Impact of Stern Tube Bearings on Ship Performance and Efficiency

The Role of Stern Tube Bearings in Ship Design and Operations

Stern tube bearings are critical components in the marine engineering industry, playing a vital role in the smooth operation of marine vessels. Located at the aft (rear) part of the ship, the stern tube connects the ship’s hull with the propeller shaft, providing a pivotal link between the engine and the ship’s propulsion system. Understanding the functionality and importance of stern tube bearings can enhance tribological design and maintenance practices in marine engineering.

Functionality of Stern Tube Bearings

The primary function of a stern tube bearing is to support the propeller shaft and allow it to rotate freely while minimizing friction. This is crucial because the propeller shaft is subjected to substantial forces as it rotates, including axial, radial, and torsional loads. The design of stern tube bearings must account for these stresses while ensuring durability and reliability under various operational conditions.

Stern tube bearings are typically made from materials capable of withstanding harsh marine environments, including high pressures and corrosive seawater. Common materials include bronze, composite materials, and various types of plastics. Each material offers different advantages in terms of wear resistance, load capacity, and lubrication properties.

Types of Stern Tube Bearings

There are several types of stern tube bearings used in modern vessels

1. Sleeve Bearings These consist of a cylindrical piece of bearing material that fits around the shaft. Sleeve bearings are commonly used in small to medium-sized vessels due to their simplicity and effectiveness.

2. Hydrodynamic Bearings These bearings use the movement of water and oil to create a lubricating film between the shaft and the bearing surface. This type minimizes friction and wear, making them suitable for high-speed applications.

3. Journal Bearings These bearings support the shaft and allow for axial and radial movements. They are crucial for maintaining alignment within the stern tube and preventing vibration.

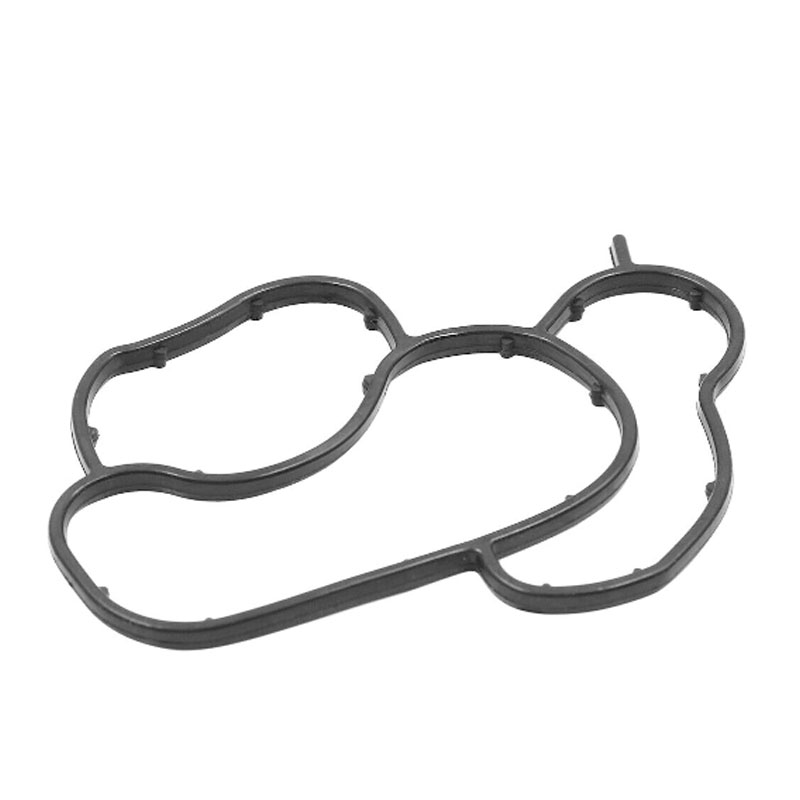

stern tube bearing on ship

4. Ball Bearings Although less common in marine applications, ball bearings can be utilized in systems where reduced contact friction is essential, providing high-speed capability.

Lubrication and Maintenance

Proper lubrication is essential for the performance of stern tube bearings. Lubricants reduce friction, eliminate wear, and protect against corrosion. Different lubrication methods are applied based on the type of bearing used. Common approaches include water-lubricated systems, oil-lubricated systems, and grease lubrication.

Routine maintenance is vital for the longevity and efficiency of stern tube bearings. Regular inspections can help identify potential issues such as wear, corrosion, or misalignment. Common maintenance practices involve checking lubricant levels, examining bearing surfaces for damage, and monitoring the alignment of the propeller shaft.

The integration of advanced monitoring technologies, such as vibration analysis and temperature sensors, has significantly improved maintenance practices. These technologies provide valuable data on the condition of bearings, enabling proactive interventions before major failures occur.

Challenges and Innovations

Stern tube bearings face several challenges, such as the effects of cavitation, corrosion, and debris accumulation. Cavitation can lead to damaging pressure fluctuations, ultimately resulting in pitting on bearing surfaces. Innovations in bearing materials and designs, such as the use of composite materials and improved lubrication systems, help address these challenges.

Additionally, as environmental regulations become stricter, there is an increasing demand for eco-friendly solutions. The development of water-lubricated bearings contributes to reducing the environmental impact of shipping activities, as they eliminate the risk of oil pollution in marine environments.

Conclusion

In summary, stern tube bearings are an essential component of modern vessel designs, contributing significantly to the efficiency and reliability of marine propulsion systems. Ongoing innovations in materials and lubrication technologies, combined with rigorous maintenance practices, will ensure that stern tube bearings continue to meet the demands of marine engineering. As the maritime industry evolves, a deeper understanding of these components will be vital in supporting advancements in ship design and operation, ultimately enhancing the sustainability of maritime activities.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories