Self-Centering Sealed Bonds for Enhanced Performance and Reliability in Applications

Understanding Self-Centering Bonded Seals A Technical Overview

Self-centering bonded seals are innovative sealing solutions that play a critical role in various industrial applications. These seals, often used in conjunction with flanged connections, are designed to provide a reliable barrier against fluid leakage while enhancing mechanical performance. This article delves into the principles, advantages, applications, and installation considerations associated with self-centering bonded seals.

What are Self-Centering Bonded Seals?

Self-centering bonded seals, commonly referred to as Bonded Washers, consist of a rubber sealing element bonded to a metal washer. The unique design of these seals allows for automatic alignment and self-centering during installation. This characteristic is particularly beneficial in applications with misalignment, as it eliminates the operational stress that can lead to premature seal failure.

How Do They Work?

The key to the functionality of self-centering bonded seals lies in their construction. The rubber component is typically made from materials such as nitrile or silicone, which are selected based on the specific application requirements, including temperature resistance and chemical compatibility. The metal washer provides structural support and integrates the seal into the assembly.

When the bonded seal is compressed during the assembly process, the rubber material deforms, creating a tight seal against the mating surfaces. This compressive force ensures that any potential gaps are filled, preventing fluid leaks and providing an effective barrier. The self-centering feature of the seal allows it to adjust and align itself optimally, which is particularly important in applications involving complex geometries or potential misalignment due to thermal expansion or vibration.

Advantages of Self-Centering Bonded Seals

1. Leak Prevention One of the primary advantages of self-centering bonded seals is their ability to prevent leaks under various operating conditions. The tight sealing capability effectively keeps fluids contained, ensuring the integrity of the system.

2. Ease of Installation The self-centering nature of these seals simplifies the installation process. Technicians can achieve proper alignment without complex tools or fixtures, reducing labor time and minimizing the risk of errors.

3. Versatility Self-centering bonded seals can be used across a wide range of industries, including automotive, aerospace, oil and gas, and manufacturing. Their adaptability to different environments makes them a popular choice for engineers seeking reliable sealing solutions.

4. Reduced Maintenance With their long-lasting performance, self-centering bonded seals contribute to reduced maintenance needs. Systems equipped with these seals experience fewer breakdowns due to leaks, promoting increased operational efficiency.

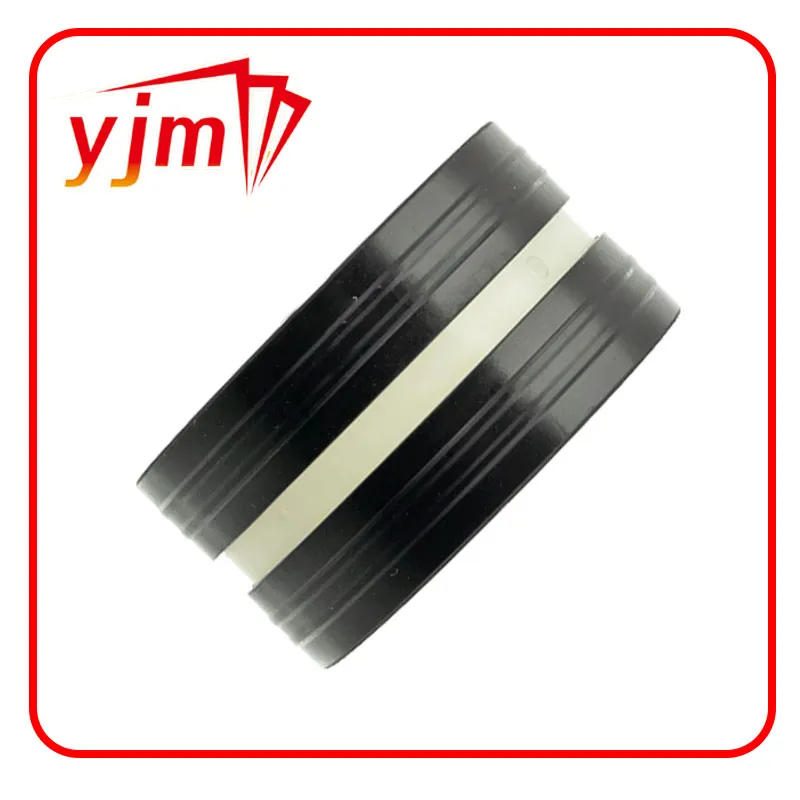

self centering bonded seal

5. Compatibility with Flanged Connections These seals are specifically designed to work with flanged joints where precise alignment is critical. Their ability to accommodate tolerances and slight misalignments makes them a preferred choice for many applications.

Applications of Self-Centering Bonded Seals

Self-centering bonded seals are utilized in various sectors

- Automotive Industry In vehicles, these seals are often used in engine components, transmission systems, and fluid reservoirs to prevent leaks from critical systems.

- Aerospace Aircraft utilize self-centering bonded seals to ensure that fuel and hydraulic systems are leak-free, critical for safety and performance.

- Oil and Gas In drilling and extraction operations, preventing leaks from joints and flanges is essential. Self-centering bonded seals help maintain system integrity in these challenging environments.

- Manufacturing Various machinery and equipment in manufacturing settings employ these seals to prevent fluid loss and maintain operational efficiency.

Installation Considerations

When installing self-centering bonded seals, attention to detail is essential. It's crucial to ensure clean and smooth surfaces to promote the best sealing performance. Additionally, following the manufacturer's recommendations for torque specifications when tightening flanges will help in achieving optimal compression of the seal, ensuring a reliable leak-proof fit.

Conclusion

Self-centering bonded seals offer a robust and versatile solution for preventing leaks in various industrial applications. Their self-aligning capabilities, ease of installation, and reliability make them an excellent choice for engineers and technicians alike. As industries continue to evolve, the demand for effective sealing solutions like self-centering bonded seals will likely remain strong, contributing to more efficient and safer operations across multiple sectors.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories