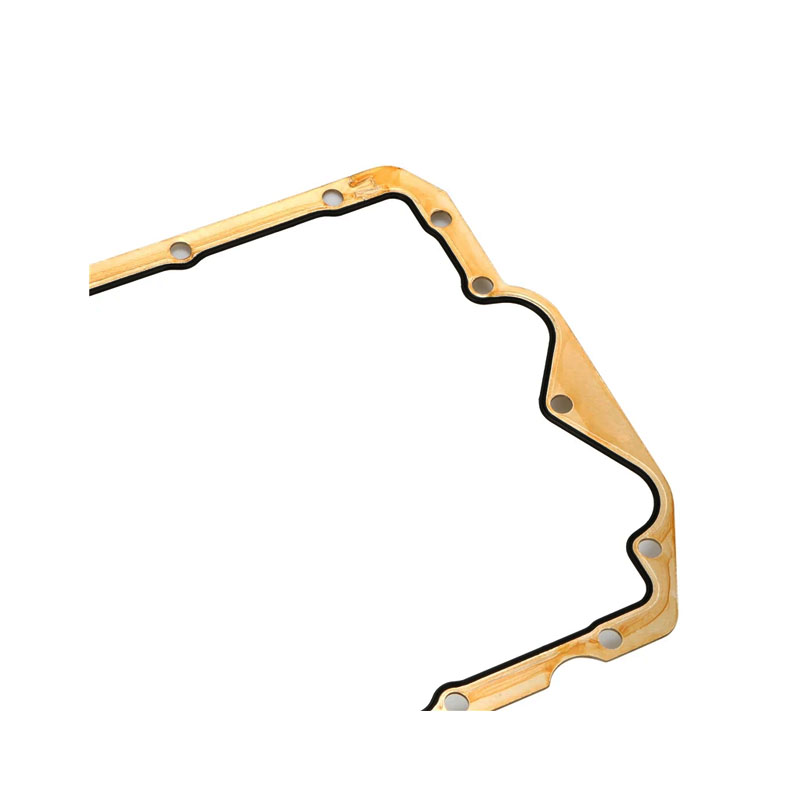

Teflon Shaft Seal

Understanding Teflon Shaft Seals Benefits and Applications

Teflon shaft seals are essential components in various mechanical systems, providing a reliable barrier against fluid leaks. Made from polytetrafluoroethylene (PTFE), Teflon is renowned for its exceptional chemical resistance, low friction coefficients, and ability to withstand high temperatures. These properties make Teflon shaft seals ideal for applications in industries ranging from automotive to aerospace, where durability and reliability are paramount.

Understanding Teflon Shaft Seals Benefits and Applications

In addition to chemical resistance, Teflon seals excel at high-temperature applications. They can typically withstand temperatures ranging from -450°F to 500°F (-268°C to 260°C), making them suitable for environments that experience extreme thermal conditions. This thermal stability extends the lifespan of the seal, contributing to overall equipment longevity and reducing the frequency of replacements.

teflon shaft seal

Another compelling benefit of Teflon shaft seals is their low friction property. This feature minimizes wear on both the seal and the shaft, leading to smoother operation and improved efficiency within rotating machinery. As a result, machines operate more reliably, and energy consumption is reduced, which is a significant advantage in terms of cost savings and sustainability.

Teflon shaft seals come in various designs to suit different applications, including single-lip, double-lip, and customized configurations. Their versatility allows engineers to select the most suitable option based on the specific requirements of the application, such as pressure, temperature, and the nature of the fluids involved.

In conclusion, Teflon shaft seals offer unparalleled benefits in terms of chemical resistance, temperature resilience, and low friction performance. Their application can lead to enhanced operational efficiency and reduced maintenance costs, making them a preferred choice in many demanding industrial sectors. As technology continues to evolve, the use of advanced materials like Teflon is set to play an increasingly important role in the development of innovative sealing solutions for modern machinery.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories