The front pump seal is crucial.

. Proper installation techniques are equally important; misalignment or excessive tightening can cause premature seal failure. Additionally, the compatibility of the seal with the lubricant or cooling system should be considered to avoid degradation of the seal material.

Environmental considerations also drive the development of front pump seals. Spillage not only wastes valuable resources but can also pose significant environmental risks. A single leaky seal can result in thousands of gallons of pollutants being released into the ecosystem over its lifetime. Therefore, designing seals that minimize emissions supports sustainable industrial practices and aligns with increasingly stringent environmental regulations.

In conclusion, the front pump seal is a small but mighty component within industrial pump systems. Its ability to maintain a reliable barrier between the process fluid and the outside world is crucial for safe, efficient, and eco-friendly operations. As technology advances, so too will the designs of these vital components, ensuring that they continue to protect our systems and environment for years to come.

. Proper installation techniques are equally important; misalignment or excessive tightening can cause premature seal failure. Additionally, the compatibility of the seal with the lubricant or cooling system should be considered to avoid degradation of the seal material.

Environmental considerations also drive the development of front pump seals. Spillage not only wastes valuable resources but can also pose significant environmental risks. A single leaky seal can result in thousands of gallons of pollutants being released into the ecosystem over its lifetime. Therefore, designing seals that minimize emissions supports sustainable industrial practices and aligns with increasingly stringent environmental regulations.

In conclusion, the front pump seal is a small but mighty component within industrial pump systems. Its ability to maintain a reliable barrier between the process fluid and the outside world is crucial for safe, efficient, and eco-friendly operations. As technology advances, so too will the designs of these vital components, ensuring that they continue to protect our systems and environment for years to come. -

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

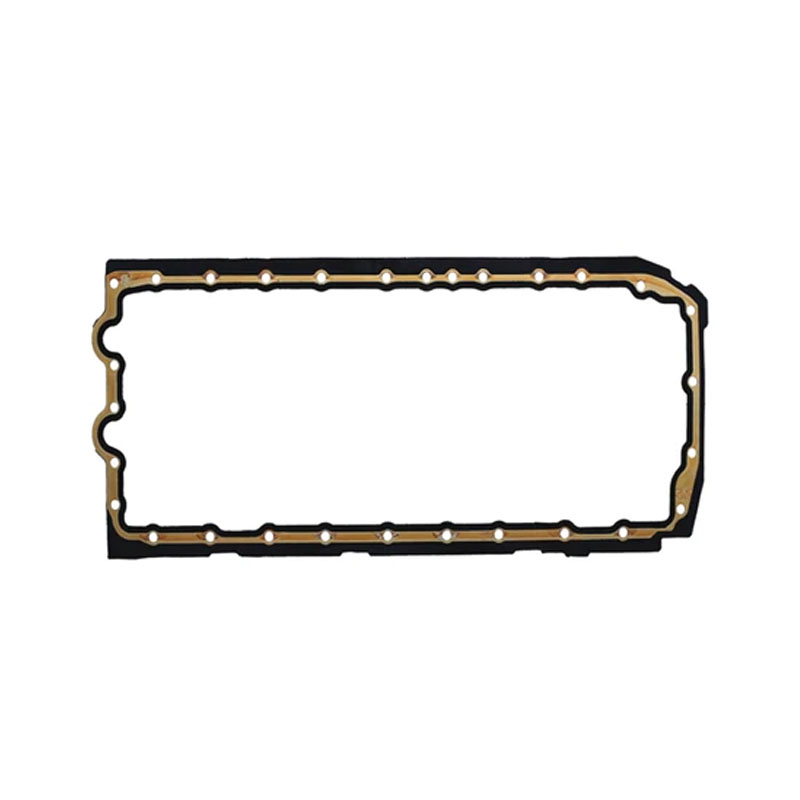

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories