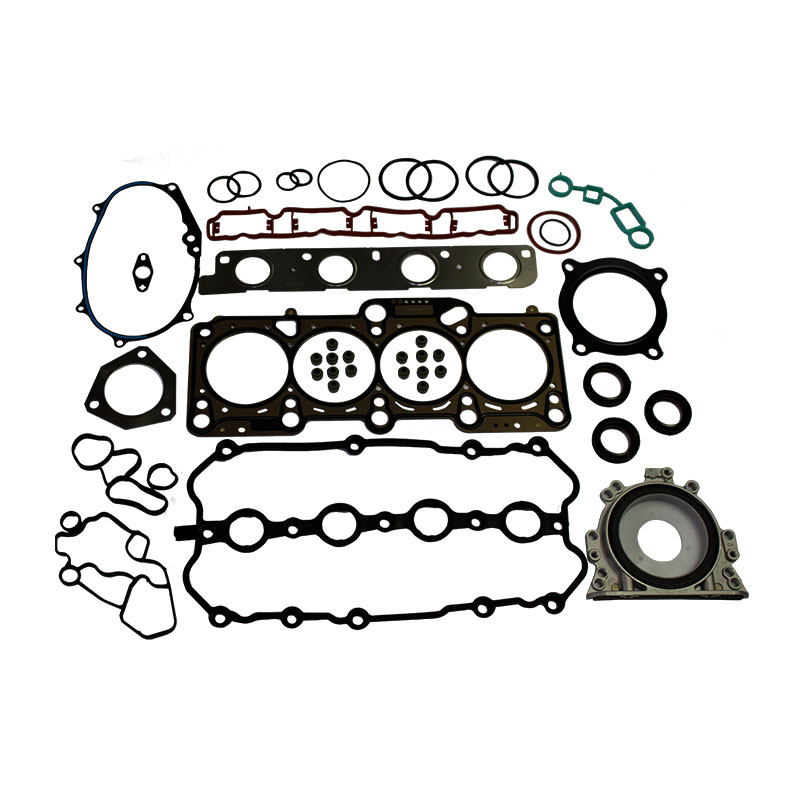

Sump Nut Washer Specifications and Installation Guide for Optimal Performance

Understanding Sump Nut Washers An Essential Component in Fluid Mechanics

In the realm of mechanical engineering and plumbing, specific components often play crucial roles in ensuring the efficient operation and longevity of systems. One such component that deserves attention is the sump nut washer. Although seemingly simple, this small yet vital part has a profound impact on the function of various systems, particularly in fluid containment and management.

What is a Sump Nut Washer?

A sump nut washer is a type of washer used in conjunction with a sump nut, which secures a drainage system or tank. These washers are typically made from materials that can withstand harsh environments, including rubber, metal, or composite materials. Their primary function is to create a seal that prevents leaks, ensuring that fluids remain contained within the system. This is especially critical in applications involving water, oil, and other liquids where leakage could have serious consequences.

Functions of Sump Nut Washers

1. Leak Prevention The most critical function of a sump nut washer is to prevent leakage. By providing a tight seal between the nut and the surface of the sump or tank, these washers help maintain integrity and prevent unwanted fluid loss.

2. Vibration Dampening In many applications, components experience vibrations due to operational processes. Sump nut washers can serve as buffers, absorbing some of these vibrations and reducing the risk of loosening or damage to the connections over time.

3. Corrosion Resistance Many sump environments are corrosive due to the fluids that they hold. Sump nut washers made from corrosion-resistant materials can prolong the life of the entire assembly by shielding critical components from damaging chemicals.

4. Facilitating Maintenance Since sump nut washers are easy to replace, they make maintaining systems more straightforward. In cases where washers wear out or become compromised, quick replacement can prevent more significant issues down the line.

Selecting the Right Sump Nut Washer

Choosing the correct sump nut washer is essential for ensuring optimal performance. Here are a few factors to consider

sump nut washer

- Material Compatibility The material of the washer should be compatible with the fluid it will be in contact with. For instance, rubber washers are ideal for water applications, while more robust materials like stainless steel might be better suited for oil or chemical containment.

- Size and Thickness It is crucial to match the washer's size with the sump nut and the mounting surface. An improperly sized washer can lead to inadequate sealing and potential leaks.

- Temperature and Pressure Ratings Depending on the application, the washer may need to withstand high temperatures or pressures. Ensure the chosen washer meets or exceeds the operational limits set by the specific application.

Common Applications of Sump Nut Washers

Sump nut washers find use in a variety of applications across different industries

1. Automotive In vehicles, sump nut washers are often used in oil pans and fuel systems, where secure seals are necessary to prevent leaks from impacting engine performance.

2. Plumbing In residential and commercial plumbing, these washers are crucial in sump pumps and drainage systems, where water containment is a priority.

3. Industrial Settings Many industrial systems, including chemical processing and manufacturing plants, utilize sump nut washers in their fluid handling systems to prevent spills and maintain safety.

Conclusion

In conclusion, while often overlooked, sump nut washers are indispensable components in a wide range of applications. Their primary role in providing a reliable seal to prevent leaks is critical in many settings, from automotive to industrial and plumbing systems. Understanding their functions, selecting the appropriate materials, and applying them correctly can significantly enhance system performance and longevity. As we continue to innovate in engineering and design, the importance of such components will only grow, emphasizing the need for knowledge and awareness in their selection and application.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories