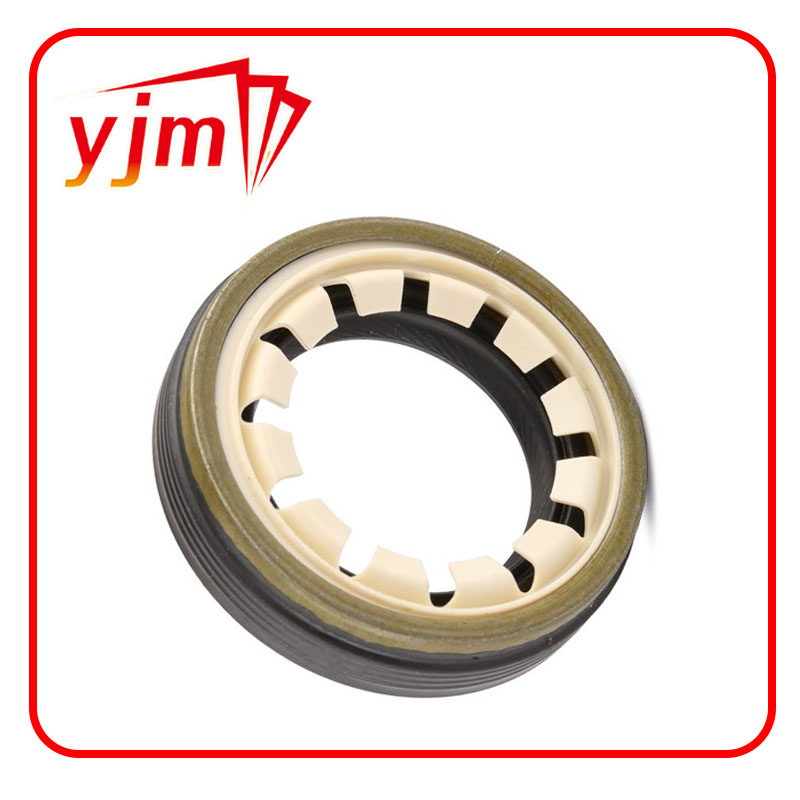

single lip oil seal

Understanding Single Lip Oil Seals Functionality and Applications

Single lip oil seals, also known as single lip seals or simply oil seals, play a crucial role in various mechanical applications. Their primary function is to prevent the leakage of lubricants and the ingress of contaminants into machinery systems. This is essential for ensuring the longevity and efficiency of mechanical components, particularly in automotive, industrial, and aerospace applications. In this article, we will explore the structure, functionality, and applications of single lip oil seals, along with the materials used in their construction.

Structure of Single Lip Oil Seals

A single lip oil seal consists of a flexible sealing lip that makes contact with a shaft to create a seal. Typically, the construction includes a metal casing that provides structural support and a rubber or elastomeric lip that deforms to fill the gap between the shaft and the housing. The seal operates under a specific amount of radial compressive force, allowing the lip to conform to the surface of the shaft while preventing the escape of oil or grease.

The design of the sealing lip plays a pivotal role in the performance of the seal. The angle, thickness, and the material of the lip can significantly affect the sealing action and the overall durability of the seal. The inner diameter of the seal typically fits snugly onto the shaft, while the outer diameter is designed to fit securely into the housing.

Functionality

The primary purpose of a single lip oil seal is to contain lubricants within a system while simultaneously blocking contaminants such as dirt, dust, and moisture from entering. A well-functioning oil seal creates a reliable barrier that enables machinery to operate smoothly and efficiently.

One of the key features of single lip oil seals is their ability to handle dynamic applications, where the sealed shaft is in constant rotation

. The lip design provides low friction, minimizing wear while maintaining an effective seal. This functionality is critical in applications such as engines, gearboxes, and pumps, where the performance of lubricants directly affects the efficiency and operational life of the equipment.Applications

Single lip oil seals are widely used in numerous industries, owing to their versatility and effectiveness. Here are a few notable applications

single lip oil seal

1. Automotive Industry Single lip oil seals are commonly found in engines, transmissions, and wheel bearings. They help in retaining oil, ensuring that the lubricating properties are maintained, which is vital for reducing friction and wear in moving parts.

2. Industrial Machinery In manufacturing equipment, oil seals prevent lubricant loss which can lead to overheating and equipment failure. They are used in conveyor systems, pumps, and hydraulic systems, significantly contributing to the reliability of manufacturing processes.

3. Aerospace Applications The aerospace industry requires seals that can withstand extreme temperatures and pressures. Single lip oil seals are also utilized in various aircraft components, ensuring optimal performance under challenging environments.

4. Household Appliances Many household appliances, such as washing machines and dishwashers, utilize single lip oil seals to prevent leaks in their operational mechanisms, thereby enhancing durability and performance.

Materials Used

The choice of material for single lip oil seals is crucial for their effectiveness. Common materials include nitrile rubber (NBR), fluorocarbon rubber (FKM), and silicone rubber, each offering various temperature resistance and chemical compatibility.

- Nitrile Rubber (NBR) Known for its excellent oil resistance, NBR is the most common material used for oil seals, particularly in automotive applications. - Fluorocarbon Rubber (FKM) This material is preferable when dealing with high temperatures and harsh chemical environments, making it suitable for aerospace applications.

- Silicone Rubber While not as oil-resistant as NBR, silicone rubber can function well in extreme temperature ranges, making it suitable for various applications where thermal stability is essential.

Conclusion

In summary, single lip oil seals are integral components in many mechanical systems. They ensure efficient operation by containing lubricants and preventing contaminants from entering. With varied applications across industries and a range of materials tailored to specific needs, these seals contribute significantly to machinery reliability and performance. As technology advances, the design and materials of single lip oil seals will continue to evolve, further enhancing their functionality and application range.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories