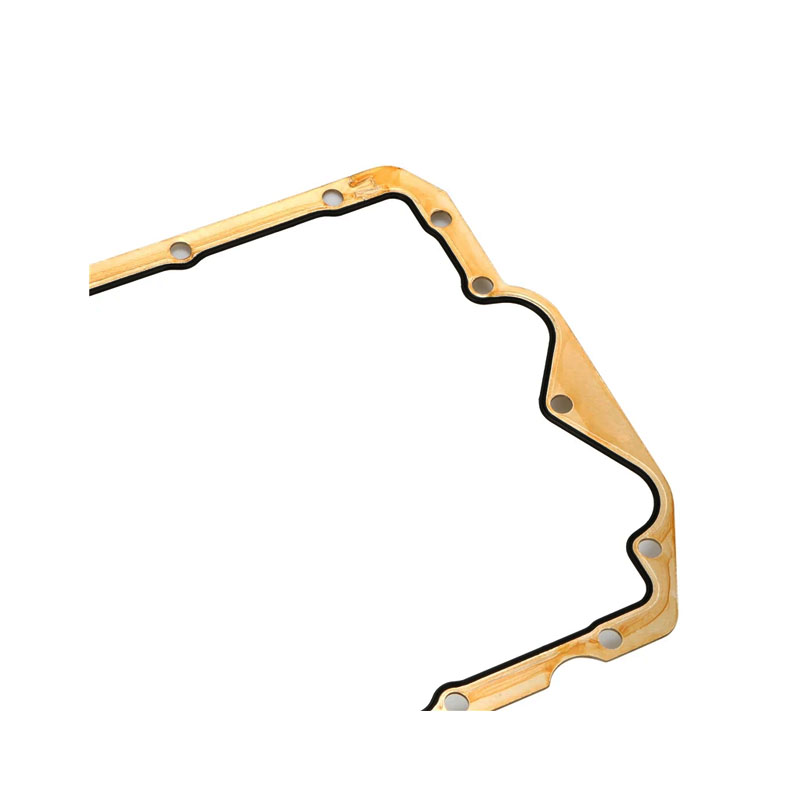

tcm oil seals

Understanding TCM Oil Seals Essential Components for Mechanical Applications

Oil seals, also known as lip seals or rotary shaft seals, play a crucial role in various mechanical systems by preventing the leakage of lubricants and keeping contaminants out. TCM oil seals, specifically, are designed and manufactured to meet the stringent performance standards required by different industries, including automotive, aerospace, and manufacturing. In this article, we will delve into the significance, types, applications, and advantages of TCM oil seals.

Significance of Oil Seals

In any mechanical system, lubricants are vital for reducing friction between moving parts, improving performance, and prolonging the life of machinery. Oil seals ensure that these lubricants stay confined within the components where they are needed while simultaneously blocking dust, dirt, and other debris from entering the system. This is particularly important in high-speed applications where even the smallest contamination can lead to failure or reduced efficiency.

Types of TCM Oil Seals

TCM oil seals come in various types, each tailored to specific requirements and applications

1. Rotary Shaft Seals These are designed for rotating shafts and are among the most common oil seals. They feature a flexible lips that presses against the shaft, creating a tight seal.

3. Double-lipped Seals These seals are equipped with two sealing lips, providing enhanced protection against leakage and contamination. They are especially useful in high-pressure applications.

4. V-Seals V-seals are used to protect against dirt and moisture while allowing shaft movement. They are commonly employed in heavy machinery and construction equipment.

Applications of TCM Oil Seals

The versatility of TCM oil seals makes them suitable for a wide range of applications. These seals are commonly found in

tcm oil seals

- Automotive Systems In vehicles, oil seals are used in engines, transmissions, and differential systems to maintain proper fluid levels and prevent leaks.

- Industrial Machinery Heavy machinery, such as excavators and bulldozers, utilize oil seals to protect hydraulic systems and ensure efficient operation.

- Aerospace In aircraft, oil seals are critical for engine components and hydraulic systems, contributing to safety and reliability.

- Home Appliances Many household devices, such as washing machines and dishwashers, employ oil seals to prevent leaks and maintain functionality.

Advantages of TCM Oil Seals

Using TCM oil seals comes with several advantages that enhance the performance and longevity of machinery

1. Leak Prevention TCM oil seals are engineered to provide a robust barrier against leaks, ensuring that lubricants stay where they are needed, which is essential for efficient operation.

2. Contamination Resistance By keeping dust and dirt out of lubricated areas, these seals help protect sensitive components and reduce wear and tear.

3. Extended Equipment Life By maintaining lubrication and minimizing contamination, TCM oil seals contribute to the overall longevity of machinery, reducing downtime and maintenance costs.

4. Innovative Materials TCM oil seals are manufactured from high-quality materials that can withstand extreme temperatures and pressures, ensuring reliable performance across a range of environments.

Conclusion

In conclusion, TCM oil seals are an integral part of many mechanical systems, offering critical advantages such as leak prevention, contamination resistance, and improved equipment life. Understanding the types, applications, and benefits of these seals can help industries select the right solutions for their specific needs. As technology progresses and machinery becomes more sophisticated, the importance of reliable components like TCM oil seals will only continue to grow. By ensuring optimal performance and longevity, TCM oil seals remain a vital investment across various sectors.

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

-

Understanding Vital Engine Seals: Key Gaskets in Diesel and Performance Engines

News Jun.13,2025

-

The Vital Role of Bearings in Marine and Boating Applications

News Jun.13,2025

-

Sealing the System: A Complete Guide to Engine Oil Gaskets

News Jun.13,2025

-

Sealing the Foundation: A Complete Guide to Engine and Transmission Pan Gaskets

News Jun.13,2025

-

Essential Bearings and Hubs for Marine Vessels and Trailers

News Jun.13,2025

-

Your Complete Guide to Automotive Oil Drain Plugs and Valves

News Jun.12,2025

Products categories