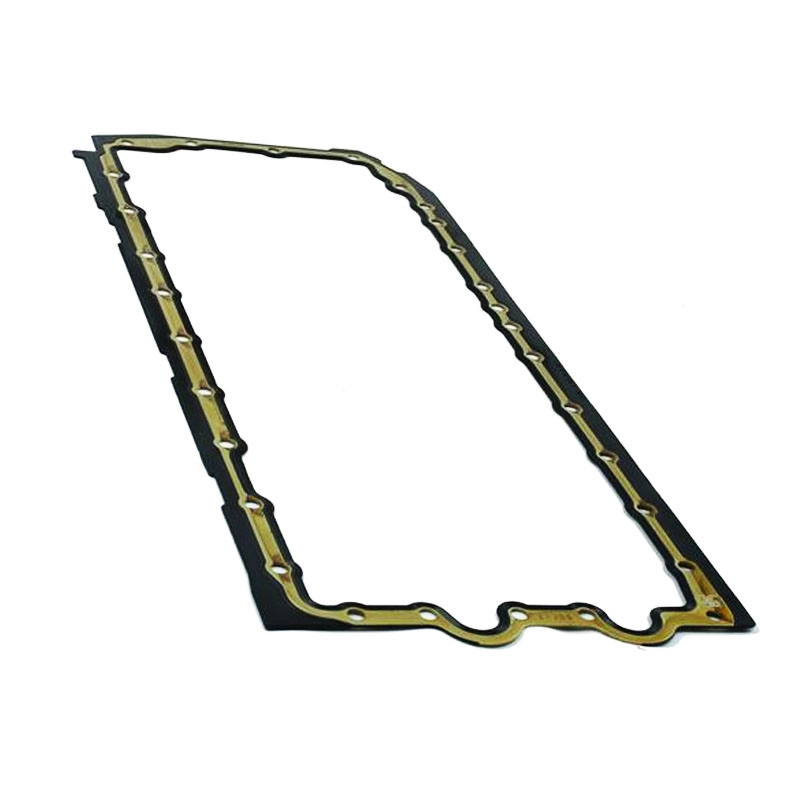

silicone oil seal

Silicone Oil Seal A Critical Component in Modern Engineering

Silicone oil seals are essential components in a wide array of industrial applications, providing durability, flexibility, and resistance to various environmental factors. These seals are made from silicone rubber, a polymer known for its excellent thermal stability, chemical resistance, and low-temperature performance. This unique combination of properties makes silicone oil seals particularly suitable for use in extreme conditions, where traditional seals may fail.

One of the primary advantages of silicone oil seals is their ability to withstand high temperatures. Many industrial applications involve exposure to heat, which can degrade standard rubber seals. Silicone, on the other hand, can handle temperatures ranging from -60°C to 250°C (-76°F to 482°F) without losing its sealing integrity. This feature is invaluable in automotive applications, particularly in engines and transmission systems where heat is a constant factor.

Moreover, silicone seals are highly resistant to various chemicals, including oils, fuels, and solvents. This makes them ideal for use in the petrochemical industry, where seals must maintain their functionality in the presence of aggressive substances. The chemical inertness of silicone also ensures that it does not react with the fluids it seals, preventing contamination and preserving the performance of the system.

silicone oil seal

Another important property of silicone oil seals is their flexibility and elasticity. Unlike other materials, silicone retains its flexibility over a wide range of temperatures, allowing it to effectively adapt to any changes and maintain a strong seal. This is critical in applications that experience vibration or movement, such as in machinery and automotive environments. The ability of silicone seals to deform without losing their sealing capability contributes significantly to the overall reliability of equipment.

In addition to their functional benefits, silicone oil seals also offer advantages in terms of longevity and maintenance. The durability of silicone against environmental factors such as UV light, ozone, and humidity means that these seals have a longer service life compared to conventional materials. As a result, industries can reduce downtime and maintenance costs associated with frequent seal replacements, leading to increased productivity.

Furthermore, the versatility of silicone allows for the design of seals in various shapes and sizes, tailored to specific needs. Whether it’s in automotive, aerospace, or manufacturing industries, silicone oil seals can be custom-engineered to provide the perfect fit and function.

In conclusion, silicone oil seals play a vital role in modern engineering, offering a unique blend of high-temperature resistance, chemical inertness, flexibility, and prolonged lifespan. As technology continues to advance, the demand for reliable sealing solutions will grow, making silicone oil seals an indispensable part of various industrial applications. Their exceptional properties ensure that they will remain a favored choice for engineers and manufacturers alike.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories