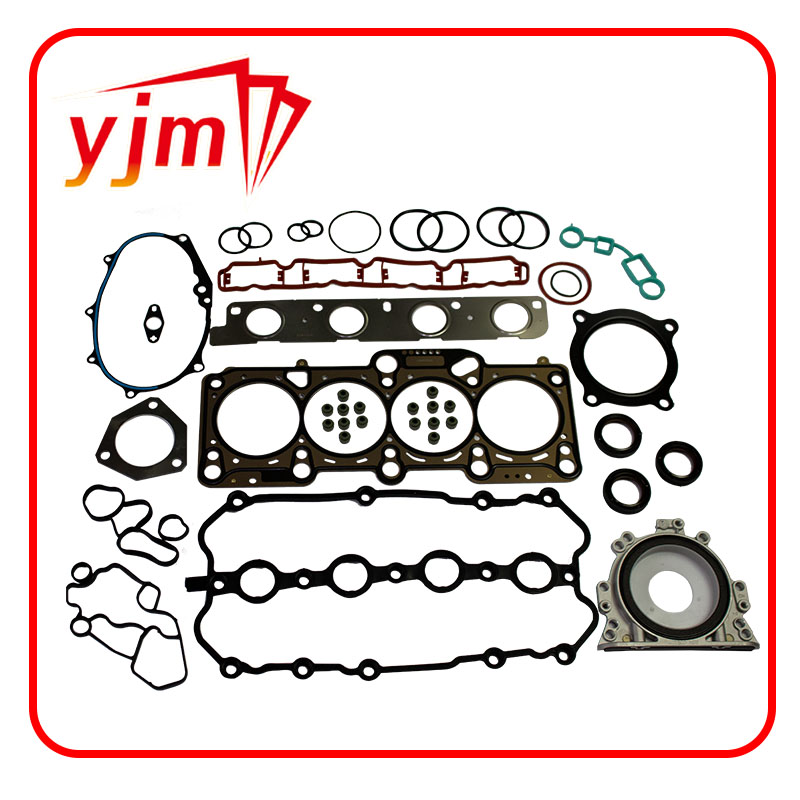

sump bung washer

Understanding the Importance of Sump Bung Washers

In various industrial applications, the integrity of seals and connections plays a crucial role in ensuring the safety, efficiency, and durability of equipment. One often-overlooked component is the sump bung washer, which is essential in maintaining the effectiveness of sump bungs in tanks and reservoirs. This article explores the significance of sump bung washers, their materials, applications, and maintenance considerations.

What is a Sump Bung Washer?

A sump bung washer is a sealing device used in conjunction with sump bungs, which are fittings used to drain or fill tanks and reservoirs. The washer is typically placed between the bung and the tank to create a tight, leaks-free seal. This is particularly important for storage tanks that hold various liquids, including hazardous materials, chemicals, and fuels. The primary function of the washer is to prevent liquid from leaking out, which can cause environmental hazards, safety risks, and financial losses.

Materials Used in Sump Bung Washers

The choice of material for sump bung washers is critical, as it needs to withstand various operating conditions. Common materials include rubber, silicone, neoprene, and cork. Each material has unique characteristics that suit specific applications

1. Rubber This is one of the most popular materials for sump bung washers due to its elasticity and ability to provide a tight seal. Rubber washers can accommodate slight variations in surface irregularities, making them effective for preventing leaks.

2. Silicone Known for its high-temperature resistance and flexibility, silicone washers are ideal for applications where high temperatures or varied chemical exposure is present. Their durability ensures long-lasting performance even under stress.

3. Neoprene This synthetic rubber material is resistant to oils and weathering, making it suitable for outdoor use and environments where chemical exposure is a concern. Neoprene washers provide good sealing capabilities while also being resistant to degradation.

4. Cork Although less common, cork washers can be used in specific applications where compressibility is required. Cork is also environmentally friendly and biodegradable, which can be a deciding factor for companies focusing on sustainability.

Applications of Sump Bung Washers

Sump bung washers are widely used in various industries, including

sump bung washer

- Petrochemical Industry In the storage of fuels and chemicals, the integrity of the tank seal is paramount. A faulty washer can lead to significant risks, including fire hazards or environmental contamination.

- Water Treatment Facilities These facilities often use sump bungs to manage water levels and remove sludge. Effective sealing ensures that treated water remains uncontaminated.

- Manufacturing In many manufacturing processes, fluids are stored in large tanks. Sump bung washers help manage these fluids safely, preventing spills that could disrupt operations.

- Automotive and Marine Applications These industries often require secure seals for fuel tanks, coolant systems, and oil reservoirs. Sump bung washers are crucial to maintaining system integrity.

Maintenance Considerations

To ensure the long life of sump bung washers, regular inspection and maintenance are recommended. Over time, washers can degrade due to environmental factors, chemical exposure, and mechanical stress. Signs of wear include cracks, brittleness, or deformation.

1. Regular Inspections Businesses should incorporate routine checks into their maintenance schedules. Any signs of deterioration should prompt immediate replacement to avoid leaks.

2. Proper Installation Ensuring that washers are installed correctly is crucial. Over-tightening can cause damage, while under-tightening may lead to leaks.

3. Choosing the Right Material Selecting the appropriate washer material for the specific application enhances performance and longevity. Companies should assess the environment and the nature of the fluids being contained when choosing materials.

4. Environmental Monitoring Keeping an eye on external conditions such as temperature and exposure to chemicals can help predict the lifespan of washers and initiate timely replacements.

Conclusion

Sump bung washers may seem like minor components, but their role in industrial safety and efficiency is significant. By understanding their importance, applications, and maintenance requirements, industries can enhance operational reliability and prevent costly and hazardous leaks. Investing in high-quality sump bung washers and implementing regular maintenance checks can safeguard both the environment and the bottom line.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories