Understanding Semi-Trailer Hub Seals for Better Maintenance and Performance

Understanding Semi-Trailer Hub Seals A Key Component for Safety and Efficiency

Semi-trailers are an essential part of the logistics and transportation industry, playing a crucial role in the movement of goods across vast distances. One of the critical components that ensure the longevity and proper functioning of semi-trailers is the hub seal. This article will delve into what hub seals are, why they are important, and how to maintain them for optimal performance.

What is a Hub Seal?

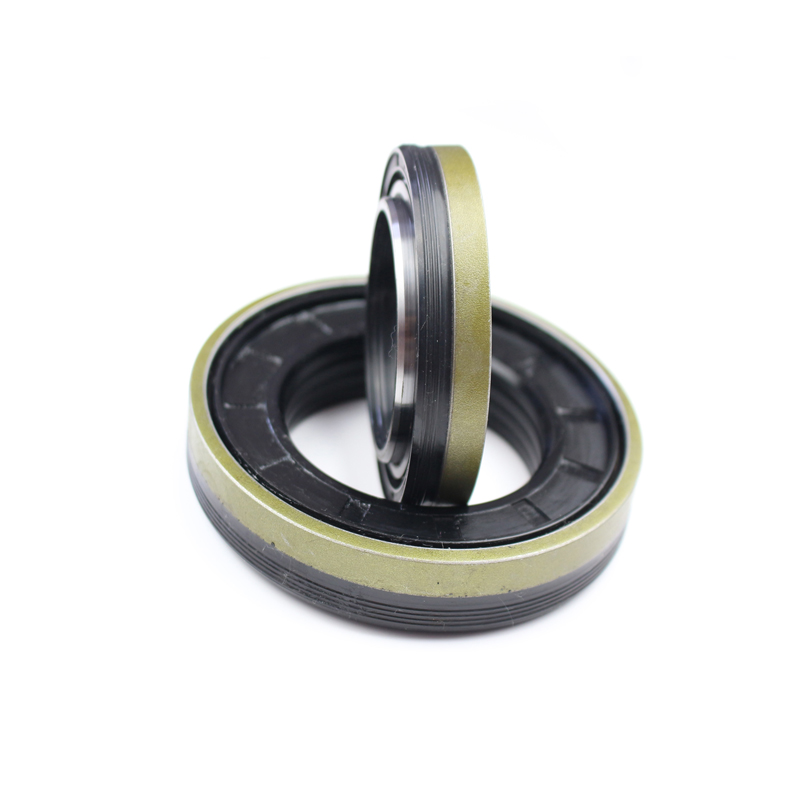

A hub seal is a component located at the wheel end of a semi-trailer, designed to prevent lubricant leakage from the axle and to protect the wheel bearings from dirt, water, and other contaminants. Generally made from durable materials such as rubber or silicone, hub seals are engineered to withstand various environmental conditions and mechanical stresses.

The primary function of the hub seal is to create a tight seal around the axle, ensuring that the grease or oil used in the wheel bearings remains intact. By doing so, hub seals help maintain the necessary lubrication for the bearings, reducing friction and wear, thus prolonging the lifespan of the wheel assembly.

Importance of Hub Seals

1. Protection Against Contaminants One of the most crucial roles of hub seals is protecting the internal components of the axle assembly. Dust, dirt, and water can enter the hub area, leading to corrosion and premature wear of the bearings. By effectively sealing out these contaminants, hub seals ensure that the components remain clean and functional.

2. Lubrication Retention Maintaining a proper lubrication level within the axle is vital for optimal performance. If a hub seal fails, lubricant can leak out, leading to dry bearings and ultimately resulting in failure. A failure in the wheel assembly can cause significant safety risks, including loss of control of the semi-trailer.

semi trailer hub seal

3. Cost Efficiency Regular maintenance and timely replacement of worn or damaged hub seals can save trucking companies considerable expenses. Preventative measures reduce the likelihood of costly repairs or replacements of the axle and wheel components, making regular inspections of hub seals an essential part of vehicle maintenance.

Maintenance and Inspection

To ensure the longevity and effectiveness of hub seals, regular inspections and maintenance procedures should be implemented. Here are some best practices

- Routine Checks During regular maintenance, drivers and technicians should check the hub seals for any signs of wear, cracking, or leaks. A visual inspection can often reveal potential issues before they develop into serious problems.

- Prompt Replacement If any damage is observed, it is crucial to replace the hub seal immediately. Delaying this can lead to more extensive damage and a higher cost of repairs.

- Professional Assistance Utilizing the expertise of qualified professionals for installations and repairs can ensure that hub seals are fitted properly, enhancing their effectiveness and lifespan.

Conclusion

In conclusion, semi-trailer hub seals are vital components that play a crucial role in ensuring the safety, efficiency, and longevity of the trailer's wheel assembly. By understanding their function and importance, and implementing effective maintenance practices, trucking companies can enhance their operational efficiency and reduce the likelihood of costly breakdowns. Investing the time and resources into maintaining hub seals ultimately pays off by safeguarding drivers, vehicles, and cargo on the road.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories