sunny oil seal

The Significance of Sunny Oil Seals in Modern Machinery

In the ever-evolving landscape of industrial machinery, the importance of reliable components cannot be overstated. Among these components, oil seals play a vital role in ensuring the efficiency and longevity of machinery. The concept of sunny oil seals brings to mind not only the functional aspect but also the potential for innovation in design and application.

Oil seals, also known as oil seals or lip seals, are vital components used to prevent the leakage of lubricants and the ingress of contaminants in various mechanical systems. The term sunny in conjunction with oil seals suggests an association with quality, performance, and perhaps a touch of optimism for engineers and technicians striving for peak operational efficiency.

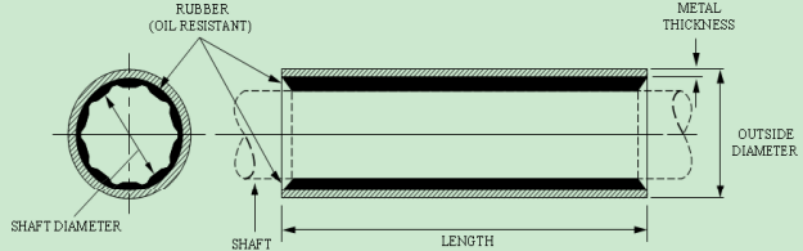

The Anatomy of an Oil Seal

Understanding the anatomy of an oil seal can help us appreciate its significance. An oil seal typically consists of three main components the sealing lip, the outer casing, and the spring. The sealing lip is designed to fit snugly against the rotating shaft, creating a barrier against the escape of lubricating oil. The outer casing holds the seal in place within the housing, and the spring ensures that the sealing lip maintains adequate contact with the shaft under varying operational conditions. The combination of these elements enables oil seals to perform effectively in a range of environmental conditions.

Applications Across Industries

Sunny oil seals are particularly relevant across various industries, from automotive and aerospace to manufacturing and construction. In the automotive sector, for instance, oil seals are critical in engines, transmissions, and differentials. They ensure that lubricants remain contained within the system, preventing wear and tear on moving parts and enhancing overall performance.

In the aerospace industry, the reliability of oil seals is paramount. These seals must endure extreme temperatures and pressures during flight, making quality a non-negotiable necessity. A failure of an oil seal in an aircraft could lead to catastrophic consequences. Thus, the development of advanced materials and innovative designs has become a focus for engineers aiming to create the most reliable sunny oil seals.

sunny oil seal

Additionally, in manufacturing and construction, oil seals facilitate the smooth operation of hydraulic equipment and heavy machinery. They play a crucial role in preventing contamination of fluids, which can lead to expensive repairs and downtime.

Factors Influencing Oil Seal Performance

Several factors influence the performance and lifespan of oil seals. These include the type of material used, the operating temperature, the pressure conditions, and the nature of the lubricating fluid. High-quality materials such as nitrile rubber, fluorocarbon, or silicone are often employed to withstand various environmental challenges. Furthermore, designing oil seals that can tolerate a wide range of temperatures and pressures is essential for ensuring that they function reliably in demanding conditions.

Innovations in Design and Technology

The future of sunny oil seals looks promising, with continuous advancements in materials science and engineering design. Companies are experimenting with new materials, such as thermoplastic elastomers (TPEs) and advanced composites, that offer enhanced resilience against wear and chemical degradation. Additionally, advanced computational modeling techniques allow engineers to optimize the design of oil seals for better performance and longevity.

Moreover, the integration of smart technology in oil seals opens up new frontiers in monitoring and maintenance. Sensors can be embedded into seals to track conditions such as temperature, pressure, and even the presence of lubricant leaks. This proactive approach to maintenance can significantly reduce downtime and extend the life of machinery.

Conclusion

In conclusion, sunny oil seals are indispensable components in the machinery that drives our modern world. Recognizing their critical role can motivate engineers and manufacturers to invest in high-quality designs and materials, ensuring that machines operate efficiently and reliably. As technology continues to evolve, so too will the capabilities of oil seals, paving the way for more innovative solutions that enhance performance across various sectors. Embracing the concept of sunny oil seals not only reflects a commitment to quality but also an optimistic outlook towards a future where machinery performs seamlessly in all conditions.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories