Exploring the Features and Benefits of So Giant Oil Seals for Industrial Applications

Understanding So Giant Oil Seal Key Features and Applications

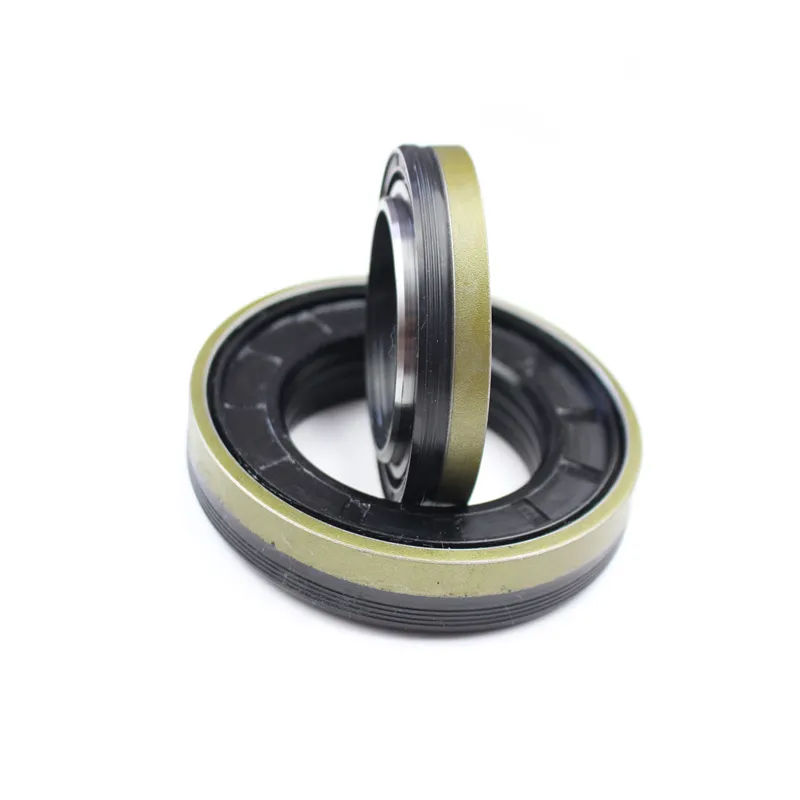

Oil seals, also known as shaft seals or lip seals, are critical components used to prevent leakage of fluids in machinery and engines. Among the various types of oil seals, so giant oil seal refers to those designed for larger applications, catering to heavy machinery and industrial equipment. This article explores the key features, materials, and applications of so giant oil seals, highlighting their significance in ensuring operational efficiency and equipment longevity.

Key Features of So Giant Oil Seals

1. Size and Durability So giant oil seals are manufactured to withstand substantial pressure and accommodate larger shaft diameters. They are engineered from tough materials that can resist wear and tear, making them suitable for demanding industrial environments.

2. Material Composition The materials used in the manufacture of giant oil seals are critical for their performance. Commonly used materials include nitrile rubber, polyurethane, and fluorocarbon, each selected for its unique properties. For instance, nitrile rubber is excellent for oil resistance, while fluorocarbon offers better temperature resistance, making it ideal for extreme environments.

3. Design Features These seals often include a lip design that creates a reliable barrier against fluid leakage. The shape and flexibility of the lip contribute to their sealing effectiveness and ability to accommodate misalignment of shafts. Additionally, some designs may include metal reinforcements to increase structural integrity.

Applications of So Giant Oil Seals

so giant oil seal

1. Heavy Machinery So giant oil seals are extensively used in heavy equipment such as bulldozers, excavators, and cranes. These machines often operate in harsh environments and require reliable sealing solutions to prevent hydraulic fluid leaks and maintain optimal performance.

2. Automotive Industry In vehicles, giant oil seals can be found in engines, transmissions, and differentials. They ensure that vital fluids such as engine oil and transmission fluid remain contained, thereby promoting efficient operation and reducing the risk of component failure.

3. Agricultural Equipment Tractors and other agricultural machinery rely on so giant oil seals to protect key components from dirt, dust, and moisture while preventing leaks. This is essential for ensuring that equipment operates smoothly during critical farming operations.

4. Industrial Machinery Applications in manufacturing and industrial settings often require so giant oil seals to function in diverse conditions. They can be found in gearboxes, pumps, and compressors, where they play a key role in preserving the functionality and safety of machinery.

Conclusion

So giant oil seals are indispensable components in a wide range of applications, particularly where heavy machinery and industrial equipment are concerned. Their robust construction and material properties ensure reliable performance, preventing fluid leaks and maintaining efficiency. As industries continue to evolve and push the limits of machinery capabilities, the importance of high-quality oil seals cannot be overstated. Investing in the right type of so giant oil seals not only enhances equipment longevity but also reduces maintenance costs and downtime, ultimately contributing to a more efficient operation.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories