stern tube bearing on ship

The Role of Stern Tube Bearings in Ship Design and Performance

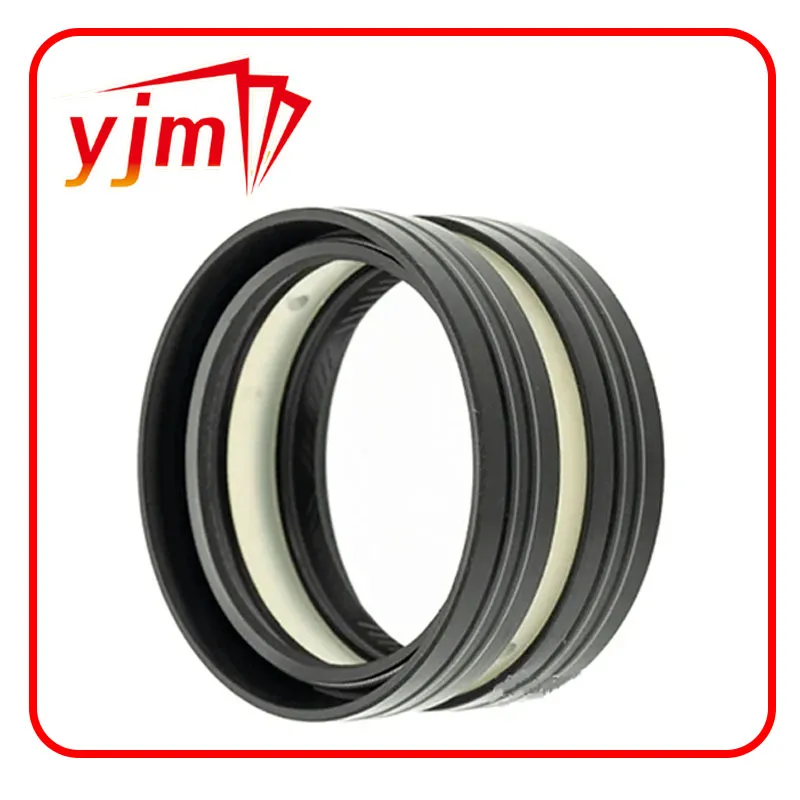

Stern tube bearings are critical components in the design and performance of marine vessels, playing a vital role in the effective operation of a ship's propulsion system. Located at the aft of the vessel, the stern tube connects the ship's propulsion shaft to the hull, allowing for smooth transmission of power from the engine to the propeller while also maintaining effective sealing and aligning practices. Understanding the intricacies of stern tube bearings is essential for engineers and naval architects aiming to enhance vessel performance, reliability, and longevity.

Function and Importance

The main function of stern tube bearings is to support the propulsion shaft and minimize wear and tear due to friction during operation. These bearings are designed to accommodate the longitudinal and radial loads placed on them due to the rotating shaft and the weight of the structure itself. As the vessel navigates through water, the stern tube bearings provide guidance and support, preventing axial movement and maintaining alignment with the propeller system, which is critical for efficient propulsion.

Given the harsh marine environment, stern tube bearings are typically constructed from high-strength materials such as bronze, composites, or various alloys, which not only provide durability but also enhance resistance to corrosion from saltwater. In addition to their structural task, stern tube bearings also perform a crucial sealing role, preventing water ingress into the vessel and, conversely, minimizing oil leakage from the lubrication systems.

Types of Stern Tube Bearings

Stern tube bearings can be classified into several types, including

1. Plain Bearings These cylindrical bearings provide a sliding surface for the shaft and are often used in larger vessels. They require a lubrication system to maintain a continuous film of oil and reduce friction.

2. Water-lubricated Bearings These environmentally friendly bearings utilize seawater as the lubricant. While they have benefits in reducing pollution and maintenance costs, they can be prone to faster wear if not adequately monitored.

stern tube bearing on ship

3. Hybrid Bearings These incorporate characteristics from both plain and water-lubricated bearings. They may utilize oil as the primary lubricant but contain a water channel to cool the system and ensure efficient operation.

Selecting the appropriate type of stern tube bearing depends on various factors, including the size of the vessel, operating conditions, maintenance schedules, and the overall design philosophy of the ship.

Maintenance and Challenges

Maintenance of stern tube bearings is crucial to ensuring their seamless operation and prolonging their lifespan. Regular inspections are necessary to identify signs of wear, corrosion, or misalignment. Vessels may experience issues such as overheating, vibration, or abnormal wear patterns, which can indicate lubrication failures or incorrect installation. Such challenges can lead to costly repairs and potential downtime, emphasizing the importance of preventative maintenance strategies.

In recent years, advancements in technology have enabled the development of condition monitoring systems for stern tube bearings. These systems use sensors to provide real-time data on bearing performance, allowing for predictive maintenance that can address issues before they escalate into major problems.

Environmental Considerations

With increasing awareness of environmental impact, the maritime industry is also focusing on the ecological consequences of stern tube bearings. Traditionally, the use of oil-based lubricants poses risks in the event of leaks, prompting a shift toward more sustainable solutions such as water-lubricated bearings. This transition not only reduces pollution but also aligns with regulations aimed at minimizing the maritime sector's impact on marine ecosystems.

Conclusion

Stern tube bearings are indispensable components in the propulsion systems of modern ships, contributing significantly to their overall performance and reliability. Continuous developments in material science and engineering practices promise enhancements in both the efficiency and sustainability of stern tube bearings. As the shipping industry navigates the challenges of modernization and environmental preservation, the focus on advanced bearing technologies will further cement the role of stern tube bearings in the future of marine engineering. By investing in proper maintenance and adopting innovative solutions, ship operators can ensure that their vessels operate smoothly, efficiently, and environmentally responsibly for years to come.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories