacturer guidelines for the type and amount of grease to use.

- Professional Servicing If you notice any signs of wear or damage, it’s advisable to have the seals and bearings checked by a professional. Don't hesitate to replace worn seals promptly to avoid further issues.

Conclusion

Trailer bearing seals play a critical role in ensuring the smooth operation of your trailer. Understanding their importance, types, and maintenance can save you time, money, and hassle in the long run. By keeping your bearings well-sealed and lubricated, you can ensure a safe and smooth journey, whether you’re hauling goods, camping, or enjoying recreational activities. Remember, proactive maintenance is key to a dependable trailer experience.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories