Single Lip Oil Seal for Enhanced Sealing Performance and Reliability in Applications

Understanding Single Lip Oil Seals Function, Design, and Applications

Oil seals, crucial components in various machinery, are primarily designed to prevent the leakage of lubricating fluids, thereby protecting mechanical systems from contaminants. Among the different types of oil seals, the single lip oil seal stands out for its simplicity, efficiency, and wide range of applications. This article delves into the design, function, and applications of single lip oil seals, providing insight into their importance in mechanical engineering.

What is a Single Lip Oil Seal?

A single lip oil seal is a sealing device used to retain oil or lubricants in machinery while preventing the ingress of dirt, dust, and water. As the name suggests, it features a single elastomeric lip that makes contact with the rotating shaft, creating a tight seal. Typically made from rubber, polyurethane, or other flexible materials, the lip is designed to deform slightly under pressure, allowing it to adapt to the shaft’s surface while maintaining an effective seal.

Design Features

The design of a single lip oil seal is relatively straightforward yet highly effective. The key components include

1. Seal Body The body of the seal is usually made from a rigid material like metal or plastic, providing structural integrity.

2. Elastic Lip This part is the primary sealing component. Its ability to flex and conform to the shaft surface is essential for effective sealing. The lip is often designed with a specific angle to optimize sealing performance and minimize wear.

3. Spring Many designs incorporate a garter spring that helps maintain the tension of the lip against the shaft. This feature enhances sealing capability, especially in dynamic applications where the shaft is in constant motion.

4. Dust Guard In some designs, a dust lip or guard is included. This additional feature helps prevent contaminants from reaching the primary seal lip, thus extending the life of the oil seal.

Functionality

The primary function of a single lip oil seal is to prevent leakage of lubricants from within mechanical systems. By creating a barrier between the rotating shaft and the external environment, these seals play a vital role in

2. Contaminant Exclusion Preventing dirt, dust, and water from penetrating the machinery, which can lead to premature wear, corrosion, and failure.

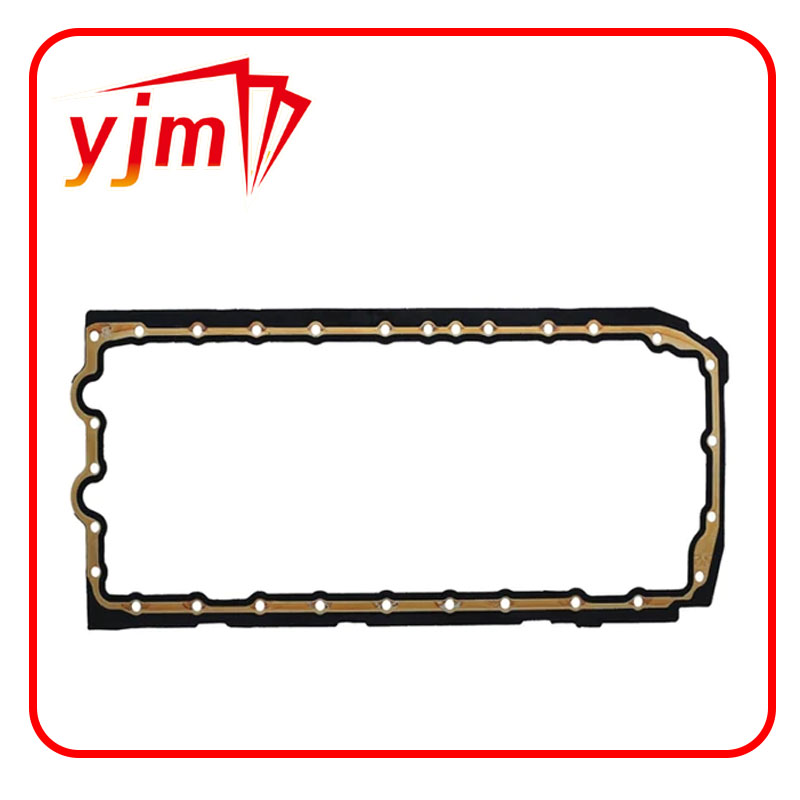

single lip oil seal

3. Pressure Management In applications where pressure differentials exist, single lip oil seals help maintain the required pressure levels, ensuring efficient operation.

Applications

Single lip oil seals are prevalent in various industries due to their versatility and reliability. Some common applications include

1. Automotive Industry These seals are extensively used in engines, gearboxes, and wheel hubs to prevent oil leaks and maintain lubrication.

2. Industrial Machinery Single lip oil seals are found in various types of equipment, including pumps, compressors, and conveyor systems, where they protect bearings and gears from oil loss and contamination.

3. Agricultural Equipment Tractors and other farming machinery rely on these seals to ensure optimal performance while minimizing maintenance needs.

4. Household Appliances Many appliances, such as washing machines and vacuum cleaners, incorporate single lip oil seals to prevent fluid leaks and protect internal components.

Advantages

The advantages of using single lip oil seals include

1. Simplicity Their straightforward design makes them easy to install and replace, saving time and costs on maintenance.

2. Cost-Effectiveness Typically, they are more affordable compared to double lip or more complex seals.

3. Low Friction The single lip design ensures minimal friction against the shaft, enhancing the overall efficiency of the machinery.

Conclusion

Single lip oil seals play an essential role in ensuring the efficiency and longevity of a wide range of mechanical systems. With their effective sealing capabilities, simple design, and broad applicability, they are a key component in the engineering landscape. Understanding their functionality, design features, and applications not only highlights their importance but also emphasizes the need for proper maintenance and selection in industrial practices. As technology advances, the development of improved materials and designs will continue to enhance the performance and reliability of these critical sealing devices.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories