Understanding Different Types of Seals Oil Seals, O-Rings, and Their Applications

Understanding Seal Oil, Oil Seals, and O-Rings Key Components in Mechanical Sealing

In the world of mechanical engineering and industrial applications, sealing solutions play a crucial role in ensuring the longevity and efficiency of machinery. Among the various sealing components, seal oils, oil seals, and O-rings are fundamental elements that maintain the integrity of systems by preventing leaks and contamination. This article explores these components, highlighting their functions, applications, and importance in various industries.

What is Seal Oil?

Seal oil is a lubricant specifically formulated to enhance the performance of sealing devices such as oil seals and O-rings. It serves multiple purposes reducing friction, preventing wear, and providing a barrier against environmental contaminants such as dust and moisture. Seal oil is particularly important in applications where equipment operates under high temperatures or extreme pressure conditions. Using the right seal oil ensures that sealing components function optimally, extending their service life and reliability.

Oil Seals Essential Protection for Machinery

Oil seals, also known as shaft seals, are critical components designed to contain lubricants within machinery while preventing the ingress of external contaminants. They are typically made from elastomeric materials (rubber-based materials) and feature a metal or rigid outer casing. This construction allows for durability and resistance to various lubricants, temperatures, and pressures.

Oil seals are commonly found in various applications, including automotive engines, pumps, gearboxes, and industrial machinery. Their primary function is to prevent oil leaks from the system, which can lead to significant operational problems, including reduced efficiency and potential damage to machinery. Proper installation and selection of oil seals are essential for optimal performance. Factors such as the type of lubricant used, operational temperature, and rotational speed must all be considered when selecting the appropriate oil seal.

O-Rings Versatile Sealing Solutions

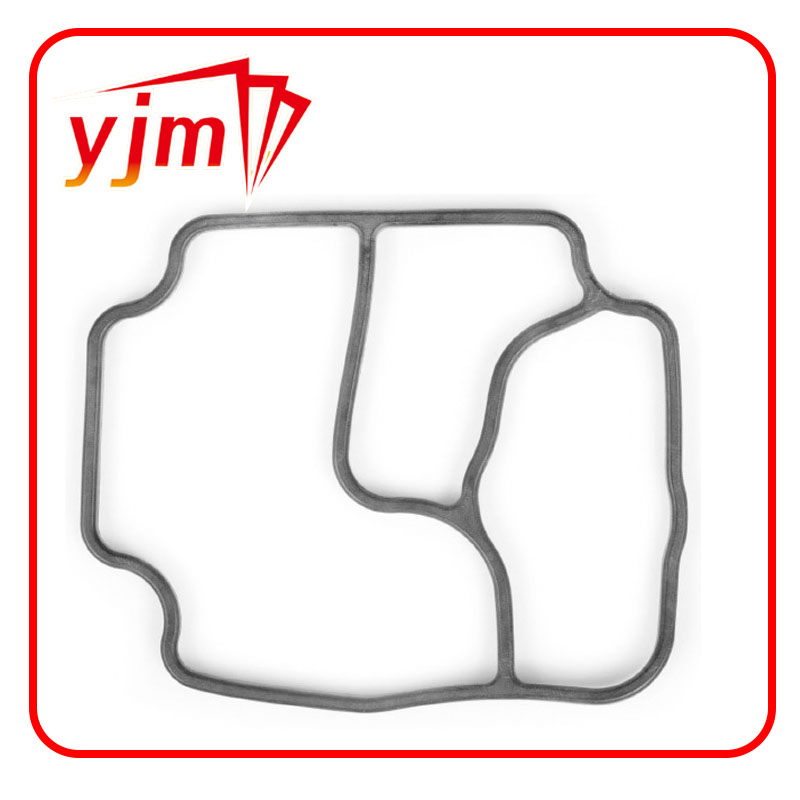

seal oil seal oring seal

O-rings are circular sealing devices that are used in a wide range of applications due to their versatility and effectiveness. They are made from elastomeric compounds, making them flexible and capable of adapting to various mating surfaces. O-rings can be found in hydraulic systems, pneumatic applications, and many other settings where sealing is required.

The primary function of an O-ring is to provide a static or dynamic seal, preventing the leakage of fluids and gases. They can withstand a variety of pressures and temperatures, making them suitable for different environments. In dynamic applications, where the O-ring must move with the machinery, proper lubrication and material selection are critical to minimize wear and prolong service life.

Importance of Proper Sealing Solutions

The significance of using the right sealing solutions, such as seal oils, oil seals, and O-rings, cannot be overstated. Ineffective sealing can result in leaks, environmental contamination, and equipment failure, leading to costly downtime and repairs. The choice of sealing materials and lubricants must be based on the specific requirements of the application, including pressure ranges, temperatures, and exposure to chemicals.

Furthermore, regular maintenance of sealing components can prevent premature wear and ensure that machinery operates smoothly. This includes monitoring for signs of deterioration in O-rings and oil seals, as well as ensuring that seal oils remain effective through their service life.

Conclusion

In conclusion, seal oil, oil seals, and O-rings are vital components that contribute to the reliability and efficiency of machinery across various industries. Understanding their functions and applications helps engineers and maintenance personnel choose the right sealing solutions for their specific needs. By prioritizing proper sealing practices and regular maintenance, organizations can enhance machinery performance, reduce the likelihood of leaks, and minimize downtime, ultimately leading to increased productivity and cost savings. The importance of these sealing components cannot be overlooked, as they play a pivotal role in the efficient operation of countless mechanical systems.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories