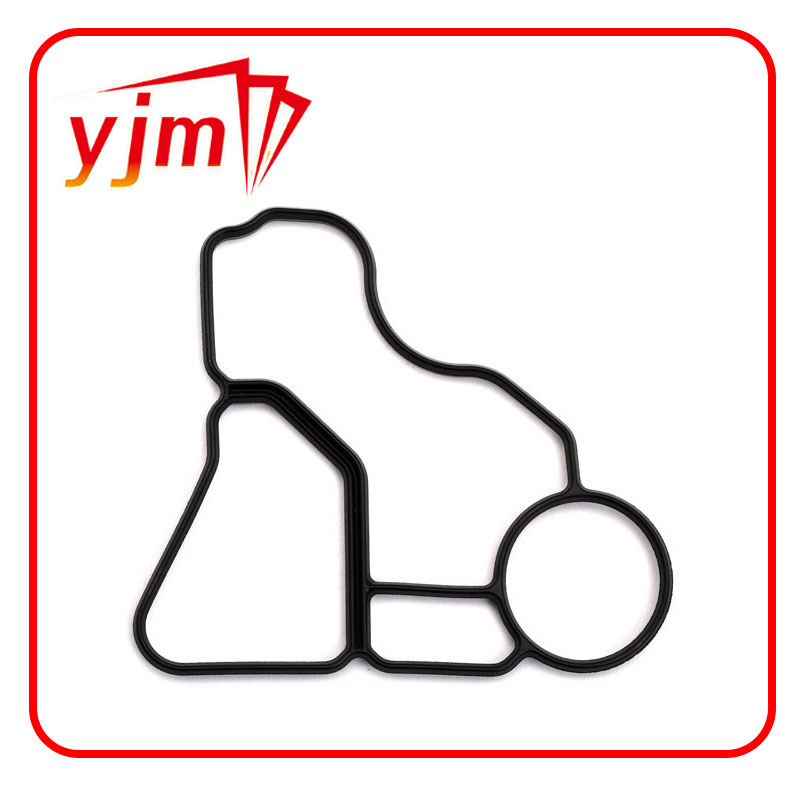

seal ring

The Importance of Seal Rings in Modern Applications

Seal rings, often overlooked in the vast landscape of mechanical components, play a crucial role in various industries. These circular bands, typically made from materials such as rubber, plastic, or metal, are designed to prevent the leakage of fluids and gases in machinery, ensuring efficiency and safety.

In the automotive industry, seal rings are indispensable. They are used in engines, transmissions, and hydraulic systems to maintain pressure and prevent oil or coolant leaks. A failure in a seal ring can lead to severe engine damage, loss of performance, and costly repairs. For instance, the absence of a properly functioning seal ring in an automotive engine can result in oil seeping into the combustion chamber, leading to a smoky exhaust and reduced fuel efficiency. Hence, regular inspections and maintenance of seal rings are vital for vehicle longevity.

Beyond automotive applications, seal rings are essential in the aerospace sector

. Aircraft rely on various mechanical systems where fluid dynamics are critical. Seal rings ensure that hydraulic fluids in landing gears and flight control systems remain contained under extreme pressures and temperatures. The integrity of these seals is paramount to flight safety, as any breach could lead to catastrophic failures during operation.seal ring

Moreover, seal rings are ubiquitous in the oil and gas industry, particularly in drilling and refining processes. These environments often involve high pressures and corrosive substances, making robust sealing solutions essential. Specialized seal rings are designed to withstand harsh conditions, preventing leaks that could not only lead to financial losses but also pose significant environmental hazards.

In the realm of consumer products, seal rings are found in everyday items like kitchen appliances, water bottles, and other containers. They ensure airtight seals that prevent leaks and contamination, enhancing convenience and user experience. The reliability of these seals contributes to product longevity and customer satisfaction, which are critical in a competitive market.

In conclusion, seal rings, though small and seemingly simple, are vital components across various industries. They ensure efficient operation, enhance safety, and prevent costly setbacks. As technology continues to advance, the design and materials used for seal rings will likely evolve, further enhancing their performance and adaptability. Understanding their importance can lead to more informed choices in mechanical design and maintenance, ensuring systems operate smoothly for years to come.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories