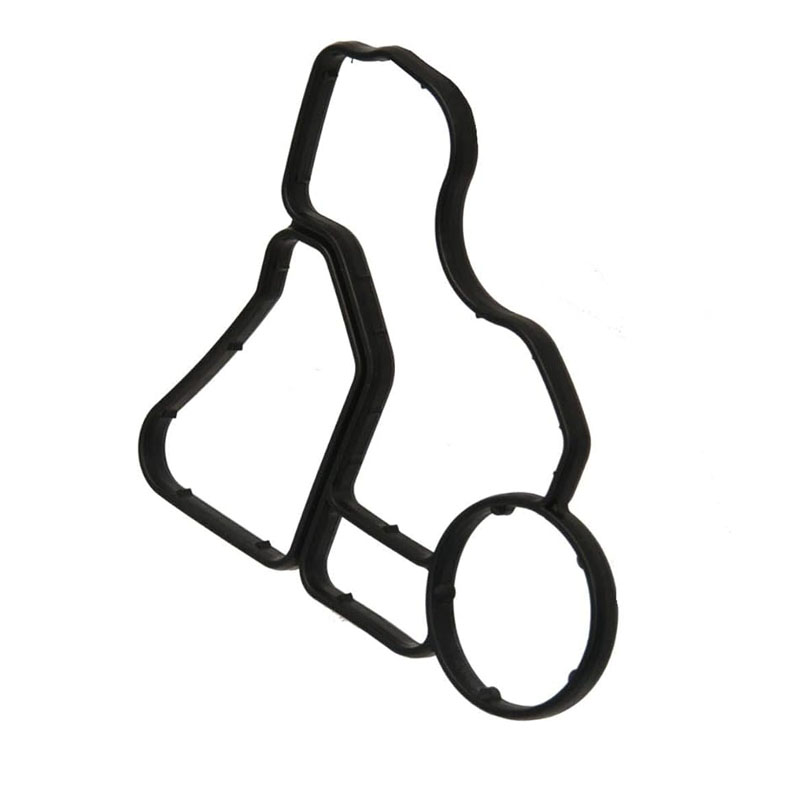

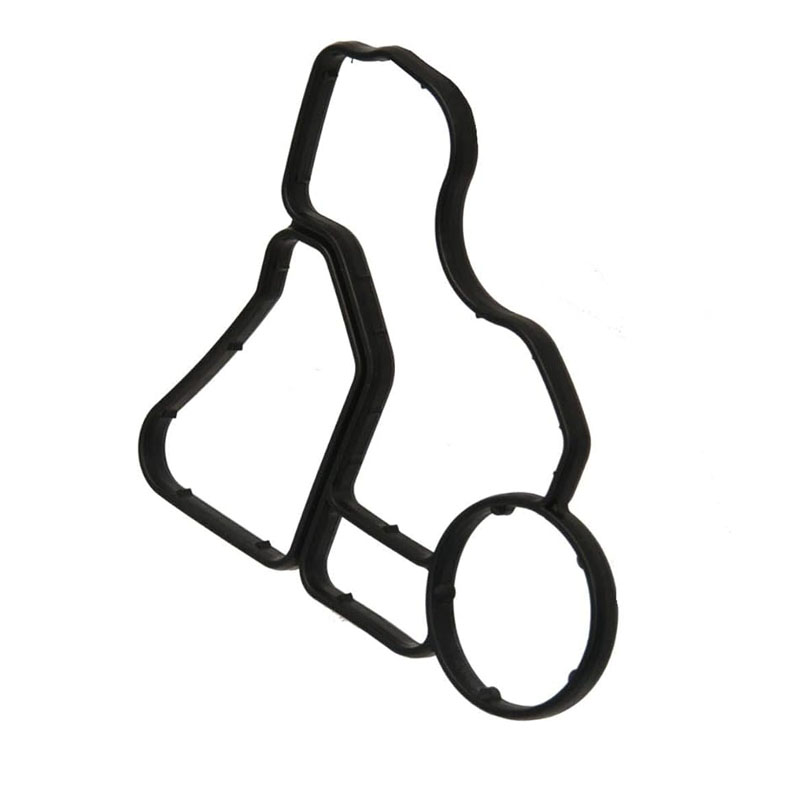

Telescopic Oil Seal Advanced Protection for Smooth Mechanism Operation

This lip, combined with the elasticity of the seal material, ensures a tight grip on the shaft, minimizing wear and tear while preventing fluid loss This lip, combined with the elasticity of the seal material, ensures a tight grip on the shaft, minimizing wear and tear while preventing fluid loss

This lip, combined with the elasticity of the seal material, ensures a tight grip on the shaft, minimizing wear and tear while preventing fluid loss This lip, combined with the elasticity of the seal material, ensures a tight grip on the shaft, minimizing wear and tear while preventing fluid loss telescopic oil seal. Moreover, the unique design enables the seal to compensate for minor misalignments, surface irregularities, and thermal expansion, thus reducing the risk of premature failure.

Beyond their functional benefits, telescopic oil seals contribute significantly to environmental sustainability by preventing oil spills and reducing the need for frequent lubrication. They also have a direct impact on energy efficiency, as well-maintained seals minimize friction, leading to reduced power consumption.

In conclusion, telescopic oil seals are indispensable elements in modern machinery, ensuring not only optimal performance but also environmental protection and energy conservation. Their significance extends beyond their humble size, as they safeguard the integrity of complex systems and contribute to the overall reliability and longevity of the equipment they serve. As technology continues to advance, so too do the materials and designs of telescopic oil seals, promising even greater efficiency and resilience in the future.

telescopic oil seal. Moreover, the unique design enables the seal to compensate for minor misalignments, surface irregularities, and thermal expansion, thus reducing the risk of premature failure.

Beyond their functional benefits, telescopic oil seals contribute significantly to environmental sustainability by preventing oil spills and reducing the need for frequent lubrication. They also have a direct impact on energy efficiency, as well-maintained seals minimize friction, leading to reduced power consumption.

In conclusion, telescopic oil seals are indispensable elements in modern machinery, ensuring not only optimal performance but also environmental protection and energy conservation. Their significance extends beyond their humble size, as they safeguard the integrity of complex systems and contribute to the overall reliability and longevity of the equipment they serve. As technology continues to advance, so too do the materials and designs of telescopic oil seals, promising even greater efficiency and resilience in the future. -

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories