Tides Shaft Seal - Reliable Sealing Solutions for Marine and Industrial Applications

Understanding Tides Shaft Seals An Essential Component in Marine Engineering

In the realm of marine engineering, the effectiveness of machinery is pivotal to ensuring safety and efficiency at sea. One critical component that often goes unnoticed but plays an essential role in maintaining operational effectiveness is the shaft seal, particularly in the context of tidal energy systems. Tides shaft seals are specifically designed to prevent seawater from intruding into the internal machinery of vessels and tidal turbines, thus safeguarding the mechanical integrity and longevity of these systems.

A shaft seal serves as a barrier between the water environment and the internal components of marine machinery. In tidal energy applications, where turbines harness the kinetic energy of moving water, maintaining an impermeable seal is crucial. The forces exerted by the tidal movements can be significant, making the design and reliability of these seals paramount. Any compromise in the seal can lead to water ingress, which may damage the machinery and lead to costly repairs or failures.

The design of a tides shaft seal must accommodate various operational conditions. Tidal flows can be unpredictable, with changes in pressure and velocity affecting the seal's performance. For this reason, materials used in the construction of shaft seals are selected based on their durability, flexibility, and resistance to corrosion. Common materials include elastomers, metals, and composites that can withstand harsh marine environments.

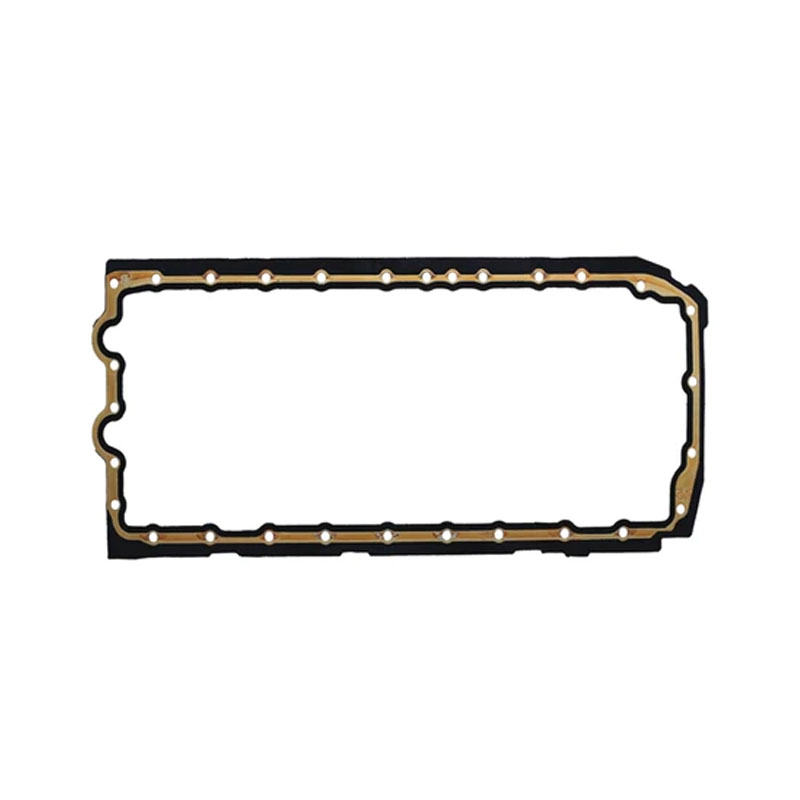

tides shaft seal

Moreover, the installation and maintenance of tides shaft seals are critical to their functionality. Improper installation can lead to premature failure, while neglecting regular maintenance checks may result in undetected wear and tear. Engineering teams are tasked with not only ensuring that these seals are appropriately installed but also developing maintenance schedules that account for the unique challenges posed by tidal operations. This includes inspecting seals for signs of degradation, replacing worn components, and verifying that the seals remain watertight under varying operational pressures.

In addition to mechanical reliability, environmental considerations are increasingly influencing the design and implementation of tidal shaft seals. With growing concerns about marine ecosystems and pollution, manufacturers are focusing on creating seals that not only perform effectively but also minimize their ecological footprint. This involves using sustainable materials and designs that reduce the likelihood of material failure, thereby decreasing the chances of environmental contamination.

In conclusion, tides shaft seals play a vital role in marine engineering, particularly in the context of tidal energy systems. Their ability to prevent water ingress is essential for protecting machinery from damage and ensuring smooth operational performance. As technology advances and environmental considerations become more prominent, the design and materials used in these seals will continue to evolve, leading to more reliable and sustainable solutions. By prioritizing the integrity of shaft seals, engineers can enhance the efficiency and longevity of marine machinery, ultimately contributing to the broader goals of renewable energy and environmental stewardship.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories