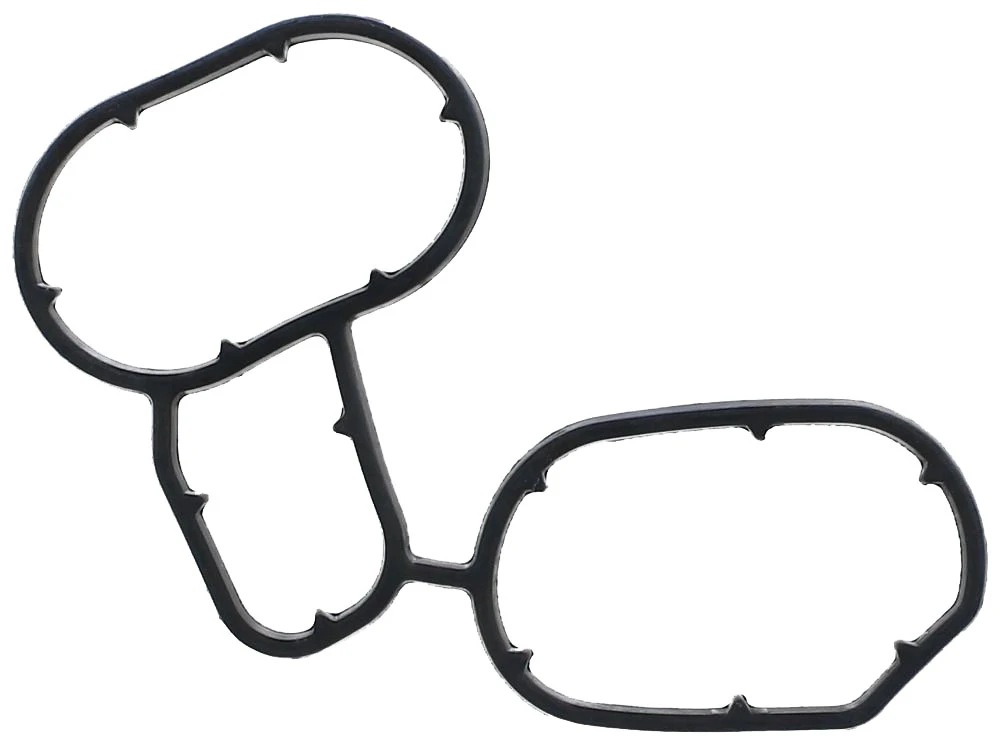

Oil Drain Sump Plug Washers Gasket 90430-12031

Tools such as the oil filter wrench set can greatly assist in the removal of stubborn sump bungs, reducing the risk of stripping threads or damaging the washer surface. Always inspect the washer after removing the sump bung for any signs of wear or damage. Even if it appears in good condition, replacing the washer during each oil change is a practice recommended by most professionals to maintain the integrity of the seal. Another critical factor in the effectiveness of sump bung washers is the use of appropriate lubricants. Certain washers, particularly those made from metal, may require a specific type of thread lubricant to ensure optimal performance. This helps in reducing friction during installation and provides additional sealing capacity. For those keen on sustainability, there are also sump bung washers made from recycled materials, offering the same performance level while contributing to environmental conservation efforts. Utilizing such products not only extends the life of your vehicle but also supports eco-friendly practices in automotive maintenance. In conclusion, sump bung washers, although small, play a substantial role in the overall efficiency of a vehicle's engine system. Understanding the different types available and their distinct advantages can help in selecting the right washer for your specific needs, thus enhancing the durability and performance of your vehicle. Always abide by professional advice regarding installation and replacement intervals to ensure a leak-free and long-lasting engine.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories