Shaft Seal Size Specifications and Guidelines for Optimal Performance and Fit

Understanding Shaft Seal Dimensions Key Considerations and Importance

Shaft seals are crucial components in various mechanical systems, serving the essential purpose of preventing the escape of fluids and protecting sensitive interior machinery from contaminants. These seals are commonly used in applications such as pumps, motors, and gearboxes, where the shaft penetrates an outer enclosure. Understanding the dimensions and specifications of shaft seals is imperative for ensuring proper function and longevity of equipment.

Importance of Shaft Seal Dimensions

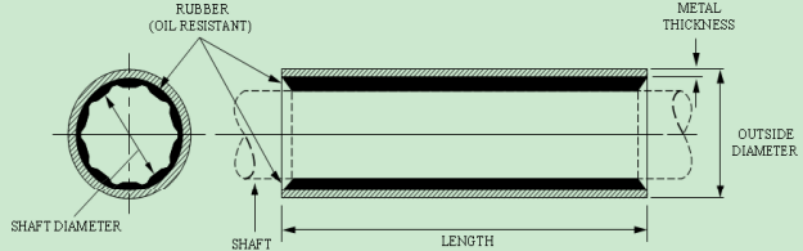

The performance of a shaft seal largely depends on its dimensions. The primary parameters to consider include the inner diameter (ID), outer diameter (OD), and width (or thickness) of the seal. Each of these dimensions plays a pivotal role in the seal’s ability to establish a tight fit and maintain a barrier against leakage.

1. Inner Diameter (ID) This is the critical measurement that corresponds to the diameter of the shaft it seals. An appropriately sized ID ensures a snug fit on the shaft, minimizing the potential for leakage. If the ID is too large, fluids may escape around the shaft. Conversely, if it’s too small, it may cause unnecessary friction, leading to premature wear or damage to both the seal and the shaft.

2. Outer Diameter (OD) The OD measurement is significant for the seal’s contact with the housing. A correctly sized OD ensures that the seal is adequately seated in the housing without too much compression. Over-compression can lead to seal failure, while under-compression may result in gaps that allow contaminants to enter.

3. Width The width of the seal affects the area of contact with the shaft and the housing. Wider seals can provide more surface area for fluid containment, potentially improving performance and longevity. However, selecting the width should also consider the space available and the specific design parameters of the machinery in use.

Material Considerations

shaft seal dimensions

Apart from physical dimensions, the material of the seal also plays a crucial role in its effectiveness. Common materials for shaft seals include rubber, silicone, and thermoplastic elastomers. Each material has unique characteristics regarding temperature tolerance, chemical resistance, and wear properties. When selecting a shaft seal, it is vital to consider the operating environment, including the type of fluids being contained, temperature ranges, and exposure to potential contaminants.

Measurement Standards

Shaft seal dimensions are governed by various industry standards, which help ensure compatibility and interchangeability among different manufacturers. Common standards include ANSI, ISO, and SAE. These standards provide guidelines on dimensions and tolerances, making it easier for engineers and technicians to select appropriate seals without encountering fitting issues.

Installation and Maintenance

Proper installation is essential for the optimal performance of shaft seals. Misalignment or improper seating can lead to early failure and leakage. It is advisable to follow the manufacturer's installation instructions meticulously. Regular maintenance and inspection of seals can also help prevent unexpected downtime. Signs of wear or damage, such as fluid leakage or visible cracking, should prompt immediate attention.

Conclusion

Understanding the dimensions of shaft seals and their importance is critical for anyone involved in the design, maintenance, or operation of machinery that utilizes these components. Accurate measurements of the inner diameter, outer diameter, and width, combined with the correct material selection, are pivotal in ensuring proper sealing performance. Adhering to industry standards during selection and installation processes can significantly enhance the reliability and lifespan of machinery. As we continue to innovate and improve mechanical systems, the role of effective sealing solutions remains indispensable, forming the backbone of operational efficiency and equipment longevity.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories