Trailer Hub Bearings and Seals - High-Quality Replacement Parts

Understanding Trailer Hub Bearings and Seals

Trailer hub bearings and seals are crucial components in the functionality and safety of any trailer. These parts work together to facilitate smooth wheel rotation while protecting against environmental contaminants. A thorough understanding of their role, maintenance, and replacement is essential for ensuring optimal trailer performance.

The Role of Hub Bearings

Hub bearings are specialized components that allow the wheel to rotate smoothly around the axle. They consist of a series of metal balls or rollers that reduce friction between the wheel and axle, ensuring efficient motion. Properly functioning bearings are vital for maintaining proper wheel alignment and reducing wear on tires, which can lead to costly replacements.

Bearings come in various designs, but the most common types found in trailers are tapered roller bearings and ball bearings. Tapered roller bearings are particularly popular due to their ability to handle both radial and axial loads. Regular maintenance, including lubrication and inspection, is necessary to prevent premature wear and failure.

The Importance of Seals

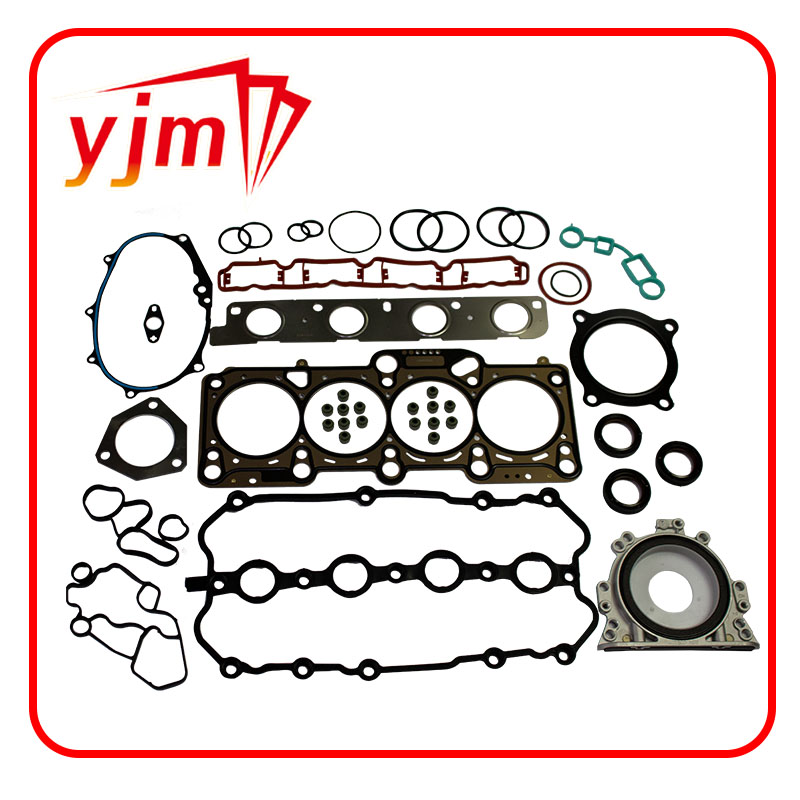

trailer hub bearings and seals

Seals are often overlooked but play an equally important role in the longevity of trailer hub bearings. They protect the bearings from dirt, water, and other contaminants that could lead to rust and failure. A well-functioning seal ensures that the lubricant remains in place, preventing metal-on-metal contact that can cause significant damage.

There are various types of seals, including rubber and oil seals. It is essential to select the right type depending on the specific environment in which the trailer operates. For instance, trailers subjected to wet or muddy conditions require seals that can withstand harsher environments.

Maintenance and Replacement

Regular inspection of hub bearings and seals is crucial for identifying any wear or damage before it leads to bigger issues. Common signs of bearing failure include unusual noises, excessive heat, or noticeable play in the wheel. Similarly, damaged seals may show signs of grease leakage or cracks.

For optimal performance, it's recommended to inspect and maintain hub bearings at least once a year, or more frequently if the trailer is used heavily. If any damage is identified, replacing the bearings and seals promptly is vital, as it ensures safety on the road and extends the life of the trailer.

In conclusion, trailer hub bearings and seals are fundamental to the safety and efficiency of trailer operations. By understanding their functions, regularly inspecting them, and replacing worn components, trailer owners can enjoy a smoother, safer journey while extending the lifespan of their equipment.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories