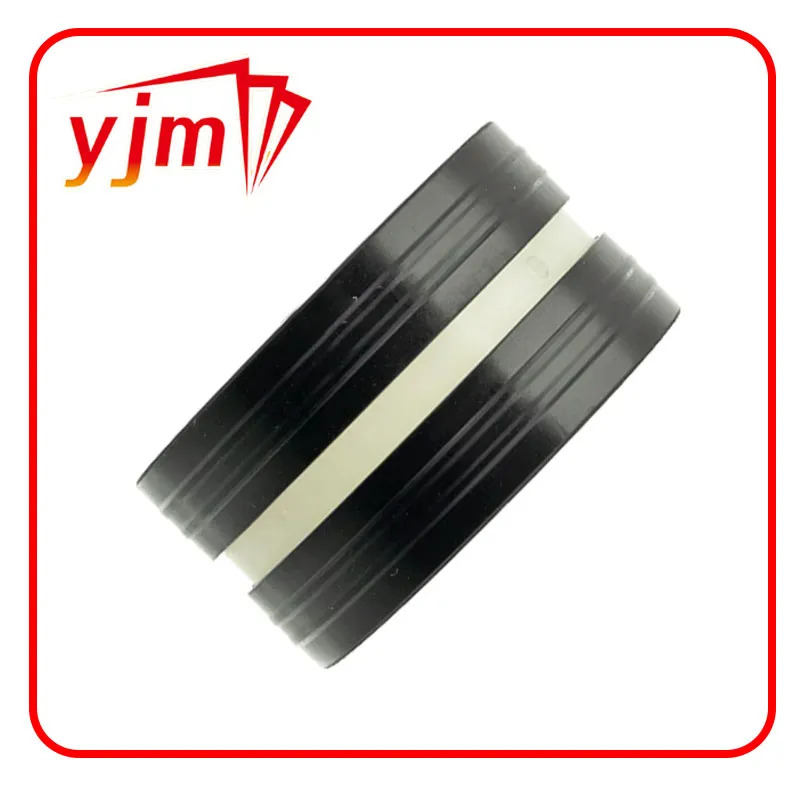

semi pinion seal

Understanding Semi Pinion Seals Function, Importance, and Maintenance

Semi pinion seals are essential components in various mechanical systems, particularly in automotive and industrial applications. They play a crucial role in ensuring the efficient operation of gear systems by preventing the leakage of lubricants and contaminants. In this article, we will explore what semi pinion seals are, their functions, and why they are important, along with tips for maintenance and replacement.

What are Semi Pinion Seals?

Semi pinion seals are specially designed seals that provide a barrier between the rotating pinion gear and the housing in which it operates. These seals are typically made of durable materials such as rubber or composite materials that can withstand high pressures and varying temperatures. They are used in a range of applications, including differentials, gearboxes, and various types of machinery where pinion gears are engaged.

Functions of Semi Pinion Seals

The primary function of semi pinion seals is to prevent the leakage of lubricants. In gear systems, lubricants are vital for minimizing friction and wear between moving parts. If a seal fails, lubricant can leak out, leading to inadequate lubrication, increased friction, overheating, and ultimately, failure of the gear system. Additionally, semi pinion seals prevent dirt, dust, and moisture from infiltrating the gear system, thereby protecting the internal components and maintaining optimal operating conditions.

Importance of Semi Pinion Seals

The importance of semi pinion seals cannot be overstated. They contribute significantly to the overall efficiency and longevity of mechanical systems. By effectively sealing lubricant within the gears, they help maintain consistent performance and reliability. Furthermore, preventing the ingress of contaminants helps reduce the risk of damage to critical components, thus minimizing maintenance costs and downtime due to repairs. In high-performance applications, the integrity of semi pinion seals can be critical, as any failure may lead to significant operational issues.

Signs of Wear and When to Replace

semi pinion seal

Like any mechanical component, semi pinion seals can wear out over time. Several signs indicate that a seal may need to be replaced. These include visible leaks of lubricant around the pinion area, abnormal noises emanating from the gearbox or differential (which may indicate insufficient lubrication), and a decrease in performance or efficiency of the gear system. Regular inspections can help identify these issues early, allowing for timely replacements.

Maintenance Tips

Maintaining the integrity of semi pinion seals is crucial for the longevity and efficiency of your machinery. Here are some tips for effective maintenance

1. Regular Inspections Routinely inspect seals for signs of wear, cracking, or deformation. Early detection can prevent more significant problems down the line. 2. Proper Lubrication Ensure that the lubricant used is appropriate for the application and that levels are maintained within recommended limits. Over or under-lubrication can lead to increased wear on seals.

3. Avoid Contaminants Keep the surrounding area clean to minimize the risk of contaminants entering the system, which can deteriorate seals and other components.

4. Professional Assistance When in doubt, consult with a professional for inspections and replacements. They can offer insights into the best practices for maintaining specific machinery or vehicles.

Conclusion

Semi pinion seals are vital to the proper functioning of gear systems across various applications. Understanding their role, importance, and maintenance needs is essential for anyone responsible for the upkeep of machinery. By ensuring these seals are in top condition, you can enhance the efficiency and reliability of your mechanical systems, ultimately leading to cost savings and improved operational performance. Regular maintenance and timely replacements will go a long way in keeping your equipment running smoothly.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories