Understanding the Importance of Semi Truck Axle Seals for Optimal Performance

Understanding Semi Truck Axle Seals Importance, Types, and Maintenance

Semi trucks are essential for transporting goods across long distances, and their efficient operation relies heavily on various components, among which axle seals play a crucial role. Axle seals are designed to prevent lubricant from leaking out of the axle housing, while also keeping contaminants such as dirt and water from entering. This article delves into the importance of axle seals, the different types available, and tips for proper maintenance.

Importance of Axle Seals

Axle seals are critical for maintaining the integrity and performance of a semi-truck’s drivetrain. The primary function of these seals is to contain the lubrication within the axle assembly. Lubricants reduce friction between moving parts, ensuring smooth operation and reducing wear and tear. If the lubricant leaks out due to a failing seal, several issues may arise, including

1. Increased Friction Without adequate lubrication, the friction between the axle and other components will increase, leading to accelerated wear and potential damage.

2. Contaminant Ingress A damaged or worn axle seal can allow dirt, water, and other contaminants to enter the axle assembly, which can cause corrosion, rust, and other significant problems.

3. Reduced Performance Continuous leaks can lead to decreased performance of the truck, impacting fuel efficiency and overall handling.

4. Potential Breakdowns In severe cases, a failed axle seal could lead to catastrophic axle damage, resulting in costly repairs and potential downtime for the truck.

Types of Axle Seals

There are several types of axle seals used in semi trucks, each designed to meet specific applications and environments

. The most common types include1. Lip Seals These are the most prevalent types of axle seals, made from elastic materials that mold effectively to the axle surface. They provide a reliable barrier against leaks and contaminants.

2. O-ring Seals O-rings are circular seals that fit into a groove and compress against two surfaces to create a seal. They are often used in lower-pressure applications and can be found in various locations throughout the truck.

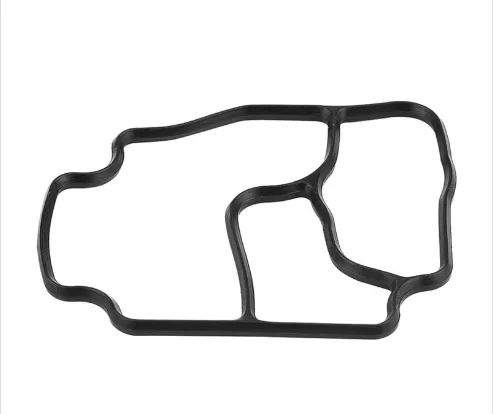

semi truck axle seal

3. Mechanical Seals These complex seals are used in environments that require a high level of sealing reliability, especially in cases of extreme pressure or temperature. They are less common but are available for specific applications.

4. Custom Seals For unique requirements, manufacturers often produce custom seals tailored to specific dimensions and functionality needs.

Maintenance and Inspection

To prolong the life of axle seals and ensure optimal performance, proper maintenance is essential. Here are some tips

1. Regular Inspections Perform routine inspections of the axle seals, especially during scheduled maintenance checks. Look for signs of wear, cracks, or fluid leaks.

2. Lubrication Levels Regularly check and maintain appropriate lubricant levels in the axle. Low levels can lead to overheating and increased friction, which can further damage the seals.

3. Environmental Considerations Be aware of the environments in which your semi truck operates. Excessive exposure to road salt, mud, and extreme temperatures can significantly impact seal durability.

4. Prompt Repairs If a leak is detected, address it immediately. Failing to replace a damaged seal can lead to more extensive repairs and downtime.

5. Professional Evaluation Consider having a professional evaluate the condition of your axle seals as part of regular truck maintenance. They can provide insights and recommendations based on their findings.

Conclusion

Axle seals may seem like minor components in the grand scheme of a semi truck's operations, but they are vital for ensuring the efficiency, reliability, and longevity of the vehicle. Understanding their importance, knowing the types available, and committing to regular maintenance can help truck owners and operators avoid costly breakdowns and ensure a smoother, more reliable driving experience on the road. Investing time and resources into maintaining these crucial components can ultimately lead to significant savings and a more efficient transport operation.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories