High-Quality Shaft Water Seal | Reliable Solutions for Sealing Applications

Understanding Shaft Water Seals An Essential Component in Equipment Efficiency

Shaft water seals are critical components in various mechanical systems, particularly in applications involving water and other fluids. Their primary purpose is to prevent the leakage of water or other fluids from the system while ensuring that contaminants do not enter. These seals play a vital role in maintaining operational efficiency, safeguarding machinery, and extending equipment lifespan.

Construction and Operation

Shaft water seals are typically constructed from durable materials such as elastomers, metals, or a combination of both. The design often includes a flexible sealing lip that makes contact with the rotating shaft, creating a barrier against leakage. When the shaft turns, the seal’s lip adjusts to the shaft's movement, maintaining a tight seal while minimizing wear. This adaptability is crucial, as it allows the seal to function effectively at varying speeds and conditions.

The dynamic sealing action is facilitated by a thin film of liquid that forms between the shaft and the sealing surface. This film helps reduce friction and heat generation, enhancing the seal's performance. However, if the seal is not maintained or properly installed, it can lead to water or fluid leakage, which can result in significant damage to machinery and operational downtime.

Applications

Shaft water seals are utilized in a plethora of industries and applications. In marine environments, they are essential in keeping water out of propulsion systems, ensuring that engines and gearboxes operate smoothly. Similarly, in the agricultural sector, these seals are found in irrigation systems, pumps, and other equipment that handle water.

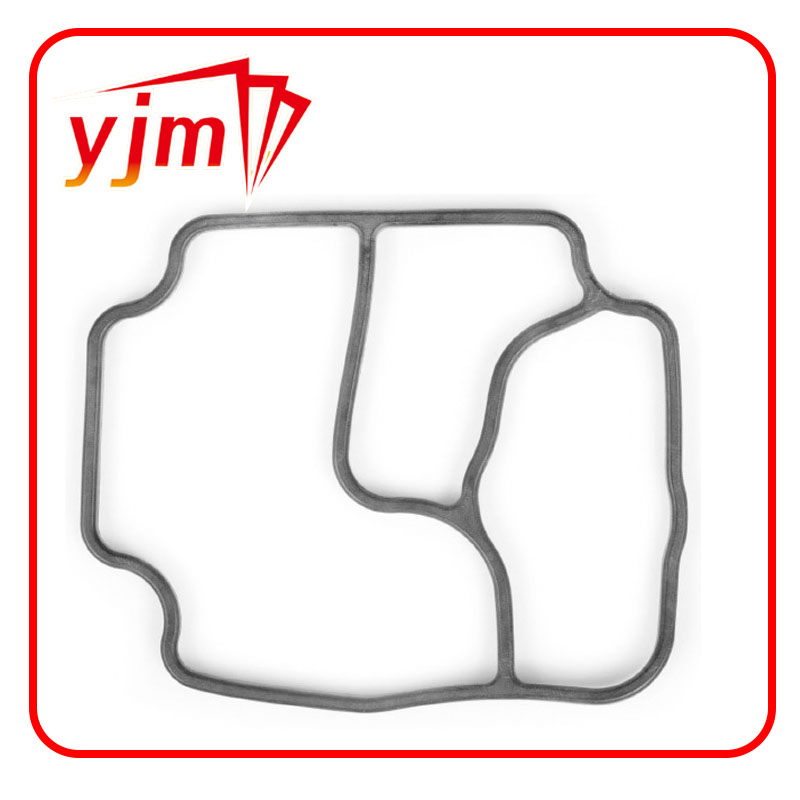

shaft water seal

Additionally, they are used in manufacturing settings, particularly in machinery that requires lubrication and cooling, such as conveyor systems or hydraulics. The seals help prevent costly leaks that can compromise the machinery's efficiency and lead to hazardous working conditions.

Importance of Maintenance

Regular maintenance of shaft water seals is crucial for ensuring their longevity and efficiency. Signs of wear and tear, such as visible leakage or unusual noises from machinery, should not be ignored. An effective maintenance routine may include periodic inspections, cleaning, and replacement of worn seals.

Many industries implement predictive maintenance strategies using advanced monitoring technologies to detect seal performance issues before they lead to significant failures. This approach not only prolongs the life of the seals but also enhances the overall reliability of the equipment.

Conclusion

In conclusion, shaft water seals are indispensable components that play a crucial role in various applications. Their ability to prevent fluid leakage and protect machinery from contaminants helps maintain efficiency and reliability. As industries continue to evolve, the importance of these seals will only grow, highlighting the need for diligent maintenance and innovative sealing solutions. Understanding and addressing the needs of shaft water seals will not only improve machinery performance but also ensure safety and sustainability in operations. Investing in high-quality seals and adopting proactive maintenance practices can significantly impact the operational success and longevity of mechanical systems.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories