Impact of Stern Tube Bearings on Ship Performance and Efficiency Analysis

The Role and Function of Stern Tube Bearings on Ships

Stern tube bearings are crucial components in maritime engineering, pivotal for the smooth operation of a ship's propulsion system. These bearings support the stern tube, which is the cylindrical component that connects the ship's hull to the propeller shaft, facilitating the transfer of power from the main engine to the propeller. Understanding the function, design, and maintenance of stern tube bearings is essential for optimizing vessel performance and ensuring safety at sea.

Functionality

The primary function of a stern tube bearing is to reduce friction between the rotating shaft and the stationary hull of the ship. The propeller shaft, which transmits power from the engine, rotates at high speeds, creating significant forces that could lead to excessive wear without proper support and lubrication. Stern tube bearings are designed to accommodate these forces while maintaining alignment and stability.

Typically, these bearings are fabricated from materials such as bronze or composite materials, designed to withstand harsh marine environments, including saltwater exposure, fluctuating temperatures, and high pressures. In addition to supporting the shaft, stern tube bearings also play a vital role in absorbing vibrations and minimizing noise, contributing to the overall comfort on board the vessel.

Types of Stern Tube Bearings

Several types of stern tube bearings are available, each suited to specific vessel types and operational demands. The two primary categories are

1. Plain Bearings These are the most common type, where a smooth surface reduces friction between the shaft and bearing. Most modern vessels utilize lubricated plain bearings, often using seawater or oil as the lubricant, ensuring efficient operation and minimizing wear.

2. Hydrodynamic Bearings These bearings use a liquid film to separate the shaft from the bearing surface, creating a cushion that dramatically reduces friction. This design helps to enhance energy efficiency and extend the lifespan of both the shaft and the bearing.

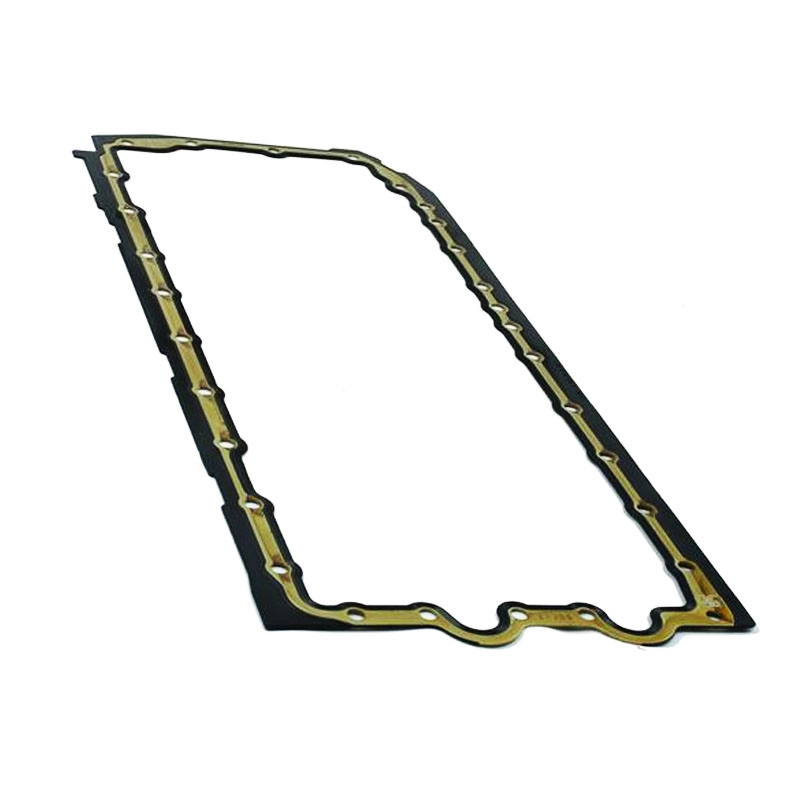

stern tube bearing on ship

Design Considerations

The design of stern tube bearings incorporates various factors to ensure optimal performance. The bearing must be engineered to handle the axial and radial loads imposed by the propeller's thrust. Additionally, the inner diameter of the bearing must align with the outer diameter of the shaft, allowing for smooth rotation.

Moreover, as ships often operate in varying conditions, including rough seas and heavy loading, bearings must also account for thermal expansion and potential misalignment. Advanced engineering techniques and materials are often employed to ensure that these bearings can withstand both operational stresses and environmental challenges.

Maintenance

Regular maintenance of stern tube bearings is essential for preventing failures that could lead to costly repairs or even accidents at sea. Maintenance practices typically include regular inspections to check for wear, corrosion, and proper lubrication levels. The use of advanced monitoring systems can also provide real-time data regarding the condition of the bearings, enabling proactive maintenance strategies.

Operators must ensure that the bearings are adequately lubricated to prevent metal-to-metal contact, which can lead to excessive wear and eventual bearing failure. Depending on the vessel's operating conditions, routine replacements may be necessary to maintain optimal performance.

Conclusion

Stern tube bearings are integral to the reliable operation of marine vessels. Their ability to support the propulsion shaft, reduce friction, and absorb vibrations directly impacts the efficiency, safety, and longevity of the ship. As maritime technology advances, the design and materials used in stern tube bearings continue to evolve, enhancing their performance and durability in challenging maritime environments. Through diligent design, regular maintenance, and adherence to best practices, ship operators can ensure that their vessels perform optimally, providing safe and efficient transportation across the world's oceans.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories