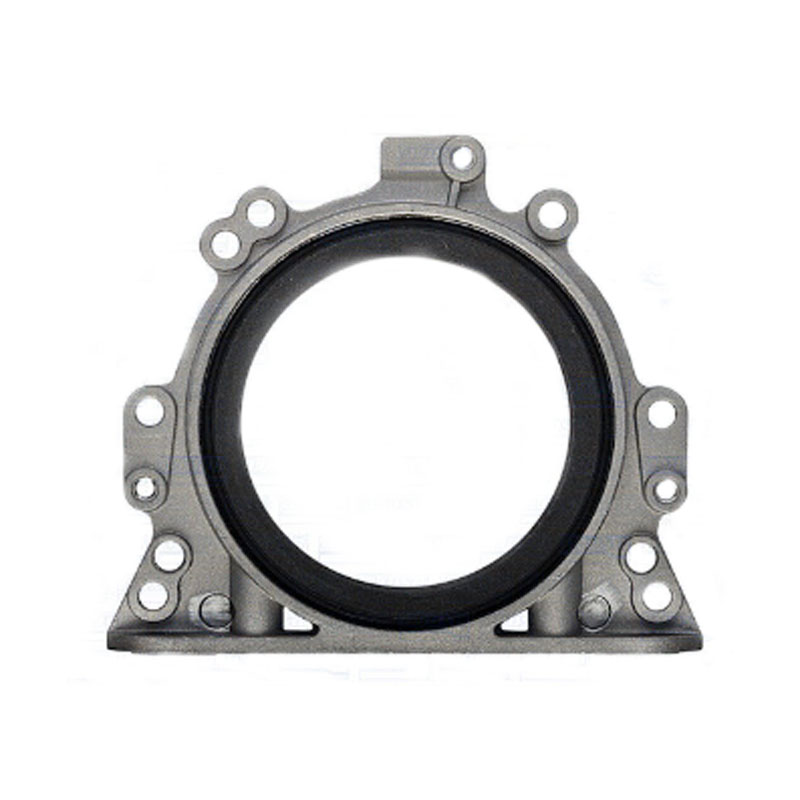

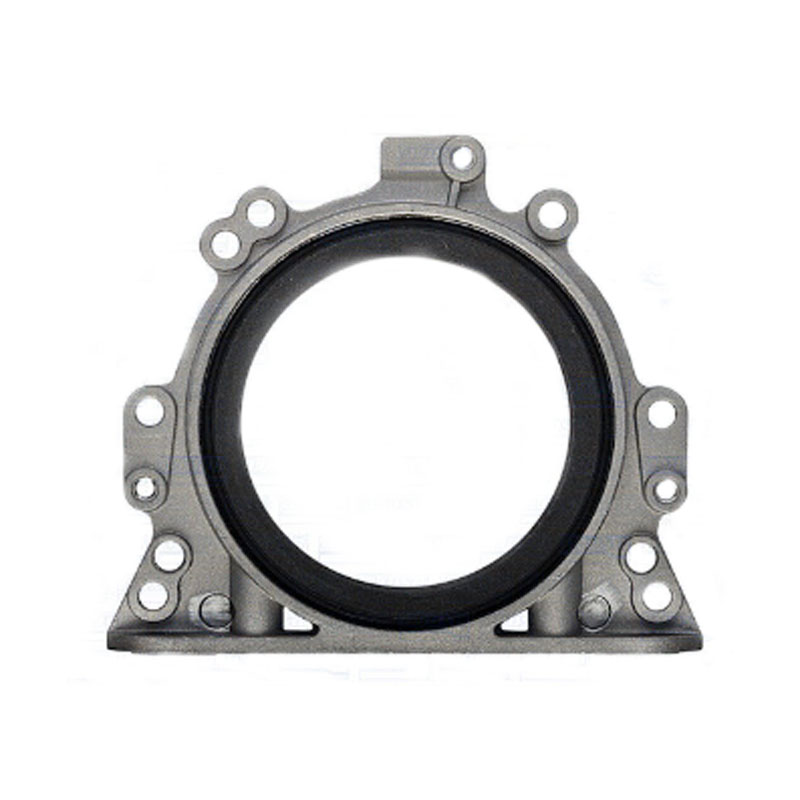

Shaft Seal Differential

Any gaps or misalignment can lead to premature wear and failure of the seal Any gaps or misalignment can lead to premature wear and failure of the seal

Any gaps or misalignment can lead to premature wear and failure of the seal Any gaps or misalignment can lead to premature wear and failure of the seal shaft seal differential. It is also important to follow the manufacturer's instructions for installation and to use the correct tools and equipment.

Maintenance

Regular maintenance is critical for the longevity of a shaft seal differential. It is important to inspect the seal for any signs of wear or damage, and to replace it if necessary. It is also important to keep the surrounding area clean and free of debris, as this can interfere with the proper functioning of the seal. Regular lubrication can also help to extend the life of the seal by reducing friction and wear.

Common Issues and Solutions

There are several common issues that can arise with shaft seal differentials, including leaks, excessive wear, and failure. Leaks can be caused by a variety of factors, including incorrect installation, worn or damaged components, or changes in the pressure or temperature of the sealed fluid. Excessive wear can be caused by misalignment, improper lubrication, or exposure to harsh chemicals. Failure can occur if the seal is unable to withstand the conditions it is subjected to. To address these issues, it is important to identify the root cause and take appropriate action, such as replacing worn components, adjusting the alignment, or using a more durable seal material.

Conclusion

Shaft seal differentials are essential components in many mechanical systems, providing a critical barrier between rotating shafts and preventing the leakage of fluids. By understanding the design, materials, installation, maintenance, and common issues associated with these seals, you can make informed decisions when selecting and maintaining them for your specific application. With proper care and attention, shaft seal differentials can provide reliable performance and long service life.

shaft seal differential. It is also important to follow the manufacturer's instructions for installation and to use the correct tools and equipment.

Maintenance

Regular maintenance is critical for the longevity of a shaft seal differential. It is important to inspect the seal for any signs of wear or damage, and to replace it if necessary. It is also important to keep the surrounding area clean and free of debris, as this can interfere with the proper functioning of the seal. Regular lubrication can also help to extend the life of the seal by reducing friction and wear.

Common Issues and Solutions

There are several common issues that can arise with shaft seal differentials, including leaks, excessive wear, and failure. Leaks can be caused by a variety of factors, including incorrect installation, worn or damaged components, or changes in the pressure or temperature of the sealed fluid. Excessive wear can be caused by misalignment, improper lubrication, or exposure to harsh chemicals. Failure can occur if the seal is unable to withstand the conditions it is subjected to. To address these issues, it is important to identify the root cause and take appropriate action, such as replacing worn components, adjusting the alignment, or using a more durable seal material.

Conclusion

Shaft seal differentials are essential components in many mechanical systems, providing a critical barrier between rotating shafts and preventing the leakage of fluids. By understanding the design, materials, installation, maintenance, and common issues associated with these seals, you can make informed decisions when selecting and maintaining them for your specific application. With proper care and attention, shaft seal differentials can provide reliable performance and long service life. -

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories