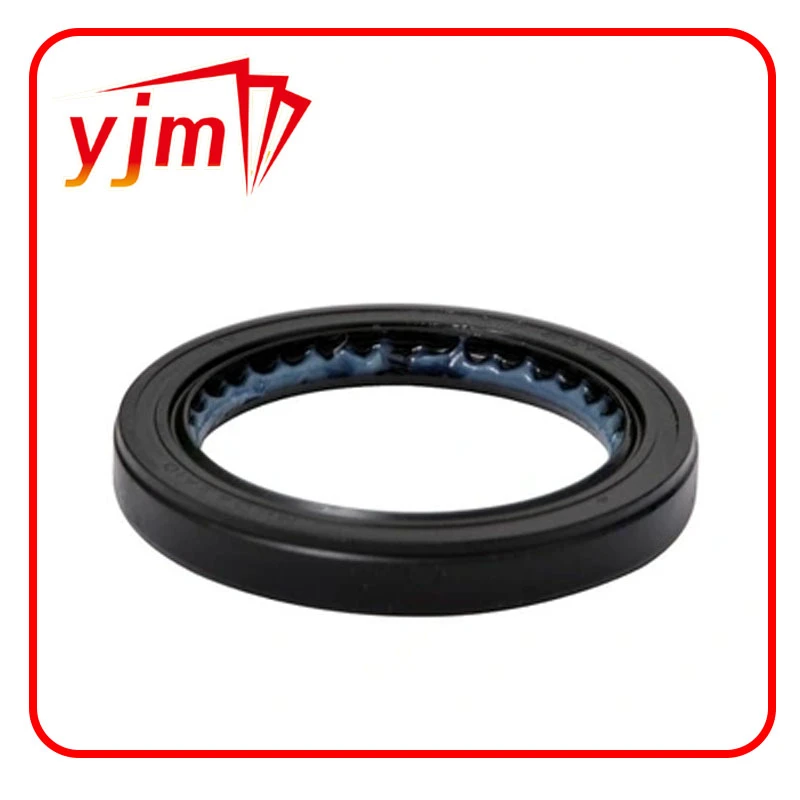

tc oil seal

Understanding TC Oil Seals Importance, Types, and Applications

Oil seals are essential components in various mechanical systems, playing a critical role in maintaining the efficiency and longevity of machinery. Among the many types of oil seals, TC oil seals have gained prominence due to their specific design and functionality. In this article, we will explore what TC oil seals are, their key features, types, applications, and the importance of selecting the right seal for your machinery.

What are TC Oil Seals?

TC oil seals, often referred to as lip seals, are designed to prevent the leakage of lubricants while keeping contaminants out of mechanisms. The name TC derives from their specific design, which typically includes a double-lip configuration—one lip is designed to retain oil while the other serves as a barrier to dust and debris. This configuration is particularly effective in environments where moisture and dirt can compromise a system's performance.

Key Features of TC Oil Seals

1. Double-Lip Design The double-lip structure provides enhanced sealing capabilities. The inner lip creates a tight seal against the rotating shaft, while the outer lip protects against dirt and moisture, ensuring longer sealing life.

2. Materials TC oil seals are commonly made from synthetic rubber, such as nitrile or polyurethane, which offers resistance to temperature fluctuations, wear, and chemical exposure. These materials are selected based on the specific requirements of the application.

3. Versatility With various sizes and configurations available, TC oil seals can be used in numerous applications across different industries, including automotive, industrial machinery, and agricultural equipment.

4. Ease of Installation TC oil seals can be easily installed into the housing of machines, requiring minimal equipment and effort. This ease of installation makes them a preferred choice for maintenance and replacement tasks.

Types of TC Oil Seals

TC oil seals can be categorized based on their design and application. Here are some common types

1. Standard TC Seals These are the most commonly used TC oil seals and are suitable for general purposes in various machinery.

2. Spring-loaded TC Seals These seals incorporate a metal spring on the inner lip to ensure constant tension against the shaft, providing better sealing performance, particularly in high-speed applications.

3. Heavy-duty TC Seals Designed for applications where extreme conditions are present, such as high pressure or temperature, these seals offer enhanced durability and resistance.

4. Customized TC Seals For specialized applications, manufacturers can produce custom TC oil seals tailored to specific dimensions, materials, and sealing requirements.

tc oil seal

Applications of TC Oil Seals

TC oil seals are widely used in numerous applications, including

1. Automotive They are used in engines, transmissions, differential housings, and other components to prevent fluid leaks and ensure optimal performance.

2. Industrial Machinery These seals can be found in pumps, motors, gearboxes, and conveyor systems, playing a vital role in maintaining machinery efficiency.

3. Agriculture In farming equipment, TC oil seals help protect against contaminants in hydraulic systems and engine components, resulting in better performance and reduced downtime.

4. Aerospace In aerospace applications, these seals are crucial for ensuring the reliability of various mechanical systems that require high levels of precision and performance.

Importance of Choosing the Right TC Oil Seal

Selecting the appropriate TC oil seal is critical to the overall functionality of your equipment. Factors to consider when choosing a seal include

1. Material Compatibility Ensure that the seal material is compatible with the fluids and temperatures it will encounter to prevent degradation.

2. Size and Fit Proper sizing is essential for effective sealing. An incorrectly sized seal can lead to leaks, reduced efficiency, and premature equipment failure.

3. Environmental Conditions Consider the operating environment, including exposure to abrasive materials, chemicals, and extreme temperatures, to select a seal that can withstand these conditions.

4. Application Requirements Each application may have specific sealing needs, such as pressure levels or speed, that must be considered during the selection.

Conclusion

TC oil seals play an indispensable role in mechanical systems by preventing leaks and protecting against contaminants. Their unique double-lip design, versatility, and ease of installation make them a popular choice across various industries. Understanding the different types and applications of TC oil seals is essential for ensuring the reliability and longevity of your machinery. When choosing a seal, consider factors like material compatibility, size, environmental conditions, and application requirements to ensure optimal performance. By investing in high-quality TC oil seals, you can enhance the efficiency and durability of your equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories