Understanding Stuffing Box Mechanical Seals for Enhanced Equipment Performance and Reliability

Understanding Stuffing Box Mechanical Seals

Mechanical seals play a crucial role in various industries, particularly in the containment of fluids and gases in rotating equipment. One of the most common applications of mechanical seals is in stuffing boxes, which are designed to prevent leakage in pumps, mixers, and other machinery. A stuffing box mechanical seal is integral for maintaining operational efficiency, safety, and environmental compliance.

What is a Stuffing Box?

A stuffing box is an assembly that accommodates a rotating shaft and provides a method for sealing the space between the shaft and the housing. Traditionally, packing materials, such as braided fibers or other elastomers, are used to create this seal. However, mechanical seals have become more popular due to their superior performance and longevity.

How Do Stuffing Box Mechanical Seals Work?

A stuffing box mechanical seal consists of two primary components a stationary part that is fixed to the housing and a rotating part that is attached to the shaft

. These two components create a seal by pressing against each other, preventing leakage of the fluid or gas being contained. The sealing surfaces are precision-engineered to minimize wear and ensure a tight seal even under varying pressure and temperature conditions.When the machinery operates, the rotation of the shaft generates a certain amount of friction. In a properly designed mechanical seal, this friction creates a hydrodynamic film of the fluid, allowing for smooth operation without significant wear on the sealing surfaces. It's important to note that for optimal performance, mechanical seals must be installed with precise alignment to avoid premature failure.

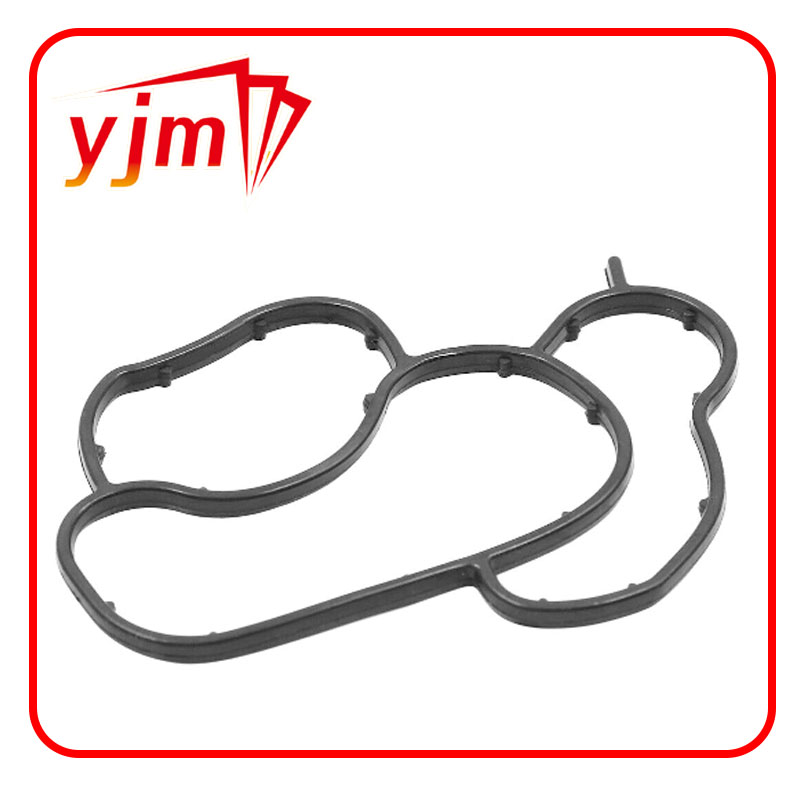

stuffing box mechanical seal

Advantages of Mechanical Seals Over Traditional Packing

Mechanical seals offer numerous advantages compared to traditional packing methods. Firstly, they significantly reduce leakage, which is critical for preventing environmental contamination and operational losses. Secondly, mechanical seals typically require less maintenance and downtime, translating to increased productivity and lower operational costs.

Moreover, stuffing box mechanical seals are capable of handling high pressure and temperature conditions. They provide better durability compared to packing, which can degrade over time due to wear and tear. The efficiency of a mechanical seal can also contribute to lower energy consumption, making the equipment more cost-effective in the long term.

Selecting the Right Mechanical Seal

When selecting a stuffing box mechanical seal, several factors must be considered 1. Operating Conditions Temperature, pressure, and the type of fluid being contained greatly influence the selection. 2. Material Compatibility The sealing materials must be compatible with the fluids to prevent chemical degradation and ensure longevity. 3. Seal Configuration Different applications may require specific designs, such as single, double, or cartridge seals, to accommodate unique operational demands.

Conclusion

Stuffing box mechanical seals are essential components that ensure the effective operation of rotating machinery across various sectors, including oil and gas, chemical processing, and water treatment. With their advantages in leakage prevention, maintenance reduction, and energy efficiency, they are a superior choice compared to traditional packing methods. As industries continue to prioritize safety and environmental compliance, the use of mechanical seals in stuffing boxes will only become more prominent. Understanding the intricacies of these seals is vital for engineers and maintenance personnel to ensure optimal performance and reliability in their equipment.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories